Description

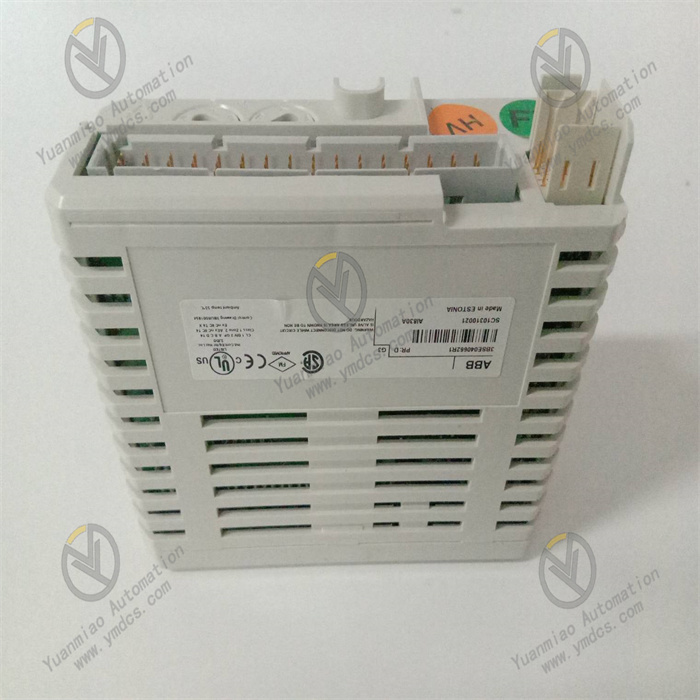

GE WES5302-111

I. Product Overview

II. Functional Features

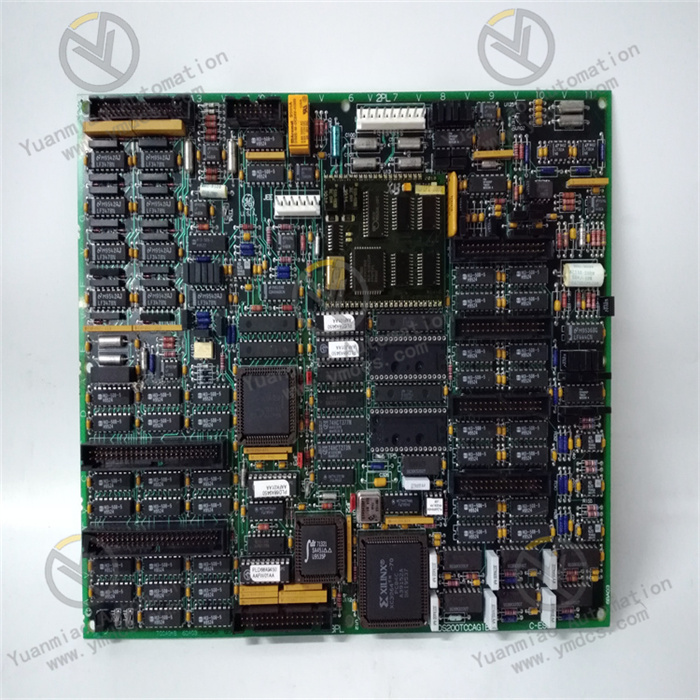

High-speed computing capability: Equipped with a high-performance industrial-grade processor, it has strong computing performance and can quickly process a large amount of data from on-site equipment. Whether it is dense sensor data on the production line or multi-source information in complex process flows, it can perform computing and analysis in a timely and accurate manner. Taking the automated production line of automobile manufacturing as an example, it can quickly process data such as part assembly positions and equipment operating status fed back by sensors at each workstation, ensuring the high-speed and stable operation of the production line and avoiding production stagnation or errors caused by untimely data processing.

