Description

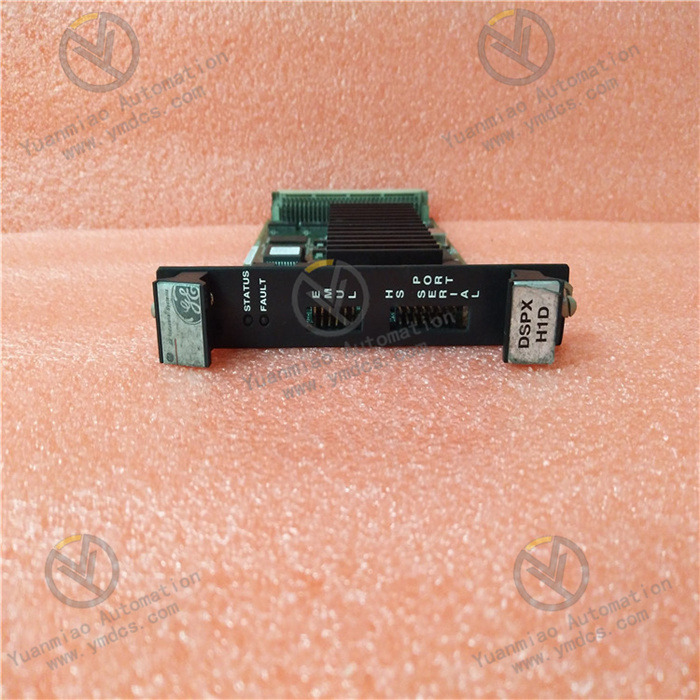

GE IS200DSPXH1DBC

I. Overview

The GE IS200DSPXH1DBC is a high-performance Digital Signal Processor (DSP) control board that belongs to the GE Mark VI turbine control system family. As a core control component within this series, it is specifically designed for medium-to-large gas turbines, steam turbines, and generator excitation systems. Its core positioning is to address the key requirements of industrial turbine equipment, including "real-time processing of multiple parameters, precise control under complex operating conditions, and rapid fault response". It provides an integrated solution encompassing "data acquisition - arithmetic processing - control output - fault early warning" for turbine units in industries such as power generation, petrochemicals, and metallurgy (e.g., steam turbines in thermal power plants, gas compressor-driven turbines in refineries). This ensures the long-term stable operation of turbine equipment under high-load and strong-interference environments, while improving energy conversion efficiency and production safety.

In the control system of a 300MW steam turbine in a thermal power plant, this control board can real-time collect over 20 key parameters, including turbine speed (3000rpm), main steam pressure (16MPa), and shafting vibration (≤125μm). It completes data calculation and control command output within 10ms, controlling the speed fluctuation within ±1rpm to ensure the stable output frequency of the generator (50Hz±0.02Hz), which meets the strict frequency accuracy requirements of the power grid. In the gas turbine-driven centrifugal compressor system in the petrochemical industry, it can dynamically adjust the turbine fuel supply based on the compressor outlet pressure (8MPa) to achieve "pressure-speed" closed-loop control, with a pressure control accuracy of ±0.05MPa, thus avoiding process interruptions caused by pressure fluctuations. In the Ex2100 excitation system of large generators, it can quickly respond to power grid load changes (e.g., load surging from 50% to 100%), adjust the excitation current within 200μs, and maintain the stable terminal voltage of the generator (10.5kV±2%), preventing power grid voltage collapse.

