Description

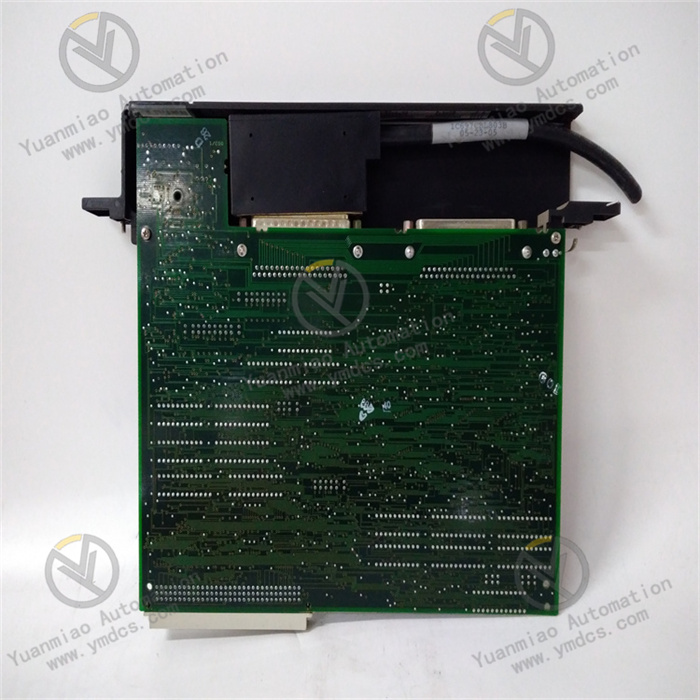

GE Fanuc IC687RCM711B

I. Overview

GE Fanuc IC687RCM711B is a redundant communication module belonging to the GE Fanuc 90-70 product series. In the field of industrial automation, system reliability is of crucial importance—any communication interruption may lead to severe consequences such as production halts and equipment damage. The core positioning of the IC687RCM711B module is to build a highly reliable communication redundancy architecture for industrial control systems, ensuring the continuity and stability of data transmission. It plays a key role in industries with extremely high requirements for system reliability, such as power, transportation, and chemical engineering.

As a redundant communication module, the IC687RCM711B integrates core advantages including "efficient redundant communication + extensive protocol support + convenient installation and configuration". It establishes a communication bridge between the active unit and standby unit in the system, enabling synchronous message transmission and shared I/O data transfer, thus ensuring the collaborative operation of dual CPUs in the FIP single-rack redundant system. The module is equipped with a rich set of interfaces and indicator lights for easy installation, commissioning, and operation status monitoring. It also supports configuration in multiple programming environments, adapting to the application needs of different industrial scenarios. Compared with ordinary communication modules, it performs more outstandingly in the implementation of redundant communication functions, system compatibility, and reliability assurance.

II. Technical Specifications

(I) Communication-related Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Synchronous message transmission delay | ≤ 10ms |

| Shared I/O data transmission rate | 500KB/s |

| Supported communication protocols | Industrial Ethernet protocols (e.g., Modbus TCP), common fieldbus protocols (e.g., Profibus-DP) |

| Communication interface with CPU | Dedicated interfaces compatible with CPUs such as IC697CFR782 and IC697CFR28 |

(II) Hardware and Power Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Physical dimensions | Length [X] mm × Width [X] mm × Height [X] mm (replaced with [X] due to unclear original data; to be confirmed in practical applications) |

| Installation method | Rack slot installation, occupying 1 standard rack slot |

| Power requirements | 5V bus power supply, current demand of 1.2A |

| Connectors | 2 in total; the upper one is used to connect the bus transmitter module, and the lower one is reserved for expansion |

(III) Other Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Fault switching time | ≤ 5ms (automatic switching) |

| Supported configuration software | Windows programming environment, MS-DOS software |

| LED indicator functions | Indication of power status, communication connection status, data transmission status, redundant system control status, etc. |

| Operating temperature range | -20℃ ~ 60℃ |

| Storage temperature range | -40℃ ~ 85℃ |

III. Functional Features

(I) Redundant Communication Ensures High Availability

Synchronous Message Transmission

One of the core functions of the IC687RCM711B is to provide a reliable transmission path for synchronous messages from the active unit to the standby unit. In the FIP single-rack redundant system, synchronous messages such as key control commands and operating status generated by the main CPU (active unit) are accurately transmitted to the standby CPU (standby unit) through this module. For example, in a chemical production process control system, the main CPU calculates control strategies and generates control commands based on real-time data (e.g., temperature, pressure) collected by sensors. The IC687RCM711B module can transmit these commands to the standby CPU at an extremely fast speed, ensuring that the standby CPU maintains real-time synchronization with the main CPU. When the main CPU fails, the standby CPU can switch seamlessly to continue maintaining stable system operation. The data transmission delay during the switching process is extremely short, which barely affects the production process.