Real-time monitoring and response: It supports real-time data collection and monitoring functions, and tracks key parameters in the industrial process in real time. Once abnormal parameters or equipment failures are detected, it can respond quickly, trigger an alarm mechanism through preset logic, and adjust control strategies in a timely manner. For example, in chemical production, the temperature, pressure and other parameters of the reaction kettle are monitored in real time. When the temperature exceeds the safety threshold, the module immediately alarms and starts the cooling system to prevent danger.

(2) Flexible and Diverse Communication Capabilities

Rich communication protocol support: It is fully compatible with various mainstream industrial communication protocols such as Modbus TCP/IP, Profibus DP, and Profinet, and can easily communicate and connect with devices and systems of different brands and types, breaking down communication barriers and realizing the interconnection of industrial networks. In a smart factory composed of equipment from multiple manufacturers, data interaction can be carried out with corresponding equipment through the Modbus protocol, and communication with industrial Ethernet equipment can be realized through the Profinet protocol to ensure the smooth flow of information in the factory network.

Multiple communication interface configurations: It is equipped with rich communication interfaces such as Ethernet, RS485, and serial ports. The Ethernet interface provides a high-speed data transmission rate, meeting the communication needs of large data volume and high real-time performance, and is suitable for connecting upper computers, cloud platforms and other devices to realize remote monitoring and management; the RS485 interface, with its good anti-interference and multi-node connection capabilities, is often used in industrial sites to connect various sensors and instruments to build a stable industrial data collection network; the serial port provides convenience for the connection and communication of specific devices, enhancing the adaptability of the module in different industrial scenarios.

Rich communication protocol support: It is fully compatible with various mainstream industrial communication protocols such as Modbus TCP/IP, Profibus DP, and Profinet, and can easily communicate and connect with devices and systems of different brands and types, breaking down communication barriers and realizing the interconnection of industrial networks. In a smart factory composed of equipment from multiple manufacturers, data interaction can be carried out with corresponding equipment through the Modbus protocol, and communication with industrial Ethernet equipment can be realized through the Profinet protocol to ensure the smooth flow of information in the factory network.

Multiple communication interface configurations: It is equipped with rich communication interfaces such as Ethernet, RS485, and serial ports. The Ethernet interface provides a high-speed data transmission rate, meeting the communication needs of large data volume and high real-time performance, and is suitable for connecting upper computers, cloud platforms and other devices to realize remote monitoring and management; the RS485 interface, with its good anti-interference and multi-node connection capabilities, is often used in industrial sites to connect various sensors and instruments to build a stable industrial data collection network; the serial port provides convenience for the connection and communication of specific devices, enhancing the adaptability of the module in different industrial scenarios.