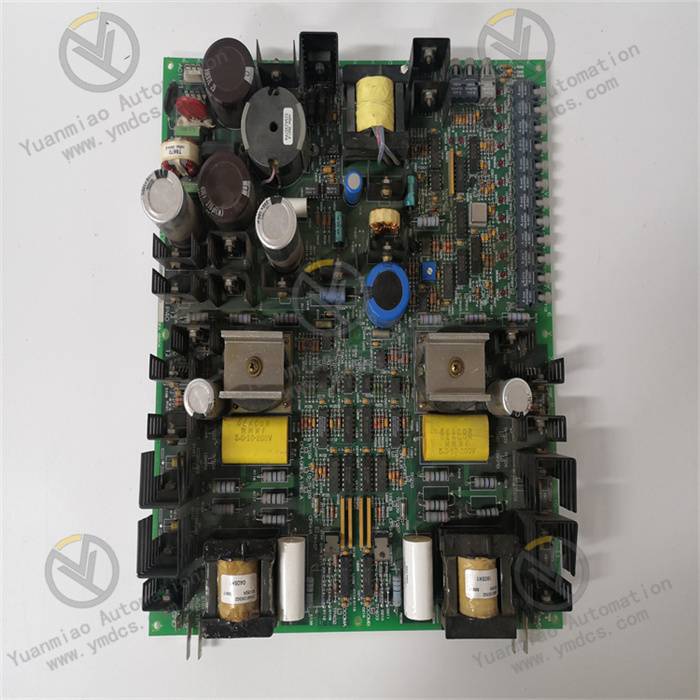

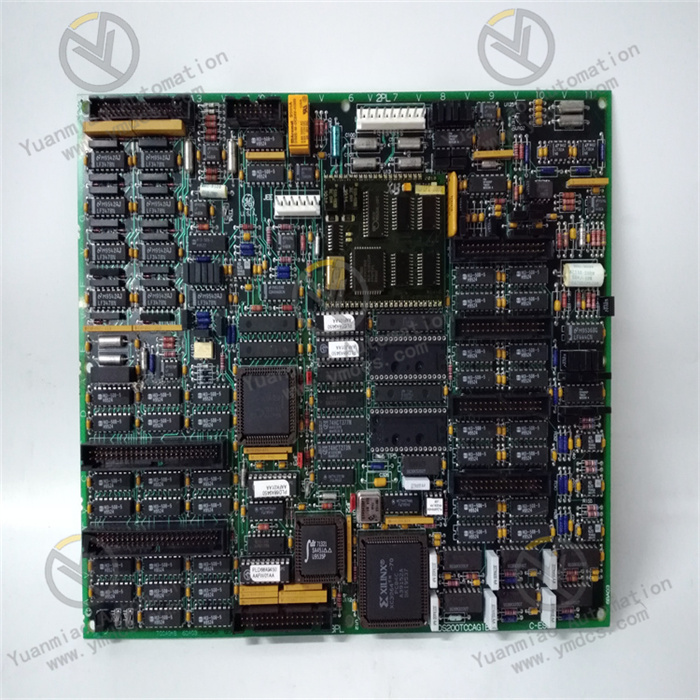

The IS200DSPXH1DBC adopts an industrial-grade compact board structure with dimensions of 180mm×140mm×30mm. It is compatible with slot-type installation in GE Mark VI standard control cabinets and supports the Mark VI system backplane bus. Additionally, it allows parallel expansion of multiple boards (up to 4 units) to meet the multi-loop control needs of complex turbine systems. The board features a multi-layer PCB design, and key chips (such as DSP and FPGA) are equipped with independent heat sinks, enabling it to operate within a temperature range of -40℃ to 70℃. This makes it suitable for extreme environments like steam turbine workshops in power plants (high temperature) and outdoor control cabinets in northern winters (low temperature). Internally, it integrates four layers of hardware protection: "signal isolation - data sampling - arithmetic control - safety interlock". The analog input channels use photoelectric isolation (isolation voltage ≥2kVrms), and the digital output adopts relay isolation, effectively resisting electromagnetic interference in industrial fields (such as high-frequency noise generated by frequency converters). Its Mean Time Between Failures (MTBF) is ≥180,000 hours (per Telcordia standard at 25℃), which meets the "long-cycle, low-maintenance" operation requirements of industrial turbine equipment. Meanwhile, it is compatible with the GE Predix industrial internet platform, supporting remote data upload and fault diagnosis to reduce operation and maintenance costs.

II. Technical Parameters

1. Electrical Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Power Input | Backplane bus power supply: ±5V DC (analog circuit), +3.3V DC (digital circuit); Maximum power consumption ≤15W (full load); Power supply ripple rejection ratio ≥60dB (100Hz-1MHz) |

| Analog Input | 16 differential analog inputs, supporting 4-20mA DC/0-10V DC signals; Sampling accuracy: 24-bit AD, error ±0.02% FS; Sampling frequency: 10kHz (single channel), supporting synchronous sampling |

| Analog Output | 8 isolated analog outputs, supporting 4-20mA DC signals; Output accuracy: 16-bit DA, error ±0.05% FS; Load capacity: ≤500Ω |

| Digital Input | 12 dry contact inputs, supporting 24V DC signals; Response time ≤1μs; Input impedance: 10kΩ |

| Digital Output | 8 relay outputs (normally open/normally closed optional), contact rating 250V AC/5A, 30V DC/5A; Supporting fault interlock output |

| Isolation Protection | Isolation between analog input/output channels ≥2kVrms; Isolation between digital input and power supply ≥1.5kVrms; ESD protection ±8kV (air discharge)/±4kV (contact discharge) |