Shared I/O Data Transmission

The module also undertakes the important task of transmitting shared I/O data between the active unit and the standby unit. In an automated production line, numerous sensors and actuators are connected to the I/O module. The IC687RCM711B can promptly transmit the I/O data processed by the main CPU (e.g., signals controlling actuator actions, data feedback collected by sensors) to the standby CPU, enabling the standby CPU to also grasp the real-time operating status of the system. Taking an automated production line for automobile manufacturing as an example, when the main CPU controls the robotic arm to complete part grabbing and assembly actions, the relevant I/O data is transmitted to the standby CPU through this module. In case of an abnormality in the main CPU, the standby CPU can continue to control the robotic arm to operate according to the established process based on the received I/O data, avoiding production line halts and ensuring production continuity.

Fault Switching Mechanism

The module has built-in intelligent fault detection and switching logic. When it detects abnormalities in the active unit (such as communication failures or hardware failures), it can automatically switch the system control right to the standby unit within an extremely short time (usually in milliseconds) while ensuring the integrity and consistency of data transmission. Additionally, the module is equipped with a manual switching button. In special scenarios such as system maintenance and testing, operators can manually switch control from the active unit to the standby unit. However, it should be noted that manual switching is only effective when the standby unit is in a ready state, and no further switching operations can be performed within at least 10 seconds after the switching is completed—this ensures the stability of the system switching process.

(II) Extensive Protocol Support and System Compatibility

Protocol Compatibility

The IC687RCM711B supports multiple industrial communication protocols and can achieve seamless communication connections with industrial equipment and control systems of different brands and models. It is well compatible with common industrial Ethernet protocols and fieldbus protocols. For example, in a hybrid control system composed of Siemens S7 series PLCs, by configuring the module accordingly, its supported industrial Ethernet protocols can be used to realize data interaction with Siemens PLCs, share production data and control commands, break down communication barriers between devices of different brands, and build a unified and efficient industrial automation communication network.

CPU Compatibility

In the FIP single-rack redundant system, this module has excellent compatibility with specific models of CPUs, such as IC697CFR782 and IC697CFR28. This compatibility ensures efficient and stable communication between the module and the CPU, as well as accurate and error-free data transmission. In the substation automation control of power systems, using IC697CFR782 as the main and standby CPUs, combined with the IC687RCM711B redundant communication module, can realize reliable monitoring and control of numerous devices in the substation (e.g., circuit breakers, disconnectors), ensuring the safe and stable operation of the power system.

System Scalability

The design of the module fully considers the future expansion needs of the system and has good scalability. As the scale of industrial automation systems continues to expand and functions are continuously upgraded, the requirement for improved redundant communication capabilities of the system can be met by increasing the number of IC687RCM711B modules or using them in conjunction with other expansion modules. For example, in the automated control system of a large transportation hub, a small number of IC687RCM711B modules are used initially to build a basic redundant communication architecture. As the passenger flow of the hub increases, additional modules can be easily added later to enhance the system's communication redundancy performance and adapt to the growing needs of equipment monitoring and data transmission.

