Description

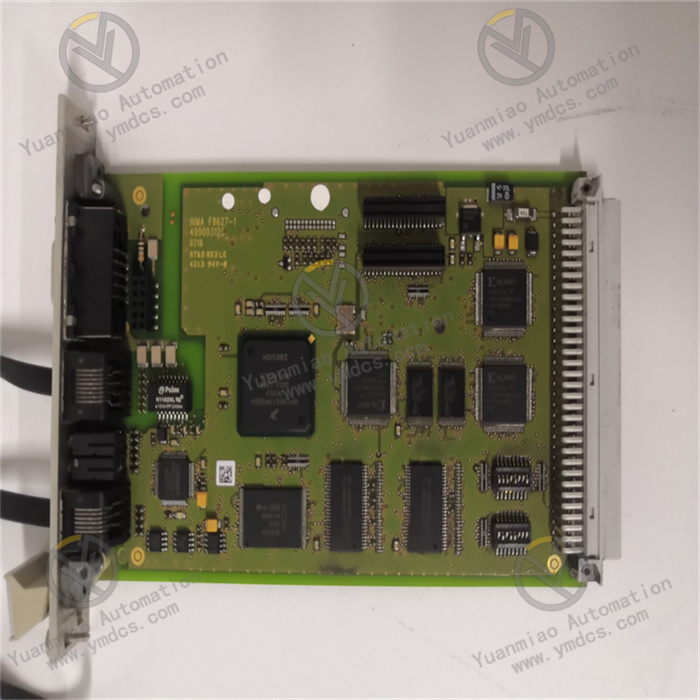

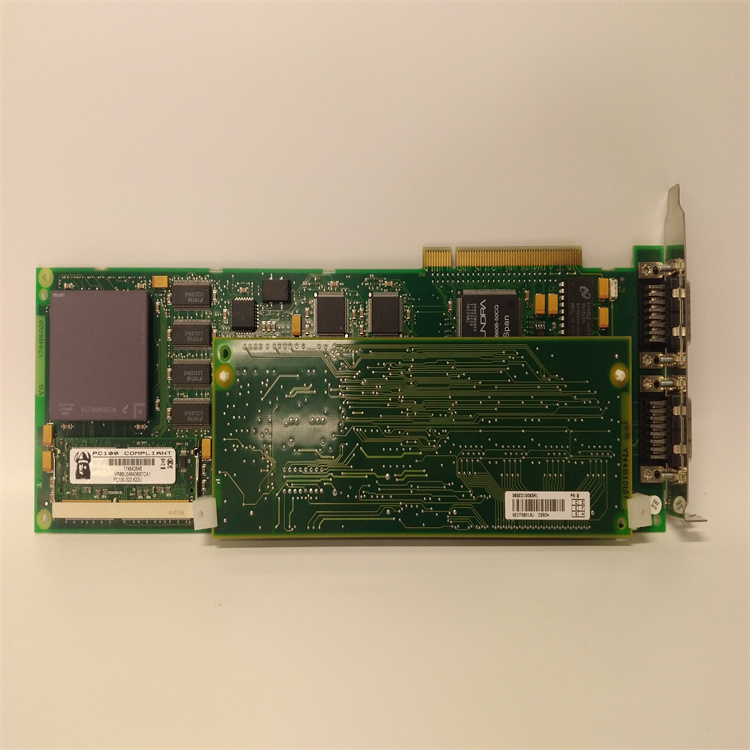

Technical Specifications Processor Performance: It adopts a 32-bit microprocessor and has high data processing and computing capabilities. It can quickly execute complex control logic programs and meet the application scenarios with high real-time requirements in industrial automation. Memory Configuration: It has a certain capacity of Random Access Memory (RAM) for program execution and data storage. At the same time, it may be equipped with Read-Only Memory (ROM) for storing system firmware and user programs. The specific memory capacity may vary depending on the model and configuration. Generally speaking, it is sufficient to support large-scale control programs and data processing tasks. Communication Interfaces: It is usually equipped with a variety of communication interfaces. For example, the Ethernet interface supports network protocols such as TCP/IP, enabling high-speed data communication and networking functions with other devices (such as host computers, other PLCs, intelligent instruments, etc.). In addition, it may also have serial communication interfaces (such as RS-232, RS-485) for connecting and exchanging data with traditional devices or other serial communication devices. Data Processing Capability: It can process various types of data, including digital quantities and analog quantities. For analog data, it can perform high-precision collection, conversion, and processing. For digital data, it can achieve fast logical operations and control outputs. Operating Power Supply: Generally, it requires a stable DC power supply. The common supply voltage is 24V DC, and it has a certain ability to resist power fluctuations to ensure stable operation in an industrial environment. Operating Temperature Range: It can usually work normally within a relatively wide temperature range, generally from 0°C to 55°C, adapting to different environmental temperature conditions in industrial sites. In some special applications, additional cooling or heating measures may be required to ensure its stable performance.