2. Processing Performance Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Core Processor | TI TMS320C6748 floating-point DSP, main frequency 600MHz; Equipped with Xilinx Spartan-6 FPGA (15k logic units) for real-time logic control |

| Data Processing Capacity | Single-cycle floating-point operation: 1200 MFLOPS; Supporting multi-task parallel processing, maximum task scheduling cycle 1ms; Capable of processing 32 analog signals and 16 digital signals simultaneously |

| Storage Configuration | 512MB DDR3 SDRAM (data cache), 128MB NAND Flash (program storage); Supporting power-off data preservation (fault records, configuration parameters) |

| Control Algorithm Support | Built-in PID/PID cascade (cascade PID), feedforward-feedback control, and fuzzy control algorithms; Supporting user-defined C-language algorithms (compiled via GE ControlST software) |

| Communication Interface Performance | 1 industrial Ethernet (EtherNet/IP, 100Mbps, fastest periodic data update 1ms); 1 RS485 (Modbus RTU, 9600-115200bps); 1 Mark VI backplane bus (40MB/s, for data interaction between boards) |

3. Environmental and Reliability Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Operating Temperature | -40℃~70℃ (wide-temperature design, fanless heat dissipation) |

| Storage Temperature | -55℃~85℃ |

| Relative Humidity | 5%~95% (non-condensing), complying with IEC 60068-2-38 humidity cycle standard |

| Electromagnetic Compatibility | Emission: EN 55022 Class A; Immunity: EN 55024 (EFT ±2kV, surge ±4kV at power port, RF radiation 10V/m) |

| Mechanical Performance | Vibration: IEC 60068-2-6 (10-500Hz, 2g, 2 hours per axis); Shock: IEC 60068-2-27 (15g, 11ms) |

| Mean Time Between Failures (MTBF) | ≥180,000 hours (per Telcordia standard at 25℃) |

4. Safety and Diagnostic Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Safety Function | Supporting SIL 2 safety integrity level (complying with IEC 61508 standard); Built-in Watchdog timer (configurable 1ms-10s), triggering system reset upon timeout |

| Fault Diagnosis | Supporting hardware fault self-diagnosis (DSP, FPGA, AD/DA chips, power supply voltage) with diagnostic coverage ≥98%; Real-time monitoring of board temperature (≤85℃), triggering alarm when temperature exceeds limit |

| Fault Recording | Storing the latest 100 fault records (including fault code, fault time, and key parameters at fault occurrence) with recording accuracy 1ms; Supporting fault log export via Ethernet |

III. Functional Characteristics

1. High-Speed Real-Time Processing of Multiple Parameters

With "fast response and high precision" as its core, the IS200DSPXH1DBC achieves real-time acquisition and calculation of multiple parameters of turbine equipment through the collaboration of a high-performance DSP and FPGA:

- High-Frequency Synchronous Data Acquisition: 16 channels of 24-bit AD support 10kHz synchronous sampling, enabling simultaneous collection of turbine speed, pressure, temperature, vibration, and other parameters with a sampling delay ≤1μs. This avoids control deviations caused by asynchronous sampling. In gas turbine control, it synchronously collects fuel pressure, intake air temperature, and speed to ensure that fuel quantity adjustment matches speed changes in real time, achieving a speed control accuracy of ±0.1rpm.

- Efficient Data Calculation Capacity: The 600MHz floating-point DSP can complete 1200 MFLOPS operations per cycle, supporting the rapid execution of complex control algorithms (such as cascade PID and fuzzy control). In the "main steam pressure - speed" cascade control of steam turbines, the DSP can complete parameter calculations for the main loop (speed) and secondary loop (pressure) within 5ms, reducing speed fluctuation from ±5rpm (with traditional control) to ±1rpm.

- FPGA Real-Time Logic Control: The Xilinx Spartan-6 FPGA is responsible for real-time processing of digital signals (such as speed pulse counting and interlock logic judgment) with a response time ≤1μs, which is 10 times faster than pure DSP control. In turbine overspeed protection, the FPGA monitors speed pulse signals in real time. When the speed exceeds 110% of the rated value, it triggers an emergency shutdown command within 1μs to prevent turbine damage (the response time of traditional DSP control is ≥10μs).

2. Precise Control Under Complex Operating Conditions

In response to the "high load and variable operating conditions" characteristics of industrial turbines, the control board achieves precise control under all operating conditions through flexible control algorithms and adaptive adjustment:

- Multi-Algorithm Adaptation to Different Scenarios: Built-in algorithms such as PID, cascade PID, and feedforward-feedback control can be flexibly selected based on turbine type. In the control of steam turbines in thermal power plants, the cascade PID algorithm (main loop: speed, secondary loop: main steam flow) is adopted. When the power grid load changes suddenly (e.g., dropping from 300MW to 200MW), the secondary loop quickly adjusts the steam flow, and the main loop fine-tunes the speed, reducing the adjustment time from 2s (with traditional PID) to 0.5s. In gas turbine control, feedforward-feedback control is used to adjust the fuel quantity in advance according to changes in intake air temperature, avoiding speed deviations caused by temperature fluctuations.

