Description

GE IS220YDIAS1A

GE IS220YDIAS1A is a digital input/output (I/O) module. Its core positioning is to address the key requirements of large-scale turbine equipment (such as gas turbines, steam turbines, and industrial turbines) for "accurate acquisition of discrete digital signals, reliable output of control commands, signal stability under extreme operating conditions, and rapid response of digital interlocks". In the industrial automation system, this module undertakes core tasks including valve status feedback of turbine equipment, pump start-stop control, fault contact signal acquisition, and safety interlock command output. It provides an integrated solution of "digital signal acquisition - processing - output - interlock" for turbine equipment in industries such as electric power, petrochemicals, and metallurgy (e.g., gas turbine generator sets above 100MW, catalytic cracking turbines in petrochemical plants, and blast furnace blower turbines in iron and steel plants). Compliant with the IEC 61508 SIL 2 safety level and API 670 turbine monitoring standard, it reduces the risks of turbine equipment misoperation and unplanned shutdowns caused by digital signal transmission errors or delays.

IS220YDIAS1A collects 16 channels of valve status signals (e.g., fuel valve on/off, exhaust valve limit) and outputs 8 channels of control signals (pump start-stop, indicator light control) simultaneously. When the status signal of a certain fuel valve is abnormally lost, the module triggers a "signal fault" alarm within 0.5 seconds, avoiding abnormal fuel supply caused by the controller's misjudgment of the valve status (a single abnormality may result in a unit load fluctuation loss of over 100,000 yuan). In the steam turbine system of a petrochemical plant, the module monitors safety signals such as the turbine emergency stop button and vibration over-limit contacts through 8 digital inputs, and links the shutdown valve through 4 digital outputs. When the emergency stop button is pressed, the module outputs a shutdown command within 1ms, preventing safety accidents caused by the continued operation of the turbine (a single accident may result in losses of over 10 million yuan). In the blast furnace blower turbine system of an iron and steel plant, IS220YDIAS1A operates stably in an environment with high and low temperatures (-10℃~70℃) and strong electromagnetic interference, with a Mean Time Between Failures (MTBF) of ≥500,000 hours, meeting the high reliability requirements of turbine equipment for 24-hour continuous oxygen supply to the blast furnace.