(3) Reliable System Stability

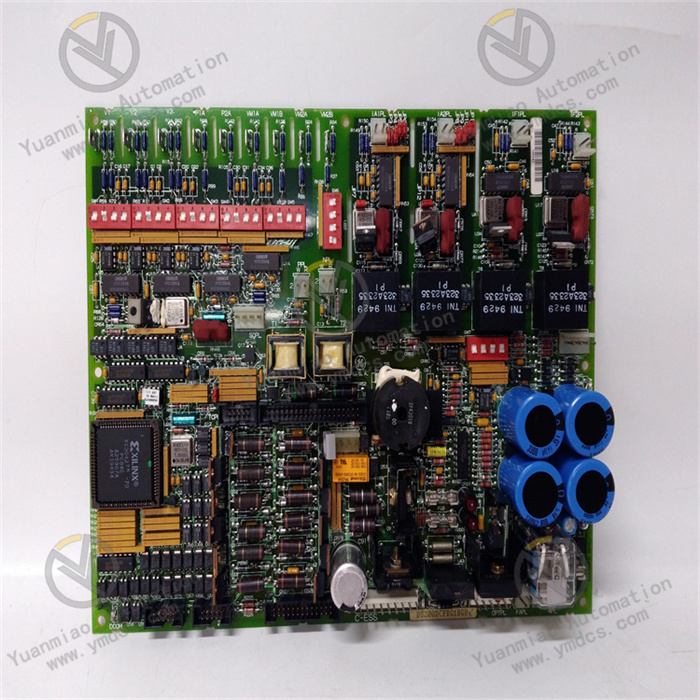

High-reliability hardware design: It adopts industrial-grade components and advanced circuit design to ensure the stable operation of the module in complex industrial environments at the hardware level. In terms of electrical performance, it has excellent anti-electromagnetic interference capability, effectively resisting electromagnetic interference generated by various electrical equipment in industrial sites, and avoiding data transmission errors or equipment misoperation. The power management system has been optimized to adapt to a wide range of input voltage fluctuations, ensuring that the module can still work normally when the power supply is unstable. In industrial scenarios with complex electromagnetic environments and large power supply fluctuations such as metallurgy and mining, GE WES5302-111 can operate stably, ensuring the continuity of the production process.

Fault diagnosis and self-repair function: It has a built-in perfect fault diagnosis mechanism to monitor its own operating status in real time. Once a fault is detected, it immediately conducts fault location and analysis, and informs the user through indicator lights, alarm signals, etc. In some fault cases, the module has a certain self-repair capability, such as automatically restarting relevant functional modules and re-establishing communication connections, to minimize system downtime caused by faults and improve the reliability and stability of industrial production.

High-reliability hardware design: It adopts industrial-grade components and advanced circuit design to ensure the stable operation of the module in complex industrial environments at the hardware level. In terms of electrical performance, it has excellent anti-electromagnetic interference capability, effectively resisting electromagnetic interference generated by various electrical equipment in industrial sites, and avoiding data transmission errors or equipment misoperation. The power management system has been optimized to adapt to a wide range of input voltage fluctuations, ensuring that the module can still work normally when the power supply is unstable. In industrial scenarios with complex electromagnetic environments and large power supply fluctuations such as metallurgy and mining, GE WES5302-111 can operate stably, ensuring the continuity of the production process.

Fault diagnosis and self-repair function: It has a built-in perfect fault diagnosis mechanism to monitor its own operating status in real time. Once a fault is detected, it immediately conducts fault location and analysis, and informs the user through indicator lights, alarm signals, etc. In some fault cases, the module has a certain self-repair capability, such as automatically restarting relevant functional modules and re-establishing communication connections, to minimize system downtime caused by faults and improve the reliability and stability of industrial production.

(4) Unique Functions

Multiple digital input channels: It has multiple digital input channels, which can connect multiple switches, sensors or other digital signal sources to realize comprehensive monitoring of various equipment and systems. At the same time, it supports different types of digital signal inputs, such as discrete signals or frequency signals, to meet the needs of different application scenarios.

High-speed counting function: It supports high-speed counting function, can read high-frequency signals, such as encoder signals, and provides high-precision counting measurement, which is crucial for application scenarios requiring precise control.

Safety protection function: It has safety functions to protect the reliability and stability of input signals and prevent misoperation or faults. The online diagnosis and monitoring function can monitor the status of input signals in real time, detect potential faults or abnormal situations, and ensure the stable operation of the system.

Multiple digital input channels: It has multiple digital input channels, which can connect multiple switches, sensors or other digital signal sources to realize comprehensive monitoring of various equipment and systems. At the same time, it supports different types of digital signal inputs, such as discrete signals or frequency signals, to meet the needs of different application scenarios.

High-speed counting function: It supports high-speed counting function, can read high-frequency signals, such as encoder signals, and provides high-precision counting measurement, which is crucial for application scenarios requiring precise control.

Safety protection function: It has safety functions to protect the reliability and stability of input signals and prevent misoperation or faults. The online diagnosis and monitoring function can monitor the status of input signals in real time, detect potential faults or abnormal situations, and ensure the stable operation of the system.

