Description

GE UCSC H1 IS420UCSCH1A-B

Functional Features

- High Reliability: Designed to industrial standards, it operates stably in harsh environments and is suitable for various industrial automation fields.

- Powerful Processing Capability: Equipped with a quad-core 1066MHz Intel EP80579 processor, supporting multi-threaded operations and high-speed data processing. It can handle complex control algorithms and large volumes of data, enabling real-time control.

- Multiple Redundancy Modes: Supports Triple Modular Redundancy (TMR), simplex, and dual redundancy modes to enhance fault tolerance and ensure continuous operation even in the event of failures.

- Rich Interfaces: Features two Hall effect pulse inputs, two analog inputs, and four digital input/output interfaces, enabling connection to various sensors and actuators.

- Strong Communication Capability: Supports multiple standard communication protocols for seamless integration with other devices and systems. It can communicate with host computers or other control devices via interfaces such as Ethernet to achieve data monitoring, control, and recording.

- Real-time Data Transmission: Leveraging EFA (Embedded Field Agent) technology and the QNX Neutrino operating system, it can transmit data in real time to connected controllers.

Technical Parameters

- Processor: 1066MHz Intel EP80579 quad-core processor.

- Storage: Built-in large-capacity storage supports storage and retrieval of system data and programs.

- I/O: Two Hall effect pulse inputs, two analog inputs, four digital input/outputs.

- Power Supply: Typically 220V voltage input.

- Frequency Output: 50kHz.

- Operating Temperature: -40°C to 70°C.

- Dimensions: 110mm×290mm.

Working Principle

- Data Processing: Processes collected data through a high-speed processor and multi-threaded operations. Utilizing the advantages of the QNX Neutrino OS ensures efficient and stable system operation for real-time control.

- Signal Acquisition and Control: Acquires sensor signals through various input interfaces—Hall effect pulse inputs for pulse signals and analog inputs for continuous analog signals. After internal processing, it controls actuators via digital input/output interfaces.

- Communication Principle: Parses and encapsulates data through supported communication protocols to enable data exchange with other devices and systems, ensuring reliable data transmission across different devices.

Common Faults and Solutions

Communication Faults

- Symptoms: Failure to communicate with other devices, such as interrupted data transmission or error messages.

- Possible Causes: Poor communication cable connections, incorrect communication parameter settings, or damaged communication interfaces.

- Solutions: Check if communication cables are properly connected and undamaged; re-plug or replace cables. Verify that communication parameters match those of other devices and reconfigure if Inconsistency. If a damaged interface is suspected, contact professionals for repair or module replacement.

Power Supply Faults

- Symptoms: No power indication on the module, unable to operate normally.

- Possible Causes: External power supply failure or damaged module power circuitry.

- Solutions: Check if the external power supply is normal and within the specified voltage range. If the external power supply is normal, the module's power circuit may be faulty, requiring professional maintenance.

Abnormal Data Processing

- Symptoms: Erroneous data processing results, data loss, etc.

- Possible Causes: Processor failure, memory issues, or software program errors.

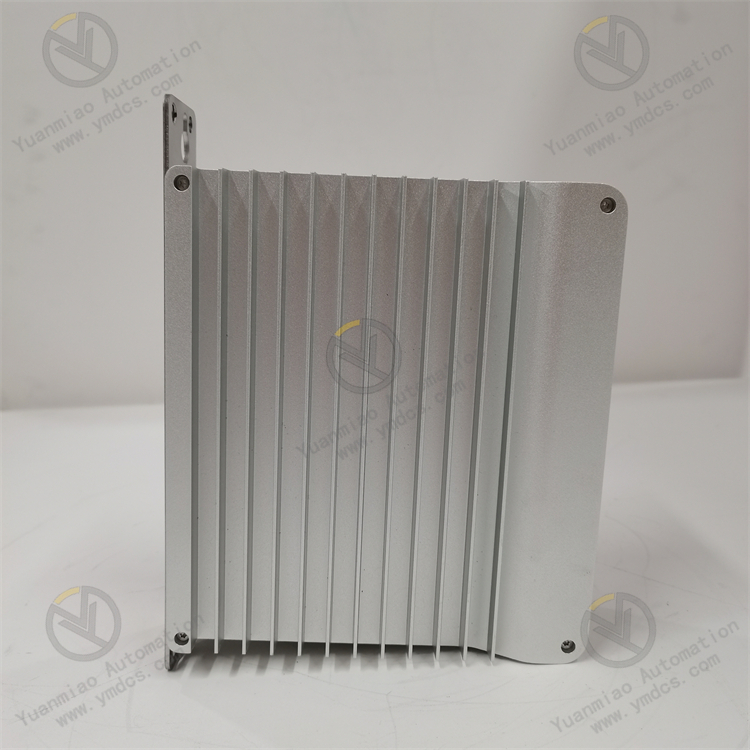

- Solutions: Ensure proper processor cooling to avoid overheating. Try restarting the module to restore normal operation. If the issue persists, it may be a software problem—contact technicians for debugging or upgrades. If memory failure is suspected, professional testing and replacement are required.

Operation Guide

- Installation: Directly mount the UCSC device on the installation base, leaving at least 4 inches of air clearance above and below the UCSC to ensure proper heat dissipation.

- Wiring: Correctly connect all input/output cables as per the manual, ensuring secure connections to avoid signal transmission issues due to looseness.

- Parameter Configuration: Use corresponding configuration software to set communication parameters, I/O parameters, etc., according to actual application requirements, ensuring normal communication and coordination with other devices.

- Monitoring and Maintenance: Use the module's LED indicators and related monitoring software to real-time monitor its operational status. Take timely corrective actions if anomalies are detected. Regularly clean and inspect the module to maintain optimal performance.