- Load-Adaptive Adjustment: It supports automatic optimization of PID parameters based on turbine load characteristics, adapting to the entire operating cycle of "start-up - speed-up - rated load - speed-down - shutdown". For example, during the turbine start-up phase, it automatically increases the integral time (I) to avoid speed overshoot; during the rated load phase, it reduces the proportional coefficient (P) to minimize speed fluctuation; during the speed-down phase, it increases the derivative coefficient (D) to accelerate response speed and ensure smooth speed reduction.

- Precise Control of Excitation Systems: It is compatible with the Ex2100 exciter and supports Automatic Voltage Regulation (AVR) and Manual Excitation Control (MEC) modes. When the generator is operating in parallel with the power grid, the AVR mode adjusts the excitation current within 200μs according to power grid voltage changes (e.g., voltage dropping to 9.5kV) to restore the voltage to 10.5kV, achieving a voltage control accuracy of ±0.5%. In MEC mode, operators can manually set the excitation current to meet debugging and emergency needs.

3. High Reliability and Safety Protection

In response to the "non-interruptible and safety-first" requirements of industrial turbines, the control board maximizes system safety and availability through multiple layers of hardware protection and software fault-tolerant design:

- Hardware-Level Safety Isolation: Analog input/output channels use photoelectric isolation, and digital output adopts relay isolation to prevent board damage caused by external signal interference. In the gas turbine system of refineries, high-frequency noise (100kHz-1MHz) generated by on-site frequency converters is suppressed by the isolation circuit, reducing the analog acquisition error from 1% to 0.02%. The power supply terminal is equipped with overvoltage/overcurrent protection (overvoltage threshold: ±6V DC, overcurrent threshold: 5A). When the backplane bus voltage is abnormal, it cuts off the power supply within 10μs to protect the core chips of the board.

- SIL 2 Safety Integrity Level Certification: Complying with the IEC 61508 SIL 2 standard, it supports safety interlock functions (such as overspeed, overpressure, and excessive vibration). In turbine overspeed protection, when the speed exceeds 115% of the rated value, dual redundant channels (DSP and FPGA) simultaneously trigger shutdown commands to ensure reliable execution of the command (if one channel fails, the other channel can still operate normally).

- Fault Self-Diagnosis and Fault Tolerance: It has a built-in hardware fault diagnosis unit that monitors the status of DSP, FPGA, and AD/DA chips in real time. When an AD chip fault is detected, it automatically switches to the backup AD channel (the board has 2 built-in redundant AD channels) and issues an "E03: AD channel fault" alarm to avoid control interruption. It supports board redundancy (1:1 hot backup). When the main board fails, the backup board switches within 10ms without control interruption, meeting the "zero shutdown" requirement of turbine equipment.

4. Convenient Operation & Maintenance and System Integration

Through standardized interfaces and digital operation & maintenance tools, it reduces the difficulty of turbine system integration and maintenance:

- Standardized Communication and Bus Compatibility: Supporting EtherNet/IP, Modbus RTU, and Mark VI backplane bus, it can be seamlessly integrated into the GE Mark VI control system, third-party DCS (such as ABB 800xA and Siemens PCS 7), and the Predix cloud platform. In large power plants, more than 10 IS200DSPXH1DBC boards are connected to the central DCS via EtherNet/IP, allowing operation and maintenance personnel to real-time monitor the board operating status (such as DSP temperature and AD sampling value) and modify control parameters remotely in the control room.

- Visual Configuration and Debugging: It supports parameter configuration (such as PID parameters, sampling frequency, and alarm thresholds), logic programming (ladder diagram/FBD), and online debugging via GE ControlST software. The software has built-in turbine control templates (such as steam turbines and gas turbines), enabling users to complete configuration by only modifying parameters without programming from scratch, reducing the debugging time from 48 hours (traditional method) to 8 hours. It also supports online monitoring of real-time curves (such as speed and pressure trends) to facilitate fault analysis.

- Fault Recording and Remote Diagnosis: It automatically stores 100 fault records (including fault code, time, and parameters) and supports exporting fault logs to the Predix platform via Ethernet. The platform uses AI algorithms to analyze fault patterns (e.g., "excessive vibration occurs at 9:00 every Monday"), predict potential fault risks, and send maintenance reminders in advance. In the turbine control of wind farms, remote diagnosis can detect "vibration increments (5μm per month) caused by bearing wear", allowing maintenance to be scheduled in advance to avoid unexpected shutdowns (the loss from a single shutdown exceeds 100,000 yuan).