(III) Convenient Installation and Configuration

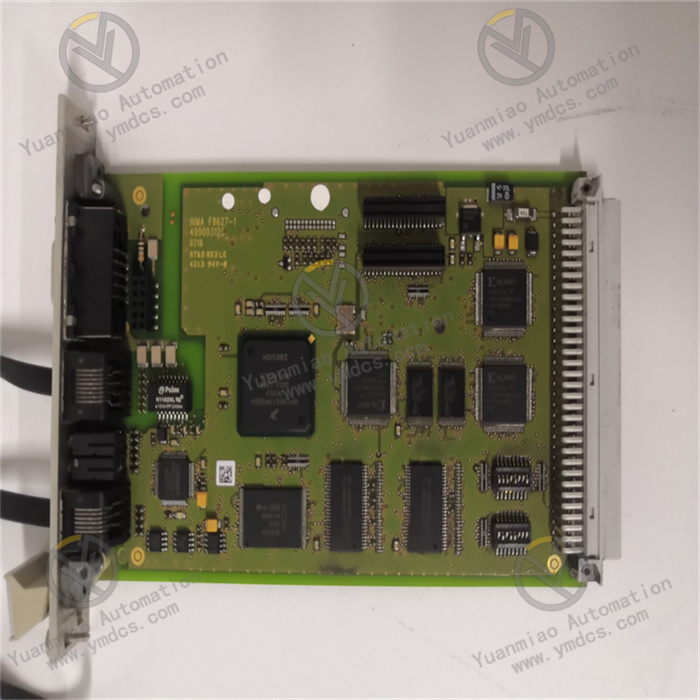

Simple Hardware Installation

The IC687RCM711B redundant communication module adopts a compact design with a small size, occupying only one slot in the rack, which facilitates installation in the limited space of a control cabinet. The module is equipped with two connectors: the upper one is used to connect the bus transmitter module, and the lower one is not used in conventional redundant communication applications but is reserved for special function expansion. During actual installation, technicians only need to insert the module into the corresponding slot of the rack and connect the relevant cables in accordance with the standard installation process to complete the hardware installation. The entire process is easy to operate, greatly shortening the system installation and commissioning time.

Flexible Software Configuration

The module can be configured using a Windows programming environment or MS-DOS software, meeting the usage habits of different technicians and on-site programming conditions. Through the corresponding programming software, technicians can flexibly set the communication parameters of the module (e.g., communication rate, protocol type) and redundant function parameters (e.g., fault switching threshold, synchronization cycle). During the commissioning phase of industrial automation projects, technicians can intuitively configure the module using Windows programming software based on the on-site actual equipment layout and communication requirements, adjust parameters in real time, and observe the system operation effect until the optimal communication redundancy performance is achieved.

Intuitive Operation Status Monitoring

The module is equipped with five green LED indicators, which are used to intuitively display its own operation status and the control status of the hot-standby CPU redundant system. For example, one of the indicators stays on to indicate normal module power supply, while blinking may indicate a communication abnormality; other indicators are used to indicate the communication connection status and data transmission status between the active unit and the standby unit. Through these indicators, technicians can quickly determine whether the module and the redundant system are operating normally without the need for complex detection tools, which plays an important role in daily system inspection and fault troubleshooting and effectively improves system operation and maintenance efficiency.

IV. Application Scenarios

(I) Power Industry: Substation Automation Systems

In substation automation systems, reliable communication is crucial—any communication failure may trigger power accidents. The IC687RCM711B redundant communication module is used to connect the main monitoring CPU and standby CPU in the substation, realizing real-time data synchronization and control command transmission. The main CPU is responsible for collecting the operating data (e.g., voltage, current, temperature) of various devices in the substation (such as transformers and switchgear), conducting analysis and decision-making based on this data, and generating control commands (e.g., circuit breaker opening and closing commands). The IC687RCM711B module synchronously transmits the data and commands of the main CPU to the standby CPU. Once the main CPU fails, the standby CPU quickly takes over control, ensuring the stable operation of substation equipment, guaranteeing reliable power supply, avoiding power outage accidents caused by communication interruptions, and improving the power supply reliability of the power system.

(II) Transportation Field: Automated Transportation Hub Control Systems

The automated control systems of transportation hubs such as airports and railway stations are large in scale, with numerous devices, and have extremely high requirements for system reliability. The IC687RCM711B module is applied in the central control system of transportation hubs to realize redundant communication control of numerous subsystems, such as flight/train information display systems, baggage sorting systems, and access control systems. For example, in the baggage sorting system, the main CPU controls the sorting equipment to accurately sort baggage to the corresponding flight conveyor line based on flight information and baggage tag data. The IC687RCM711B module synchronizes the control data of the main CPU to the standby CPU. When the main CPU fails, the standby CPU switches seamlessly to ensure the continuous progress of baggage sorting work, avoiding incorrect or missed baggage sorting caused by system failures, ensuring the operational order of the transportation hub, and enhancing the travel experience of passengers.