Description

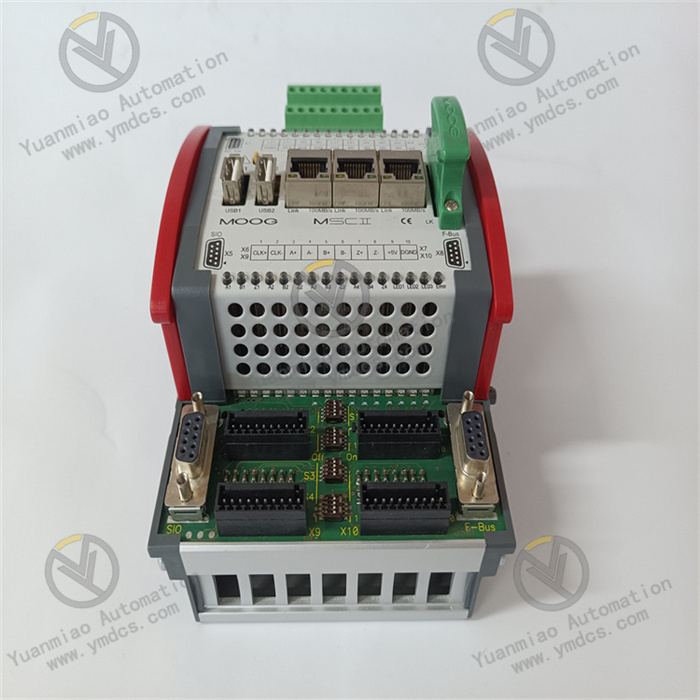

Kollmorgen S72402-NANANA-NA-225

The Kollmorgen S72402-NANANA-NA-225 is a high-performance servo drive with the following characteristics:

Features

- High Control Precision: Utilizes advanced control technology, combining high-precision position feedback with robust motion control to achieve high-speed and high-precision position and speed control, providing smooth motion. Suitable for applications requiring high motion accuracy, such as CNC machine tools and semiconductor manufacturing equipment.

- Fast Response Speed: Capable of quickly reacting to control commands, suitable for applications requiring rapid start/stop and frequent direction changes, such as robotic joint motion control and high-speed sorting equipment in automated production lines.

- High Power Density: Delivers high output power in a compact space, meeting the needs of applications requiring high output torque, such as driving large industrial machinery and controlling elevators and lifting equipment.

- Low Operating Noise: Designed for low noise, smooth operation, and minimal vibration, making it suitable for environments with strict noise requirements, such as medical devices and laboratory automation equipment.

- Strong Reliability: Constructed with high-quality materials and strict manufacturing processes, ensuring long-term stable operation in harsh working environments. Equipped with multiple protection functions, including overcurrent, overheating, and overvoltage protection, to safeguard the drive and motor under abnormal conditions.

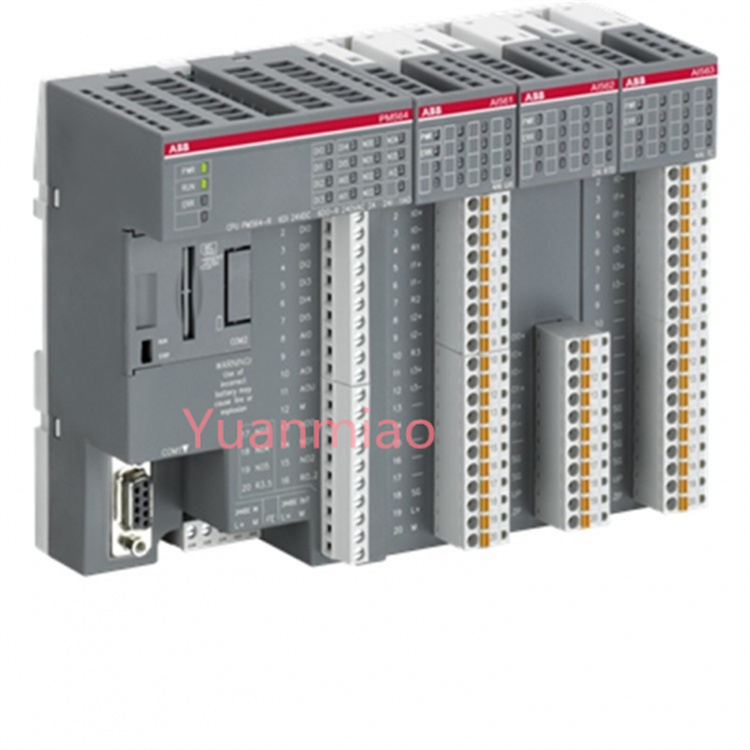

- Good Compatibility: Works with various motion controllers, PLCs, and HMI (human-machine interface) devices. Supports multiple communication protocols and interfaces, such as Ethernet, CAN bus, and pulse direction interfaces, facilitating data exchange and communication with other devices or control systems, and easy integration into different industrial automation systems.