III. Technical Parameters

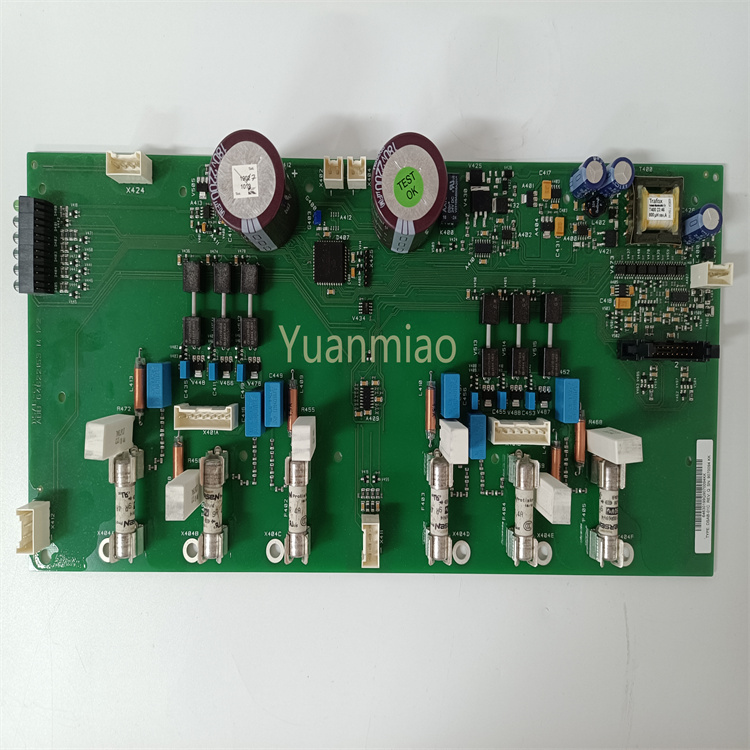

Input voltage: 24VDC, which adapts to the power supply requirements of specific industrial scenarios, can be stably connected to relevant power supply systems, and ensures the normal operation of the module.

Output voltage: 24VDC, which provides a stable and accurate working voltage for connected load devices, meets the specific requirements of various sensors, actuators, etc. for the power supply voltage, and ensures the normal operation of the equipment and the accurate transmission of signals.

Electrical characteristics of communication interfaces: The Ethernet interface supports high-speed data transmission, and the specific rate may be adaptively adjusted according to the connected equipment to ensure efficient data interaction; the RS485 interface uses differential signal transmission, has good anti-interference performance, and the transmission distance can reach a certain range (such as about 1200 meters related to cable quality and environment), meeting the needs of long-distance communication in industrial sites; the serial communication rate can be flexibly configured within a certain range to adapt to the communication rate requirements of different devices.

(2) Physical Parameters

Dimensions: 165mm x 100mm x 50mm, with a compact design, which can be easily installed in electrical control cabinets and equipment enclosures with limited space, saving valuable installation space, facilitating system integration and wiring, and is especially suitable for industrial automation equipment with strict space requirements.

Weight: 1.2kg, light in weight, convenient for transportation and installation, not only reducing the load requirements on structures such as mounting brackets, reducing installation difficulty, but also helping to improve the stability and reliability of the entire system, and facilitating the handling and installation of equipment in different scenarios.

Installation methods: It supports multiple installation methods, commonly including rail mounting and panel mounting. Rail mounting conforms to industrial standards, is convenient and fast, and can quickly fix the module on the standard rail of the industrial control cabinet, facilitating maintenance and replacement; panel mounting is suitable for scenarios with high requirements on installation position and protection. By installing the module on the equipment panel, it is convenient for operators to debug and monitor, and better protects the module from the external environment.

Dimensions: 165mm x 100mm x 50mm, with a compact design, which can be easily installed in electrical control cabinets and equipment enclosures with limited space, saving valuable installation space, facilitating system integration and wiring, and is especially suitable for industrial automation equipment with strict space requirements.

