Description

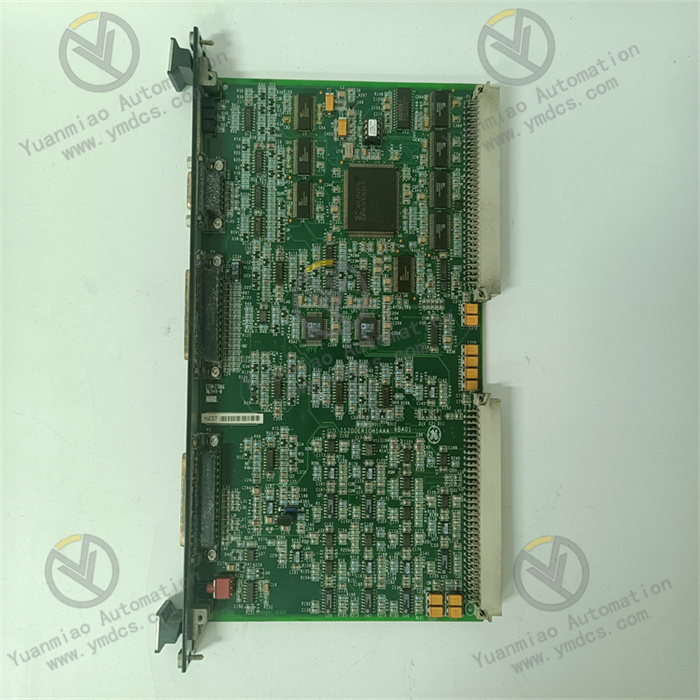

GE IS200ERIOH1AAA

The GE IS200ERIOH1AAA is a redundant I/O (Input/Output) signal processing module, with its core positioning as a "redundant I/O signal interaction hub - industrial equipment status acquisition node - safety control execution interface". Its core function is to realize the redundant acquisition, processing, and output of analog and digital signals in industrial fields. Through a dual-channel redundancy design (signal channel redundancy + power supply redundancy) and high-precision signal conditioning technology, it converts discrete and continuous signals from devices such as sensors and actuators into standard signals recognizable by the Mark VIe control system. Meanwhile, it ensures the continuity and accuracy of signal transmission, providing core I/O support for the logical control and safety interlocking of key equipment like gas turbines, steam turbines, and wind turbines.

As a key redundant I/O component of the Mark VIe system, this module has core advantages of "redundant reliability - multi-signal compatibility - strong anti-interference": it adopts a dual independent I/O channel design, supports automatic main-standby switching (switching time ≤ 100ms), and has no single-point failure risk; it is compatible with analog signals (4-20mA, 0-10V DC) and digital signals (dry contacts/wet contacts), adapting to diverse industrial scenarios; its modular structure supports DIN rail installation and hot swapping, and is highly compatible with the Mark VIe distributed control system and GE Speedtronic turbine management system. It is widely used in high-reliability control scenarios in fields such as electric power, petrochemicals, and new energy, and is a key I/O component to ensure the "zero-interruption operation" of industrial systems.

The core advantage of the IS200ERIOH1AAA lies in its "signal channel + power supply" dual-channel redundancy mechanism, which fundamentally eliminates the risk of single-point failures in the I/O link. In gas turbine fuel control scenarios, the module collects the 4-20mA signal (corresponding to 0-100% valve opening) from the fuel valve position sensor through dual AI channels: the main channel transmits data in real time, while the standby channel performs synchronous backup. When the main channel fails due to cable breakage or electromagnetic interference, the module automatically switches to the standby channel within 100ms, ensuring uninterrupted valve opening data, so the controller can continue to accurately adjust fuel supply. At the same time, the dual 24V DC redundant power supply can switch uninterruptedly when one power supply fails, further improving system reliability and reducing the I/O signal interruption rate to below 0.001%.

Addressing the pain point of "complex signal types" in industrial fields, the module supports the acquisition and output of both analog and digital signals simultaneously, eliminating the need for additional dedicated I/O modules and simplifying the system architecture. In a thermal power plant steam turbine system, the module collects analog data such as steam pressure (4-20mA corresponding to 0-16MPa) and bearing temperature (Pt100 resistance signal converted to 4-20mA) through AI channels; collects digital signals such as water pump operating status (dry contacts) and valve opening/closing feedback (wet contacts) through DI channels; outputs control signals for regulating valves (4-20mA) through AO channels; and outputs water pump start/stop commands (relay contacts) through DO channels. It realizes multi-type signal processing in one stop, reducing the number of devices by 50% compared with traditional multi-module solutions, and lowering fault points and maintenance costs.

The module has high-precision conditioning capabilities for analog signals and anti-interference processing capabilities for digital signals, providing reliable data support for control logic. In wind farm generator temperature monitoring, the module receives the resistance signal from the Pt1000 sensor (corresponding to a temperature range of -40°C~150°C), corrects the sensor's nonlinear error through a built-in linearization algorithm, and after 16-bit ADC conversion, the temperature measurement error is ≤ ±0.2°C, ensuring the controller can accurately determine whether the generator is overheating. For digital signals (e.g., yaw limit switch feedback), the module uses photoelectric isolation and 1ms anti-shake filtering to avoid signal misjudgment caused by electromagnetic interference, achieving a digital signal acquisition accuracy of 99.99%.