- High Expandability: Allows users to extend and customize the drive program according to specific application requirements. Features multiple control modes, such as speed loop control, position loop control, and torque control. Can connect to high-resolution encoders to obtain precise motion feedback and further enhance its functions through various expansion modules.

- Easy Maintenance: Simple to debug and maintain, with support for a Chinese operating interface and fast interactive fault detection functions, enabling users to adjust parameters and troubleshoot easily, reducing maintenance costs and difficulty.

Technical Parameters

- Operating Voltage: 220V

- Output Frequency: 30kHz

- Communication Interfaces: RS232 interface, 2 CAN expansion modules, supporting communication protocols such as SynqNet, DeviceNet, CANopen, and Ethernet.

- Noise Level: 65dB(A) during operation

- Vibration Rating: Complies with IEC standard 3M1 vibration class

- Operating Temperature: 0°C to 40°C

- Operating Humidity: Up to 85% relative humidity

- Minimum Inductance: 0.7mH

General Working Principle of Servo Systems

A servo system is an automatic control system capable of precisely controlling mechanical motion, primarily composed of four components: controller, driver, motor (servo motor), and feedback device. Its core principle achieves precise positioning, speed, or torque control through closed-loop control.

- Controller

- Function: Receives external commands (e.g., signals from PLCs or motion controllers) and converts them into control signals recognizable by the driver (e.g., pulse signals, analog voltage/current signals, or communication protocol commands).

- Example: Sends position, speed, or torque target values via Ethernet (e.g., EtherCAT, Profinet) or fieldbus (e.g., CANopen).

- Driver (Amplifier)

- Signal Processing: Receives commands from the controller (e.g., target position/speed) and compares them with the actual motor status feedback (e.g., encoder signals) to calculate deviations.

- PID Regulation: Adjusts output current/voltage through proportional-integral-derivative (PID) algorithms to eliminate deviations and make the motor move as commanded.

- Power Amplification: Converts low-power signals into high-power signals to drive the servo motor.

- Function: Amplifies the low-power control signals from the controller into high-power electrical energy required by the motor and adjusts the output based on feedback signals to achieve closed-loop control.

- Workflow:

- Servo Motor

- High Responsiveness: Fast start/stop capability, adapting to high-frequency dynamic control.

- High Precision: Achieves precise position/speed feedback through encoders.

- High Torque Density: Delivers high torque in a compact size.

- Function: Converts electrical energy into mechanical energy to achieve precise rotational or linear motion.

- Types: Commonly permanent magnet synchronous motors (PMSM) or asynchronous motors (induction motors). Kollmorgen products primarily use high-precision PMSMs.

- Key Characteristics:

- Feedback Device

- Encoders (incremental, absolute): Detect position and speed.

- Resolvers: Provide reliable position feedback in harsh environments.

- Current Sensors: Monitor motor current for torque control.

- Function: Real-time detection of the motor’s actual position, speed, or torque, and feedback to the driver or controller to form a closed-loop control.

- Common Types:

Application Fields

- Industrial Automation: Controls robotic arm movements for precise grasping, handling, and assembly tasks; manages conveyor belts in production lines for accurate material transportation and positioning; and enables precise machining in machine tools to ensure processing accuracy and quality.

- Robotics: A key component in industrial and service robots, precisely controlling robotic joint and actuator movements to perform complex tasks, such as path tracking in welding robots and precise spraying in painting robots.

- Medical Equipment: Controls the fine movements of robotic arms in surgical robots to assist doctors in precise operations; manages the movement and positioning of scanning beds in medical imaging devices (e.g., CT, MRI) to ensure imaging accuracy; and operates laboratory automation equipment (e.g., sample processing robots, centrifuges) for precise manipulation.

- Semiconductor Manufacturing: Used in semiconductor production equipment (e.g., lithography machines, etching machines, coating machines) for high-precision position and speed control, ensuring the accuracy and consistency of semiconductor chip manufacturing processes to meet high-precision process requirements.

- Laboratory Automation: Controls experimental equipment such as sample rotating tables for precise angle adjustment; enables accurate positioning of experimental samples or instrument components through positioning systems; and facilitates motion control in laboratory robots to perform various experimental operations.

- Aerospace: Applies to aircraft servo systems for precise control of control surface angles to achieve aircraft attitude control; used in aerospace testing equipment for positioning control and other critical motion control tasks to ensure testing accuracy and reliability.

- Packaging and Printing: Achieves precise transportation of packaging materials, accurate filling of items, and coordinated packaging actions in packaging equipment (e.g., packaging machines, filling machines); controls the rotation of printing rollers, paper feeding, and die-cutting blade positions in printing equipment (e.g., printing presses, die-cutting machines) to ensure printing and die-cutting accuracy and quality.

- Elevators and Lifting Equipment: Used in elevator and lifting equipment control systems to provide smooth movement and precise floor positioning, ensuring passenger safety and comfort while improving equipment operational efficiency and reliability.