Weight: 1.2kg, light in weight, convenient for transportation and installation, not only reducing the load requirements on structures such as mounting brackets, reducing installation difficulty, but also helping to improve the stability and reliability of the entire system, and facilitating the handling and installation of equipment in different scenarios.

Installation methods: It supports multiple installation methods, commonly including rail mounting and panel mounting. Rail mounting conforms to industrial standards, is convenient and fast, and can quickly fix the module on the standard rail of the industrial control cabinet, facilitating maintenance and replacement; panel mounting is suitable for scenarios with high requirements on installation position and protection. By installing the module on the equipment panel, it is convenient for operators to debug and monitor, and better protects the module from the external environment.

(3) Environmental Parameters

Operating temperature range: -20°C to +70°C, which can adapt to a wide range of temperature environments. Whether it is industrial facilities in cold regions or production workshops in hot environments, it can ensure the normal and stable operation of the module, ensuring that the industrial automation system is not affected by the ambient temperature and realizes continuous operation.

Humidity adaptation: It can work normally in an environment with a relative humidity of 0% to 95% (non-condensing). The excellent moisture-proof design enables it to effectively cope with humid environments, such as factory workshops in rainy southern regions and underground distribution rooms, avoiding electrical short circuits, corrosion and other faults caused by humidity problems, prolonging the service life of the module, and ensuring the long-term stable operation of the system.

Protection level: It has a certain protection capability. Although the specific protection level is not clearly specified, from the perspective of design and application scenarios, it can resist interference from external factors such as dust to a certain extent, and is suitable for installation in environments with relatively good protection such as control cabinets. If equipped with an additional protective shell, the protection capability can be further improved to adapt to harsher industrial environments.

Operating temperature range: -20°C to +70°C, which can adapt to a wide range of temperature environments. Whether it is industrial facilities in cold regions or production workshops in hot environments, it can ensure the normal and stable operation of the module, ensuring that the industrial automation system is not affected by the ambient temperature and realizes continuous operation.

Humidity adaptation: It can work normally in an environment with a relative humidity of 0% to 95% (non-condensing). The excellent moisture-proof design enables it to effectively cope with humid environments, such as factory workshops in rainy southern regions and underground distribution rooms, avoiding electrical short circuits, corrosion and other faults caused by humidity problems, prolonging the service life of the module, and ensuring the long-term stable operation of the system.

Protection level: It has a certain protection capability. Although the specific protection level is not clearly specified, from the perspective of design and application scenarios, it can resist interference from external factors such as dust to a certain extent, and is suitable for installation in environments with relatively good protection such as control cabinets. If equipped with an additional protective shell, the protection capability can be further improved to adapt to harsher industrial environments.

IV. Application Scenarios

Production line automation: It plays a core control role in the production lines of various manufacturing industries such as automobile manufacturing, electronics manufacturing, and food processing. It connects various equipment on the production line such as robots, automated assembly equipment, and material conveying systems, and realizes the automated operation and precise control of the production line by transmitting equipment operating status information and control commands in real time. In the automobile manufacturing workshop, when auto parts are transported to the assembly station, the sensor transmits the position signal to GE WES5302-111, and the module controls the robot to perform precise assembly according to the preset program, while monitoring parameters such as torque and position during the assembly process to ensure assembly quality and improve production efficiency and product quality.

Energy management: Energy consumption in manufacturing factories is huge, and it can be used to build an energy management system. It connects various energy monitoring equipment such as electricity meters, water meters, and gas meters, collects energy consumption data in real time, and conducts analysis and processing. Through linkage control with production equipment, the optimal distribution and utilization of energy are realized. According to the production plan and equipment operating status, dynamically adjust the power output of the equipment to reduce energy consumption on the premise of ensuring production, achieve the goal of energy conservation and emission reduction, and improve the economic benefits and sustainable development capabilities of the enterprise.

