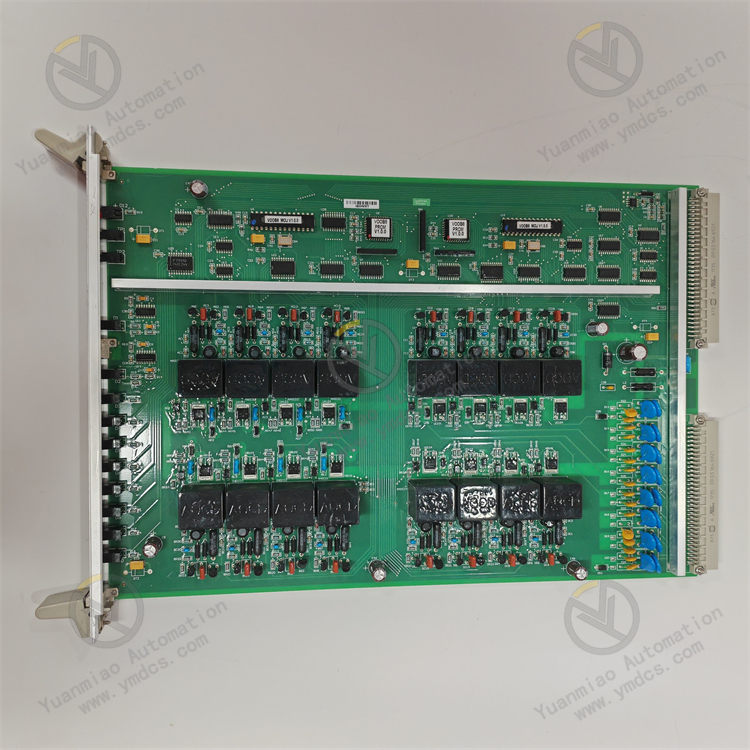

Description

GE IC660TBA026M

As a high-performance analog output module, GE IC660TBA026M plays an important role in this system, providing reliable analog signal output solutions for various industrial applications. It belongs to the GE Fanuc Genius series of products. With advanced technology and stable performance, it is widely used in manufacturing, energy, chemical industry and other industries, providing solid support for the efficient operation of industrial automation.

This module can accurately convert the digital signals output by the controller into analog signals, and then drive various actuators to achieve precise control of industrial production processes. Whether in complex automated production lines or in process links with extremely high control accuracy requirements, IC660TBA026M can ensure the stable and efficient operation of the system with its excellent performance, becoming an indispensable important component in the field of industrial automation.

Output type and range: As a current source analog output module, it mainly outputs 4-20mA analog current signals. This standard signal range is widely used in the field of industrial control and can achieve good adaptation with many industrial equipment. By outputting current signals within this range, the actions of actuators can be precisely controlled, such as the opening of control valves and the speed of motors, meeting the needs for precise control of equipment in different industrial scenarios.

Output accuracy: It has extremely high output accuracy, usually up to ±0.1%, ensuring that the output analog signal highly matches the instructions issued by the controller, and effectively reducing control errors caused by signal deviation. In industrial production processes with strict requirements on control accuracy, such as flow control in chemical reaction processes and batching control in the pharmaceutical industry, this high-precision output characteristic can ensure the stability of the production process and the consistency of product quality.

Power supply requirements: It supports 24/48V DC power input and can adapt to the power environment of various industrial sites. The module integrates an efficient power management circuit, which can ensure a stable working state even when the input power voltage fluctuates to a certain extent, providing a guarantee for the stability of the output signal. At the same time, this power input range also conforms to the common power configuration standards in industrial automation systems, facilitating integration with other equipment.

Load capacity: It has strong load driving capacity and can directly drive various loads, such as solenoid valves, small relays, analog actuators, etc. Its output circuit design fully considers the load characteristics, which can meet the working needs of the load while ensuring the reliability and stability of its own work, effectively avoiding output abnormalities or module damage caused by excessive load.

Overall dimensions: Adopting a compact modular design, the overall size is small, which is convenient for installation in various control cabinets. Its specific size design fully considers the actual installation space requirements of industrial sites, and can achieve efficient layout in limited space, providing convenience for system integration. For example, in the control cabinet of an automated production line with tight space, the compact design of IC660TBA026M can effectively save space without affecting its function.

Installation methods: It provides a variety of convenient installation methods, commonly including rail mounting and screw fixing installation. The rail mounting method uses a standard DIN rail, and the module is quickly and firmly installed on the rail through clips. The installation and disassembly process is simple and fast, facilitating the replacement of modules during system maintenance or upgrade. Screw fixing installation is suitable for occasions with high requirements for installation stability. Through standard mounting holes, screws are used to fix the module on the mounting plate of the control cabinet, ensuring that the module can maintain stable operation in the complex vibration environment of industrial sites.

Operating temperature range: The operating temperature range is 0°C - 60°C, which can adapt to the temperature environment of most industrial sites. Whether near high-temperature industrial furnaces or in relatively low-temperature cold storage environments, the module can work stably to ensure that the analog signal output is not affected by temperature changes. In the non-working state, the storage temperature range is wider, ranging from -40°C to 85°C, which enables the equipment to effectively withstand extreme temperatures during long-term idle or transportation, ensuring that the equipment performance is not damaged and extending the service life of the equipment.

Anti-interference ability: The design fully considers the complex electromagnetic environment of industrial sites. Through measures such as optimizing circuit layout and using shielding materials, it has excellent electromagnetic interference (EMI) resistance. It can effectively suppress the impact of external electromagnetic interference on analog signal output, ensure the accuracy and stability of the output signal, and guarantee the reliable operation of industrial automation control systems in strong electromagnetic interference environments. For example, in industrial environments with strong electromagnetic interference generated by large motors and high-frequency equipment, IC660TBA026M can still stably output accurate analog signals, providing reliable data support for the control system.