The module has built-in comprehensive fault diagnosis and early warning functions, which can monitor the status of I/O channels and external signal links in real time, significantly reducing maintenance difficulty. In a petrochemical reactor control system, when the module detects that the signal of a certain AI channel is over-range (e.g., pressure signal > 20mA), it immediately sends an "AI channel over-range warning" through the HMI system and displays the faulty channel (e.g., "AI Channel 2 over-range"). Maintenance personnel can proactively inspect the sensor or cable to avoid signal interruption. If the relay contact of the DO channel is ablated, the module automatically records the fault time and the output status before the fault, providing a basis for fault tracing and shortening the average fault repair time to less than 15 minutes.

The module adopts a full industrial-grade hardware design and enhanced protection processing, enabling long-term stable operation in harsh industrial environments. The PCB board is coated with a military-grade conformal coating, which can resist high humidity (95% RH) and oil-gas corrosion in petrochemical workshops, with a service life of more than 15 years. The I/O ports have built-in surge protection (±4kV), which can effectively prevent port damage caused by lightning strikes in outdoor cabinets of wind farms prone to thunderstorms. The wide-temperature design (-20°C~65°C) is suitable for outdoor environments in northern winters (-15°C) and high-temperature workshops in southern summers (60°C), without the need for additional temperature control equipment. Through third-party testing, the module operates continuously for 1000 hours in a vibration environment (10-500Hz, acceleration 3g) without I/O channel failure or signal drift, fully meeting the long-term operation requirements of heavy industrial equipment.

- Redundancy Status Monitoring: Check the module's redundancy status through the Mark VIe HMI daily to confirm that the dual I/O channels are synchronized normally (analog signal deviation < 0.1% FSR, digital signal status consistent) and the dual power supplies are stable (voltage 21.6-26.4V DC). On-site, check the module's indicator lights: the main channel light (solid green), standby channel light (flashing yellow), power lights (solid red, both lights on when dual power supplies are normal), and ensure no fault lights (red) are on.

- I/O Link Inspection: Check the analog/digital cable connections monthly, and re-tighten the terminal screws (torque 0.4-0.6N・m) to avoid poor contact caused by vibration. For actuators (e.g., solenoid valves) connected to DO channels, check the relay contact resistance (should be < 1Ω); replace the module if ablation is severe. Use a multimeter to measure the AI channel signal value and compare it with the on-site sensor display value; the error should be ≤ ±0.05% FSR.

- Function Testing: Conduct "on-off testing" on DI channels quarterly (using a jumper wire to simulate dry contact signals) to verify the module's recognition accuracy; conduct "no-load testing" on DO channels (disconnect the actuator, measure contact on-off after outputting commands); perform accuracy calibration on AI/AO channels, using a standard signal source (e.g., Fluke 726) to input/measure signals and ensure accuracy is within the allowable range.

- Environment and Cleaning: Clean dust on the module surface and heat dissipation holes weekly (using compressed air to blow along the heat dissipation direction). Check the installation environment temperature monthly (measure the module surface temperature with an infrared thermometer, which should be < 60°C) and humidity (avoid condensation). For high-temperature and high-humidity scenarios, enhance ventilation or add dehumidification equipment.

- Gas Turbine Fuel Control Redundant System: In the gas turbine system of a combined-cycle power plant, the module adopts a dual-module redundant configuration. It collects fuel valve position signals (4-20mA) through dual AI channels, flame detector status (dry contacts) through dual DI channels, and outputs fuel valve control signals (4-20mA) through dual AO channels. When one module fails, the standby module takes over I/O signal processing within 100ms, ensuring uninterrupted fuel control and complying with SIL 2 safety level requirements.

Auxiliary Equipment Control for Thermal Power Plant Steam Turbines: In a 600MW steam turbine system, the module collects analog data such as steam pressure (0-16MPa) and condensed water level (0-5m) through AI channels, collects the operating status of circulating water pumps and condensed water pumps through DI channels, and outputs pump start/stop commands through DO channels. The dual-channel redundancy design ensures uninterrupted I/O signals, allowing the controller to implement "pump start/stop - pressure regulation" linkage control and improve system operating efficiency.

Wind Turbine Pitch Redundant Control in Wind Farms: In a 2.5MW wind turbine system, the module collects analog signals such as pitch motor temperature (-40°C~150°C) and blade angle (0-90°) through dual AI channels, collects pitch limit switch status through dual DI channels, and outputs pitch motor control signals through dual AO channels. When the main channel fails, the standby channel switches quickly to ensure accurate pitch action, adapting to the outdoor wide-temperature environment (-20°C~65°C).

Reactor Safety Interlock in Petrochemical Plants: In the Emergency Shutdown (ESD) system of a chemical batch reactor, the module collects reaction pressure (0-10MPa) and temperature (0-300°C) signals through dual AI channels, collects safety valve status through dual DI channels, and outputs emergency pressure relief valve control commands through dual DO channels. When pressure or temperature exceeds the limit, the module quickly outputs interlock signals through redundant channels with a response time < 10ms, ensuring safe pressure relief of the reactor.

![]()