(2) Energy Industry

Power system monitoring: In power system facilities such as power plants and substations, it is used to monitor the operating parameters of power equipment in real time, such as the voltage, current, frequency of generators, and the oil temperature and winding temperature of transformers. By analyzing these data, potential faults of equipment can be found in time, and maintenance measures can be taken in advance to ensure the safe and stable operation of the power system. At the same time, it communicates with the power dispatching system to realize the reasonable distribution and dispatching of electricity, ensuring the reliability and stability of power supply and meeting the electricity needs of social production and life.

Oil and gas transmission: In the process of oil and gas exploitation and transmission, parameters such as pipeline pressure, flow rate, and temperature are monitored and controlled in real time. It connects various sensors and actuators distributed along the pipeline, collects data in real time, and controls equipment operations such as valve opening and closing, pump start and stop according to preset logic. When the pipeline pressure rises abnormally, the module immediately controls the safety valve to open for pressure relief, and starts the backup pump to adjust the flow rate, ensuring the safety and stability of the oil and gas transmission process and preventing accidents such as leaks.

Power system monitoring: In power system facilities such as power plants and substations, it is used to monitor the operating parameters of power equipment in real time, such as the voltage, current, frequency of generators, and the oil temperature and winding temperature of transformers. By analyzing these data, potential faults of equipment can be found in time, and maintenance measures can be taken in advance to ensure the safe and stable operation of the power system. At the same time, it communicates with the power dispatching system to realize the reasonable distribution and dispatching of electricity, ensuring the reliability and stability of power supply and meeting the electricity needs of social production and life.

Oil and gas transmission: In the process of oil and gas exploitation and transmission, parameters such as pipeline pressure, flow rate, and temperature are monitored and controlled in real time. It connects various sensors and actuators distributed along the pipeline, collects data in real time, and controls equipment operations such as valve opening and closing, pump start and stop according to preset logic. When the pipeline pressure rises abnormally, the module immediately controls the safety valve to open for pressure relief, and starts the backup pump to adjust the flow rate, ensuring the safety and stability of the oil and gas transmission process and preventing accidents such as leaks.

(3) Chemical Industry

Process control: In chemical production processes such as petrochemicals and pharmaceuticals, precise control of reaction conditions is crucial. It connects sensors and actuators on various chemical equipment such as reactors, distillation towers, and centrifuges, monitors process parameters such as temperature, pressure, liquid level, and flow rate in real time, and precisely adjusts the operating status of the equipment according to preset process formulas and control strategies. In pharmaceutical production, the temperature and pH value in the reactor are strictly controlled to ensure the stability and consistency of drug quality and guarantee the safety and effectiveness of drug production.

Automated management: The production process of chemical enterprises is complex, involving many equipment and links. It can be used as a core component of the automated management system to realize centralized monitoring and management of the entire production process. It aggregates data from various production links to the central control system, and managers can understand the overall production situation in real time through the monitoring interface, find problems in time and make decisions. Through integration with the Enterprise Resource Planning (ERP) system, it realizes the collaborative operation of production planning, material management, quality management and other links, improving the production efficiency and management level of the enterprise.

Process control: In chemical production processes such as petrochemicals and pharmaceuticals, precise control of reaction conditions is crucial. It connects sensors and actuators on various chemical equipment such as reactors, distillation towers, and centrifuges, monitors process parameters such as temperature, pressure, liquid level, and flow rate in real time, and precisely adjusts the operating status of the equipment according to preset process formulas and control strategies. In pharmaceutical production, the temperature and pH value in the reactor are strictly controlled to ensure the stability and consistency of drug quality and guarantee the safety and effectiveness of drug production.

Automated management: The production process of chemical enterprises is complex, involving many equipment and links. It can be used as a core component of the automated management system to realize centralized monitoring and management of the entire production process. It aggregates data from various production links to the central control system, and managers can understand the overall production situation in real time through the monitoring interface, find problems in time and make decisions. Through integration with the Enterprise Resource Planning (ERP) system, it realizes the collaborative operation of production planning, material management, quality management and other links, improving the production efficiency and management level of the enterprise.