Description

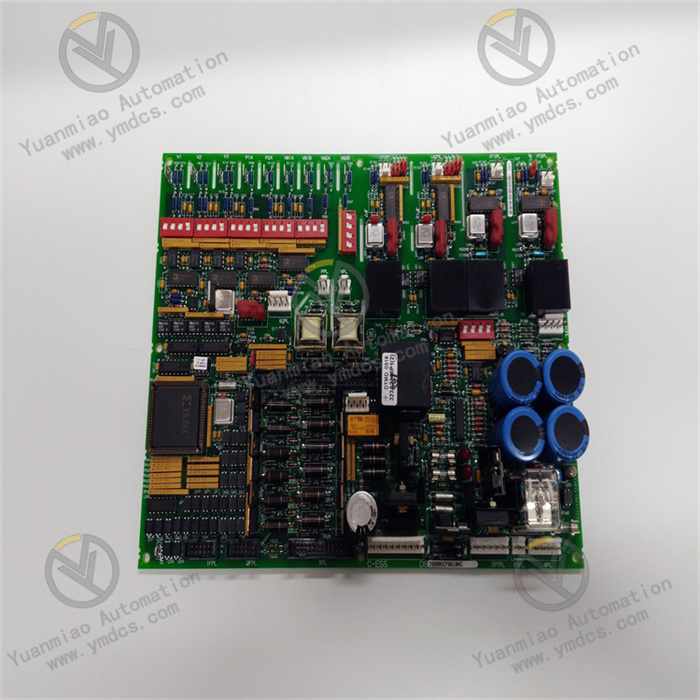

TRICONEX 8310N2

I. Overview

II. Technical Parameters

Processing capability: Equipped with a high-performance 32-bit processor, it has a fast computing speed and can efficiently process complex safety control logic and a large amount of real-time data. It supports multiple programming languages such as ladder diagram, Function Block Diagram (FBD), and Structured Text (ST), facilitating engineers to develop and debug programs according to actual needs.

Communication capability: Supports mainstream industrial communication protocols such as Modbus TCP/IP and EtherNet/IP, enabling high-speed data interaction with upper monitoring systems, HMI, and other intelligent devices. The communication interface adopts an optoelectronic isolation design, which has strong anti-electromagnetic interference ability, ensuring communication stability in complex industrial environments.

Safety certification: Certified by SIL3 (Safety Integrity Level 3), compliant with international safety standards such as IEC 61508 and IEC 61511. Its safety performance reaches a high industry standard, meeting the strict safety requirements of high-risk industrial scenarios.

III. Functional Features

High-speed safety interlock response: It has an extremely short response time to input signals, can identify abnormal states within milliseconds, and quickly output control commands according to preset safety logic. In emergency situations, such as detecting dangerous conditions like overpressure and overtemperature, it can instantly trigger safety actions such as emergency shutdown and cutting off energy supply, minimizing accident losses.

Online configuration and maintenance: Supports online programming, parameter modification, and program download without interrupting system operation, reducing production downtime caused by maintenance. Engineers can remotely configure and monitor the module through dedicated software, improving the convenience and efficiency of system maintenance.

IV. Common Faults and Solutions

Causes of failure: Poor contact or damage of communication cables; incorrect setting of network parameters such as IP address and subnet mask; hardware failure of the communication interface.

Solutions: Check the connection of communication cables, re-plug the connectors or replace with new cables; check and reconfigure network parameters to ensure they are in the same network segment as the upper system and the parameters match; if the interface hardware is faulty, replace the communication interface module or contact professional technical personnel for maintenance.

Loss of input signal

Causes of failure: Open circuit or short circuit of the input line; abnormal power supply of the sensor leading to no signal output; damage of the input channel.

Solutions: Use a multimeter to detect the on-off and voltage of the input line, and repair the broken or short-circuited points; check the sensor power supply to ensure normal power supply, and replace the faulty sensor; test by replacing with a normal module, and if it is determined that the input channel is damaged, replace the module.

Causes of failure: Short circuit of the output line causes the module to start the protection mechanism; failure of the actuator (such as relay, solenoid valve); damage of the output channel.

Solutions: Check the output line to eliminate the short-circuit fault and restore the output function of the module; detect the working status of the actuator and replace the faulty actuator; if the output channel is damaged, replace the module or repair the corresponding parts.

Abnormal flashing of the module running indicator

Causes of failure: Unstable power supply voltage or beyond the normal range; excessive internal temperature of the module; program operation error or memory failure.

Solutions: Detect the power supply voltage to ensure it is stable at 24V DC; check the heat dissipation of the module, clean the dust in the heat dissipation holes, and improve ventilation conditions; read the fault information through programming software, re-download the program or repair the memory fault, and if it is a hardware problem, contact the manufacturer to replace the module.