Precise control of actuators: With its high-precision 4-20mA analog current signal output capability, it can precisely control the actions of various actuators. In automated production lines, the output signal can be used to precisely adjust the speed of the motor to achieve precise control of the material conveying speed; in chemical production, it can accurately control the opening of the control valve to adjust the flow of fluid in the pipeline, ensuring that the production process runs stably according to preset process parameters, effectively improving production efficiency and product quality.

Strong signal stability: The module uses advanced signal processing technology and high-precision electronic components, which can effectively reduce signal fluctuations and noise interference, and ensure the stability of the output analog signal. During long-term continuous work, the stability of the output signal can still be reliably guaranteed, providing continuous and accurate control signals for industrial control systems, and avoiding equipment misoperation or production failures caused by unstable signals.

Compatibility with multiple controllers: It can be well compatible with GE Fanuc Genius series and other mainstream brand controllers, and can be easily connected to different types of industrial automation control systems. Whether it is a small PLC-based control system or a complex DCS distributed control system, IC660TBA026M can achieve seamless connection with the controller in the system, realize accurate output of analog signals and collaborative work of the system, and provide users with flexible system construction schemes.

Support for multiple communication protocols: It supports multiple industrial communication protocols, such as Modbus, facilitating data interaction and communication with other equipment in the system. Through these communication protocols, the controller can send control commands to IC660TBA026M in real-time to adjust the analog signal output value; at the same time, the module can also feed back its own working status and other information to the controller, realizing intelligent management and monitoring of the system, and improving the overall operating efficiency and reliability of the industrial automation system.

Hardware reliability design: It is made of high-quality electronic components and durable shell materials through strict production processes, ensuring the stability and reliability of the hardware. The internal circuit design fully considers anti-interference measures such as electrical isolation and filtering, reducing interference between internal and external signals of the module, and improving the anti-interference ability of the system. At the same time, key components are redundantly designed. For example, some circuits have redundant backup functions. When a circuit fails, the redundant circuit can automatically switch to work, ensuring uninterrupted operation of the system and reducing the risk of production shutdown caused by hardware failures.

Built-in diagnosis and protection functions: The module has built-in perfect diagnosis and protection functions, which can monitor its own working status in real-time. When abnormal conditions such as overcurrent, overheating, and output short circuit are detected, corresponding protection measures will be taken immediately, such as cutting off the output and issuing an alarm signal, to avoid further expansion of the fault and protect the safety of the module itself and the connected equipment. At the same time, through the diagnosis function, the fault point can be quickly located, providing accurate fault information for equipment maintenance personnel, shortening equipment maintenance time, and improving equipment availability.

Automobile manufacturing: In automobile manufacturing production lines, IC660TBA026M can be used to control various automation equipment. For example, in the assembly of auto parts, the movement of the mechanical arm is precisely controlled by outputting analog signals to achieve precise grasping and assembly of parts, improving assembly accuracy and efficiency; in the automobile painting process, this module is used to control the spraying flow and pressure of the spray gun to ensure that the paint evenly covers the car body and improve the appearance quality of the car.

Electronic manufacturing: In the automated SMT production line of the electronic manufacturing industry, IC660TBA026M can control the movement speed and force of the placement head of the placement machine to ensure that electronic components are accurately placed on the circuit board, improving the yield of SMT production; in the electronic product testing link, the parameters of the testing equipment are controlled by outputting analog signals to achieve accurate testing of the electrical performance and functional parameters of electronic products, ensuring that the quality of electronic products meets the standards.

Power system: IC660TBA026M plays an important role in power generation, transmission, distribution and other links. In power plants, it can be used to control the speed regulation system of generator sets. By outputting analog signals to adjust the air intake of the steam turbine, the speed and output power of the generator can be precisely controlled to ensure the stability of power supply; in substations, it can control the switching of reactive power compensation equipment. By adjusting the output analog signals, the power factor of the power grid is optimized, the power transmission efficiency is improved, and the line loss is reduced.

Petrochemical industry: In the petrochemical production process, IC660TBA026M is widely used in various process controls. In oil extraction sites, the motor speed of oil extraction equipment can be controlled by outputting analog signals to adjust the oil extraction flow; in chemical production workshops, it is used to control parameters such as temperature, pressure and liquid level in the chemical reaction process. By precisely controlling the opening of the control valve, the safe and efficient progress of the chemical production process is ensured, and safety accidents and production losses caused by improper control are avoided.

Intelligent warehousing and logistics: In intelligent warehousing and logistics systems, IC660TBA026M can be used to control equipment such as stackers and conveyors in automated three-dimensional warehouses. By outputting analog signals to adjust the running speed and lifting height of the stacker, the rapid and accurate storage and retrieval of goods are realized; in the conveyor system, the speed of the motor is controlled to adjust the conveying speed of goods, improving the operating efficiency and accuracy of the warehousing and logistics system, reducing labor costs, and enhancing the level of logistics management.

Automated port loading and unloading: In port loading and unloading operations, this module can be used to control large equipment such as port cranes and ship loaders/unloaders. The lifting, walking, slewing and other actions of the equipment are precisely controlled by outputting analog signals to realize rapid loading and unloading of goods; at the same time, the safety protection devices of the equipment, such as overload protection and limit protection, are controlled by analog signals to ensure the safe and efficient progress of port loading and unloading operations and improve the cargo throughput capacity of the port.

![]()