Description

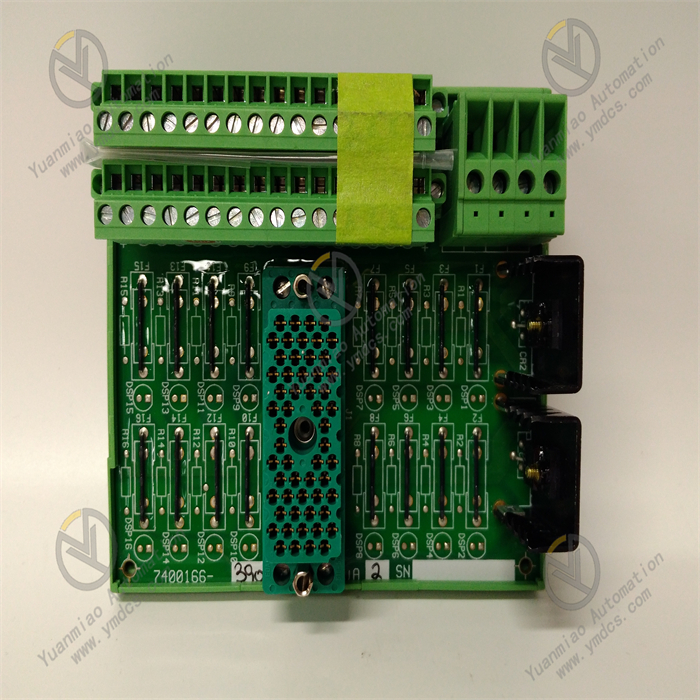

GE IC695CPU315-CD

I. Overview

II. Technical Parameters

Processor Performance: Equipped with a high-performance 32-bit multi-core processor with a main frequency of up to 1GHz, it has excellent data processing capability and multi-task parallel processing capability. It can quickly execute complex control algorithms with fast response speed, ensuring timely handling of various events in the industrial production process.

Power Requirements: The working power is supplied by the backplane of the RX7i system, with an input voltage of 5V DC and a typical working current of 800mA. The power consumption is moderate, which will not cause excessive pressure on the system power supply, ensuring stable power supply for the system.

Communication Interfaces: Equipped with 2 10/100/1000Mbps Gigabit Ethernet interfaces, supporting protocols such as TCP/IP and Modbus/TCP to realize high-speed network communication; 1 USB 2.0 interface for program downloading, data backup, and debugging; and 1 RS-232 serial interface for convenient communication with traditional devices.

Dimensions: Adopting a compact design with a width of 64mm, a height of 110mm, and a depth of 125mm, it can be conveniently installed in the RX7i series rack, saving installation space.

III. Functional Features

Rich Communication Functions: Through the Gigabit Ethernet interface, it can realize high-speed data interaction with upper computers, HMIs, and other controllers, and supports network redundancy to improve communication reliability. At the same time, multiple communication interfaces and protocol support enable it to seamlessly connect with industrial equipment of different brands and types, enhancing the compatibility and expandability of the system.

Flexible Programming and Development: Supports multiple international standard programming languages, including Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Sequential Function Chart (SFC), etc. Engineers can choose appropriate programming languages for program development according to their habits and needs. Through GE's Proficy Machine Edition programming software, functions such as program writing, debugging, and downloading can be realized, with high development efficiency.

Data Security and Protection: Supports user permission management, which can set different operation permissions according to different user roles to prevent unauthorized personnel from modifying programs and parameters, ensuring system security. At the same time, it has a program encryption function to protect users' intellectual property rights and prevent programs from being illegally copied and tampered with.

IV. Common Faults and Solutions

Possible Causes: Power failure, such as unstable input voltage, loose power wiring; memory failure, such as poor contact or damage of memory modules; program errors, such as serious logical errors in the program leading to failure to load; internal circuit failure of the CPU module.

Solutions: Check whether the power input is stable at 5V DC, check whether the power wiring is firm, and replace the power module if necessary. Re-plug the memory module to ensure good contact. If the problem persists, replace the memory module for testing. Check whether the program has errors, debug and correct it through programming software, and re-download the correct program. If the above methods are ineffective, it may be an internal fault of the CPU module, and the module needs to be replaced.

Possible Causes: Physical damage to the Ethernet interface or serial interface; faults in communication cables, such as broken network cables, poor contact of USB cables; incorrect communication parameter settings, such as IP address conflict, protocol mismatch; faults in network devices, such as switch failure.

Solutions: Check whether the communication interface is physically damaged, and replace the corresponding interface components if damaged. Replace the communication cable to ensure firm and intact connection. Check the communication parameters to ensure that the IP address, subnet mask, gateway, etc. are set correctly, and the protocol matches the communication device. Check whether network devices such as switches are working normally, and test by replacing ports or devices.

Possible Causes: Logical errors or loopholes in the program; variable address conflict or incorrect setting; abnormal external input signals leading to confusion in program execution; insufficient memory leading to program operation interruption.

Solutions: Use programming software to comprehensively check and debug the program, find logical errors and variable setting problems through the online monitoring function and correct them. Check whether the external input signals are normal to eliminate the impact of sensor faults or signal interference. Optimize the program by deleting redundant data and codes to free up memory space. If the memory is still insufficient, consider upgrading the memory.

Possible Causes: Poor contact between the I/O module and the CPU module; power failure of the I/O module; incorrect address setting of the I/O module; failure of the I/O module itself.

Solutions: Reinstall the I/O module to ensure good contact with the rack backplane. Check whether the power input of the I/O module is normal to eliminate power failure. Check the address setting of the I/O module to ensure it is consistent with the system configuration and has no address conflict. Replace with a spare I/O module for testing. If the spare module is normal, it indicates that the original module is faulty and needs to be replaced.

Possible Causes: Poor heat dissipation of the CPU module, leading to excessive operating temperature; excessive fluctuation of power supply voltage; internal circuit failure of the module; serious errors such as infinite loops in the program.

Solutions: Clean the heat dissipation holes of the CPU module, ensure that the cooling fan works normally, and avoid excessive temperature. Check whether the power supply voltage is stable, and install a voltage stabilizing device if necessary. Check whether the program has errors such as infinite loops and correct them. If the above methods are ineffective, it may be an internal circuit failure of the module, and the CPU module needs to be replaced.