Functional Features Powerful Control Function: It can execute various complex control tasks, such as sequential control, process control, motion control, etc. Through programming languages such as ladder diagrams, instruction lists, and structured text, it can achieve precise control and automated operation of the industrial production process. High Reliability: As an industrial-grade product, the IC697PCM711 uses high-quality electronic components and strict production processes. After strict testing and verification, it has good anti-interference ability and stability. At the same time, it may have redundant designs (such as power redundancy, communication redundancy, etc.) to improve the reliability and availability of the system and reduce the downtime caused by faults. Easy Programming and Debugging: It supports a variety of programming software, such as the dedicated programming software of GE Fanuc. These software have user-friendly interfaces and rich programming tools, making it convenient for engineers to write, debug, and maintain programs. In addition, the module may also have online programming and debugging functions, allowing programs to be modified and optimized without stopping the system operation. Flexible Expandability: It can be used in combination with other modules (such as input/output modules, communication modules, special function modules, etc.), and flexibly expand the functions and scale of the system according to actual application requirements. Through expansion racks and bus connections, it can achieve the control and monitoring of more devices.

Technical Parameters: 1. Processor Type: 32-bit microprocessor Processing Speed: It can quickly execute complex control logic programs. The specific processing speed may vary depending on the specific application and configuration, but generally, it can meet the scenarios with high real-time requirements in industrial automation. Memory Random Access Memory (RAM): It is used for program execution and data storage. The capacity is usually between several hundred KB and several MB. The specific capacity depends on the model and configuration, which is sufficient to support large-scale control programs and data processing tasks. Read-Only Memory (ROM): It is used to store system firmware and user programs, and the capacity also varies depending on the model. 2. Communication Interfaces Ethernet Interface: Protocol Support: It supports network protocols such as TCP/IP, enabling high-speed data communication and networking functions with other devices (such as host computers, other PLCs, intelligent instruments, etc.). Data Transmission Rate: It is usually 10/100Mbps adaptive, which can meet most industrial communication requirements. Serial Communication Interface: Type: It may have RS-232 and/or RS-485 interfaces. Communication Rate: The communication rate of the RS-232 interface is generally between 9600bps and 115200bps; the communication rate of the RS-485 interface can be as high as 1Mbps or above, specifically depending on the device configuration and application requirements. Function: It is used for connecting and exchanging data with traditional devices or other serial communication devices, such as connecting printers, modems, intelligent sensors, etc. 3. Data Processing Capability Digital Quantity Processing: Number of Input/Output Points: The specific number of digital input/output points depends on the connected input/output modules. Through the expansion rack and modules, the control and monitoring of a large number of digital quantities can be achieved. Processing Speed: It can quickly process digital quantity signals, achieve fast logical operations and control outputs, and meet the real-time requirements for digital quantity control in industrial automation. Analog Quantity Processing: Number of Input/Output Channels: Multiple analog input/output channels can be configured, and the specific number varies depending on the module combination. Resolution: It usually has a high resolution, such as 12 bits or 16 bits, which can achieve high-precision analog quantity collection and conversion. Accuracy: The accuracy of analog quantity processing is generally between ±0.1% and ±0.5%, specifically depending on the device model and configuration, which can meet the accuracy requirements for analog quantity measurement in most industrial applications. 4. Operating Power Supply Voltage: 24V DC Current Consumption: The specific current consumption depends on the working state of the module and the connected load, generally ranging from several hundred milliamps to several amperes. Power Supply Fluctuation Range: It can withstand a certain range of power supply fluctuations, usually between ±10% and ±20% of the rated voltage, to ensure normal operation even in the case of unstable power supply in an industrial environment. 5. Operating Temperature Range Normal Operating Temperature: 0°C to 55°C Storage Temperature: -20°C to 70°C

Application Areas Industrial Automation Production Lines: In industrial production lines such as automobile manufacturing, electronic manufacturing, and mechanical processing, it is used to control the operation of production equipment, the transportation of materials, quality inspection, and other links, realizing the automation and intelligence of the production process, and improving production efficiency and product quality. Process Control Industries: Such as the chemical, petroleum, and power industries, it can monitor and control parameters such as temperature, pressure, flow rate, and liquid level in the production process in real time, ensuring the safe and stable operation of the production process, optimizing the production process, and reducing production costs. Energy Management Systems: It is used to monitor and control the production, transmission, distribution, and use of energy, achieving efficient energy utilization and energy conservation and emission reduction. For example, in a smart grid, it can monitor and optimize the scheduling of power production, transmission, and distribution in real time. Transportation Field: In transportation places such as rail transit, airports, and ports, it is used to control the operation of various devices (such as elevators, escalators, lighting systems, ventilation systems, etc.), ensuring the safety and smoothness of transportation.