Description

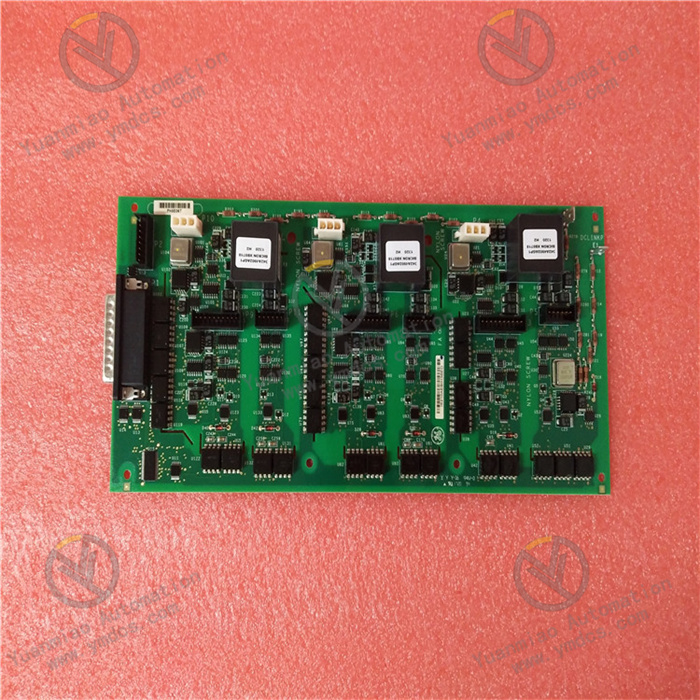

GE IS210AEBIH3BED

I. Core Advantages

(1) Integration of Advanced Technologies

(2) Excellent Durability

(3) Convenient Installation Features

II. Technical Specifications

(1) Electrical Parameters

- Operating Voltage: 220V. This voltage standard is compatible with most industrial power supply environments, enabling stable power acquisition and ensuring the normal operation of the control board in various industrial scenarios.

- Output Frequency: 50kHz. It can realize high-speed signal output, meet application scenarios with strict requirements on signal transmission speed, and ensure timely system response and precise control.

(2) Physical Specifications

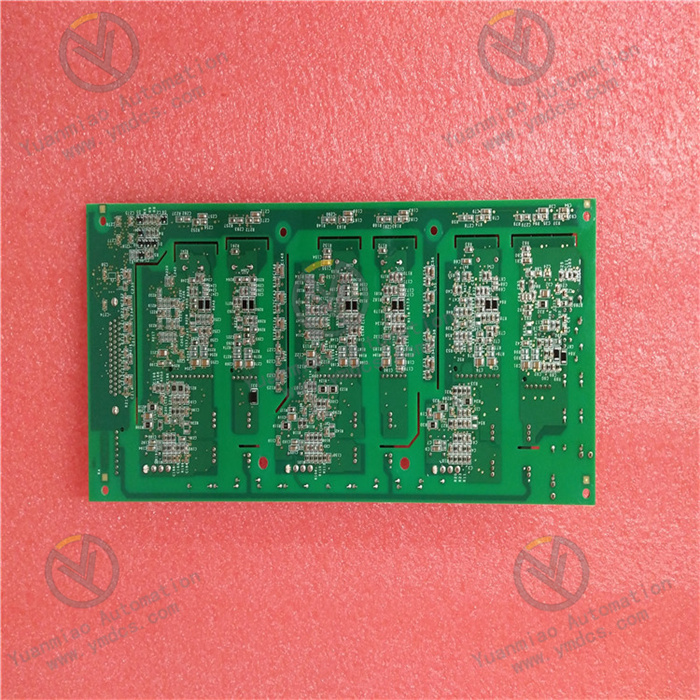

- Dimensions: The length, width, and height are designed to accurately fit the internal space layout of wind turbine control systems. It enables efficient installation and operation in limited space without affecting the overall structural stability of the system.

- Weight: Approximately 0.75 pounds (slight differences may exist in different data). The lightweight design not only facilitates installation and transportation but also reduces the overall load pressure during equipment operation, which is conducive to the long-term stable operation of the equipment.

(3) Hardware Configuration

- Diverse Connectors: It offers a variety of connector options, such as right-angle connectors along the short side, seven vertical pin connectors, and several three-position plugs. These connectors build a bridge for communication between the control board and other components. They can be flexibly selected according to different communication needs and connection scenarios, ensuring stable and reliable data transmission.

Integrated Multiple Components: The board integrates a wealth of components including integrated circuits, diodes, capacitors, resistors, transistors, and three transformers. These components work together to complete a series of complex operations such as signal processing, conversion, and amplification, serving as the hardware foundation for the control board to realize its powerful functions. Meanwhile, some components are marked with reference indicators and individual part numbers, facilitating identification, maintenance, and replacement by maintenance personnel.

III. Functional Features

(1) Signal Processing Function

- Comprehensive Data Acquisition: It can accurately collect analog or digital signals from various sensors, such as temperature sensors, pressure sensors, and flow sensors. During the operation of wind turbines, it comprehensively acquires real-time data from all key parts of the equipment, providing rich and accurate data support for subsequent system analysis and decision-making.

Flexible Signal Conversion: It can convert analog signals to digital signals or vice versa as needed. This flexible signal conversion capability allows the control board to connect smoothly with different types of equipment and systems, expanding its application range and improving system compatibility.

- Reliable Signal Isolation: It has the ability to effectively isolate high-voltage signals from low-voltage signals to prevent mutual interference. In industrial environments, electromagnetic interference generated by the operation of high-voltage equipment can easily affect the accuracy of low-voltage signal transmission. The signal isolation function of this control board ensures stable signal transmission and improves the anti-interference capability of the system.

(2) Control Output Function

IV. Application Fields

(1) Power Industry

- Power Plants: In wind power plants, the GE IS210AEBIH3BED control board serves as a core component and is deeply involved in the full-process control of wind power generation. From the start-up and operation monitoring of wind turbines to the adjustment of power generation output, all rely on its precise control, which provides a guarantee for the stable and efficient power generation of power plants.

- Substations: It is used for the automatic control and monitoring of some equipment in substations. Through the collection and processing of various signals, it realizes real-time mastery of equipment status, timely detects potential faults and hidden dangers, and improves the reliability and safety of substation operation.

(2) Petrochemical Industry

(3) Metallurgical Industry

(4) Marine Industry