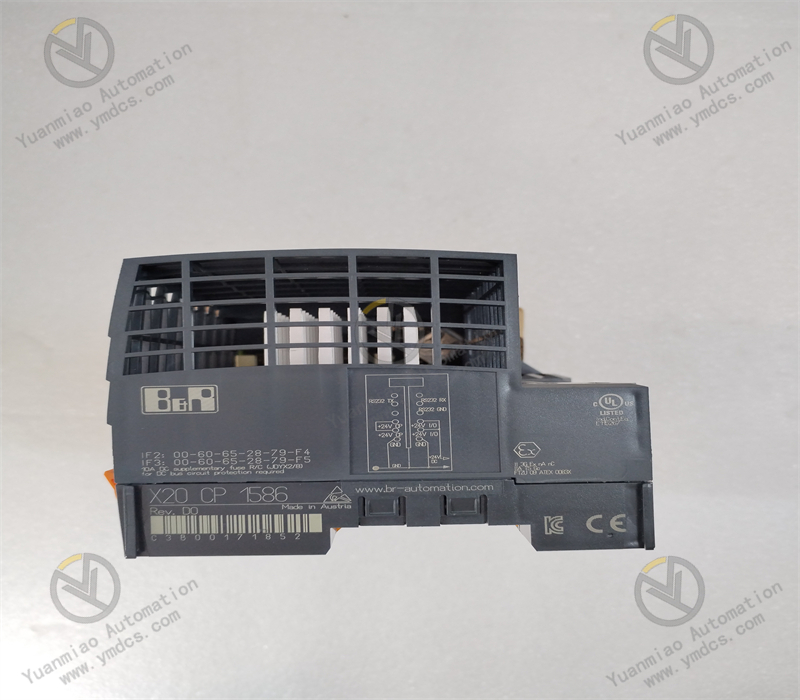

Description

Functional Features of B&R X20CP1586

I. High-Performance Processing Capability

Multi-Core Processor Architecture

- Equipped with an ARM Cortex-A9 dual-core processor running at up to 1 GHz, supporting multi-task parallel processing to quickly execute complex control logic, motion algorithms, and data operations.

- Built-in Floating-Point Unit (FPU) enhances mathematical calculation accuracy and efficiency, suitable for high-precision control scenarios (e.g., robotics, precision machinery).

High-Speed Data Processing

- Supports nanosecond-level timers and high-speed counters to respond in real time to fast input signals (e.g., encoder pulses, sensor triggers).

- Embedded Real-Time Operating System (RTOS) ensures deterministic and real-time control tasks, meeting industrial real-time control requirements.

II. Rich Communication Interfaces and Protocols

Standard Communication Interfaces

- 2× Ethernet ports: Support mainstream industrial communication protocols such as Ethernet POWERLINK (B&R's real-time industrial Ethernet), PROFINET, and EtherNet/IP, enabling high-speed data interaction between the controller and upper computers, sensors, and drives.

- 2× RS232/RS485 serial ports: Compatible with protocols like Modbus RTU and CANopen, suitable for traditional industrial devices.

- USB ports: Used for program downloading, data backup, or connecting external devices (e.g., keyboards, USB drives).

Distributed System Expansion

- Connects to distributed I/O modules (e.g., X20DI, X20AO) via the X20 bus (high-speed backplane bus), supporting hot-swapping for easy system expansion and maintenance.

- Can connect up to 254 modules, meeting the I/O point requirements of large-scale automation systems.

III. Modularity and Flexibility

X20 System Architecture Compatibility

- As the central processing unit (CPU) module of the X20 series, it seamlessly integrates with X20 series I/O modules, motion control modules, and safety modules to build customized control systems.

- Supports modular installation via rail mounting, saving control cabinet space and facilitating on-site deployment.

Multi-Language Programming and Development Tools

- Supports IEC 61131-3 standard programming languages: Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Sequential Function Chart (SFC), etc., adapting to different engineers' programming habits.

- Uses the B&R Automation Studio development platform, integrating project management, programming, debugging, and simulation functions, with support for code reuse and version control to enhance development efficiency.

IV. Motion Control and Expansion Capability

Built-in Motion Control Functions

- Supports multi-axis synchronization control (e.g., electronic cam, gear synchronization), with a maximum of 64 axes (requires matching motion control modules), suitable for scenarios requiring high-precision motion control such as robotics, printing machinery, and packaging equipment.