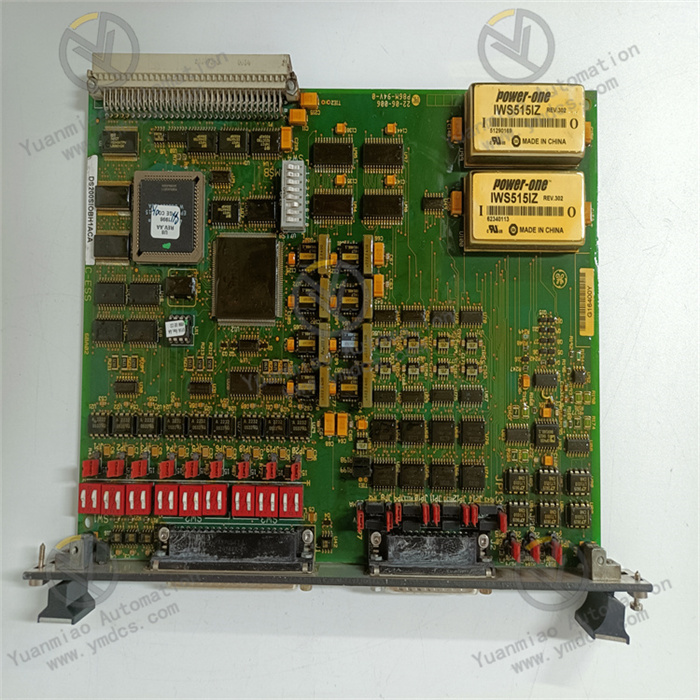

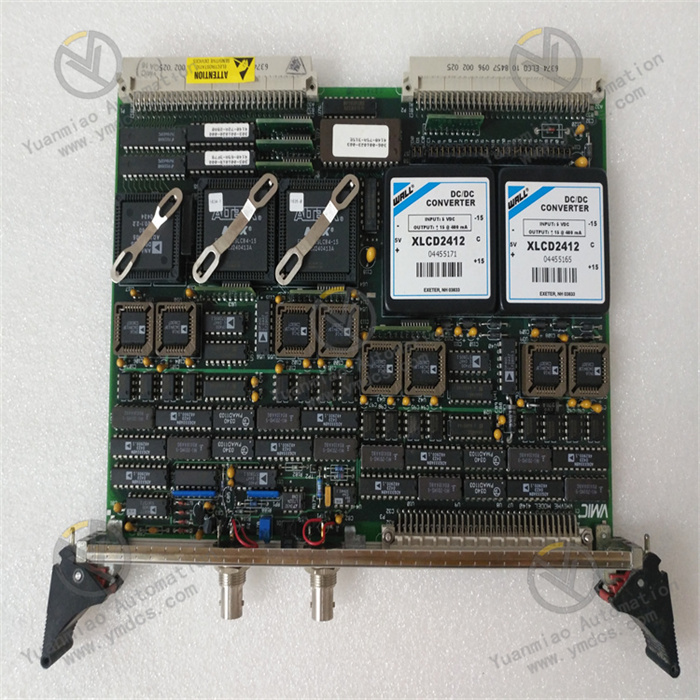

IS220YDIAS1A adopts an industrial-grade reinforced modular architecture, with dimensions of 120mm×80mm×40mm. It is compatible with the standard 3U rack (19-inch rack installation) of the GE Mark VI/Mark VIe system and supports parallel expansion of multiple modules (maximum 16 modules per rack), satisfying the control needs of multiple discrete measurement points for large turbines. Its core adopts a hybrid I/O architecture of "16 digital inputs (DI) + 8 digital outputs (DO)". Each DI/DO channel is equipped with an independent photoelectric isolation circuit and surge protection component, supporting dry contact (no voltage) and wet contact (24V DC) inputs, as well as relay (dry contact) and transistor (PNP/NPN) outputs. The housing is made of UL94 V-0 grade flame-retardant alloy material, with a built-in electromagnetic shielding layer and dust-proof sealing strip, achieving an IP20 protection level to enhance electromagnetic interference and dust protection in industrial sites. The operating temperature range is -10℃~70℃, the relative humidity is 5%~95% (no condensation), and the storage temperature range is -40℃~85℃. Internally, it adopts a "channel-level independent isolation + power filtering" design. The isolation voltage between the DI/DO channels and the backplane bus is ≥2kVrms, and the ESD protection is ±15kV (air discharge), effectively resisting electromagnetic interference generated by high-voltage frequency converters and large motor startups. It is compatible with the GE Control System Toolbox programming software, supports seamless connection with the Mark VIe controller via the PROFINET bus, and enables online configuration and fault diagnosis, reducing the difficulty of system integration.

With "accurate signal interaction" as its core, IS220YDIAS1A ensures the reliability of digital signal transmission through hardware reinforcement and circuit optimization:

- Hybrid channel type adaptation: The 16 DIs can be flexibly configured as dry contacts or wet contacts, and the 8 DOs support relay/transistor output switching, adapting to different on-site equipment without additional hardware. In a gas turbine system, the first 8 DIs collect valve limit dry contact signals, and the last 8 DIs collect sensor wet contact signals; 4 DOs use relay outputs to control high-power pumps, and 4 DOs use transistor outputs to control indicator lights, realizing "integrated processing of mixed signals".

- Low delay and debounce optimization: The DI response time is ≤1ms, combined with adjustable debounce time of 1-200ms. In the turbine system of an iron and steel plant, a 10ms debounce is configured for the mechanical emergency stop button (requiring 10ms debounce) to avoid false alarms caused by contact bouncing; a 1ms debounce is configured for the photoelectric sensor (requiring 1ms debounce) to ensure fast signal response.

- Overvoltage and overcurrent protection: The DI channels support 40V DC overvoltage protection, and the DO channels support short-circuit protection. During the commissioning of a petrochemical plant, a short circuit occurred in the DO channel due to incorrect wiring. The module automatically cut off the output without hardware damage, only triggering a fault alarm, thus reducing maintenance costs.

Aiming at the harsh operating conditions of "strong electromagnetic interference, wide temperature range, and high dust levels" in industrial sites, the module ensures stable operation through multi-layer protection design:

- Electromagnetic isolation and shielding: Each DI/DO channel has 2kVrms photoelectric isolation, combined with the housing's electromagnetic shielding layer. In a power plant turbine system (with 10kV high-voltage motors nearby), the signal-to-noise ratio of the digital signals collected by the module is ≥65dB, with no false transitions.

- Wide temperature and dust-proof design: With an operating temperature range of -10℃~70℃ and industrial-grade components (capacitors with a temperature resistance of -55℃~125℃), the module starts normally without channel failure in outdoor control cabinets in northern winters (-10℃). The IP20 protection level and sealing strip prevent dust from entering the internal circuit during 2 years of continuous operation in the dusty environment of a cement plant.

- Vibration and shock resistance: It can withstand 1.5g vibration at 10-500Hz and 15g shock. The PCB board adopts a reinforcing rib design, and components are in SMD packaging. In the mine turbine system, there is no solder joint detachment or interface loosening under long-term vibration.

In response to the "safety first" requirement of turbine equipment, the module improves system safety through diagnosis and interlock functions:

- Channel-level fault localization: Each DI/DO has independent fault diagnosis (e.g., DI open circuit, DO short circuit). When a fault occurs, fault information is uploaded through LED indicators and the bus. In a turbine system, the 12th DI had an open circuit due to cable aging, and the module detected the fault and alarmed within 100μs, allowing maintenance personnel to quickly locate and replace the cable.

- SIL 2 level safety design: Compliant with the IEC 61508 SIL 2 standard, it supports "fail-safe" output (the DO outputs a safe state such as a shutdown command when the module loses power). In a chemical turbine system, the DO automatically outputs a shutdown signal after the module loses power, preventing turbine runaway.

- Rapid interlock response: The DO output delay is ≤10ms (relay) / 100μs (transistor). In a gas turbine overspeed scenario, after the DI detects the overspeed contact signal, the module outputs a shutdown command through the DO within 0.5ms, cooperating with the controller to achieve "millisecond-level interlock" and prevent rotor overspeed.

Through user-friendly design and standardized tools, it reduces the difficulty of module configuration and operation & maintenance costs:

- Graphical configuration and batch setting: The Control System Toolbox provides an intuitive interface for batch configuration of DI debounce time and DO output type. After configuration, a test report is automatically generated. In a power plant system, the configuration time for 10 modules is reduced from 1 day to 2 hours.

- Status visualization and hot swapping: The module panel is equipped with DI/DO channel LED indicators (green: valid, red: fault), allowing maintenance personnel to judge the channel status without software. It supports hot swapping, and the online replacement time of a faulty module is ≤5 minutes, avoiding shutdown losses in continuous chemical production.

- Remote diagnosis and logging: It supports remote reading of channel status and fault logs (storing the latest 200 fault records) via the PROFINET bus. In cross-regional power plants, technical personnel at the headquarters can remotely troubleshoot faults, saving on-site business trip costs.

![]()