- Compatible with the B&R ACOPOS servo system, achieving real-time communication and control of servo drives via Ethernet POWERLINK.

Functional Expansion Module Support

- Connects to dedicated modules via the X20 bus for expanded functions, including:

- Safety control (e.g., X20SC safety module, compliant with ISO 13849 standards);

- Vision inspection (integrated machine vision algorithms or third-party vision systems);

- Internet of Things (IoT) interfaces (e.g., MQTT, OPC UA for data cloud integration and remote monitoring).

V. Industrial-Grade Reliability and Environmental Adaptability

High-Stability Design

- Operates in a wide temperature range of -25°C to +60°C, adapting to harsh industrial environments (e.g., high-temperature workshops, cold storage).

- Resistant to vibration and shock (compliant with IEC 60068-2-6/27 standards), meeting mechanical stress requirements in industrial fields.

- Power redundancy and reverse polarity protection design ensure hardware safety during power fluctuations or wiring errors.

Industrial Protection Grade

- The controller Ontology (rail-mounted) has an IP20 protection rating, and higher protection requirements can be met with a control cabinet.

- Supports long-term stable operation with an average mean time between failures (MTBF) of over 100,000 hours, suitable for 24/7 continuous production scenarios.

VI. Data Management and Diagnostic Functions

Data Storage and Logging

- Built-in non-volatile memory (e.g., flash) supports power-off preservation of programs and data.

- Records system logs, fault alarms, and operational data for problem tracing and process optimization.

Online Diagnosis and Debugging

- Enables online monitoring via Automation Studio: real-time viewing of variable statuses, parameter modification, forced I/O outputs, etc.

- Supports remote debugging (via Ethernet), reducing on-site maintenance costs and improving fault response speed.

Technical Parameters

- Processor: Intel Atom E680T, 1.6 GHz clock frequency.

- Memory:

- 512 MB DDR2 SDRAM.

- 1 MB SRAM.

- Expandable CompactFlash storage (512 MB to 4 GB).

- Communication Interfaces:

- 1× RS232 port (connected via 12-pin terminal block X20TB12), max. distance 900 m, max. transmission rate 115.2 kbit/s.

- 1× Ethernet port (RJ45 shielded), supports 10/100/1000 Mbit/s, half-duplex, full-duplex, auto-negotiation, and auto-MDI/MDIX.

- 1× POWERLINK (V1/V2) Type 4 port (RJ45 shielded), 100 Mbit/s transmission rate.

- 2× USB ports (Type A, USB 1.1/2.0), max. output current 0.5 A.

- 1× X2X Link port (master station). Electrical isolation between Ethernet, POWERLINK, X2X, and other interfaces/PLC.

- Input Voltage: 24 VDC (allowing -15% to +20% variation).

- Input Current: Max. 1.5 A.

- Power Consumption:

- 9.7 W without interface modules and USB connections.

- 1.42 W for X2X Link power.

- 0.6 W for internal I/O.

- Dimensions: 150 mm (W) × 99 mm (H) × 85 mm (D).

- Weight: 400 g.

- Operating Temperature:

- Horizontal installation: -25°C to 60°C.

- Vertical installation: -25°C to 50°C.

- Storage Temperature: -40°C to 85°C.

- Relative Humidity: 5% to 95% (non-condensing during operation and storage).

- Protection Rating: IP20.

- Electrical Isolation: Isolation between Ethernet (IF2), POWERLINK (IF3), and X2X (IF6), as well as from other interfaces and the PLC.

- Real-Time Clock: Non-volatile, 1 s resolution, accuracy of -10 to 10 ppm at 25°C.

- FPU: Supported.

- L1 Cache: 24 KB (data/code), 32 KB (program code).

- L2 Cache: 512 KB.

- Shortest Task Class Cycle Time: 100 µs.

- Typical Instruction Cycle Time: 0.0027 µs.

- Battery: Lithium battery, minimum 2 years of use at 23°C, monitored via LED status indicators and software.

Application Scenarios

- High-End Equipment Manufacturing: Robotics, CNC machine tools, semiconductor equipment.

- Process Industry: Automation control for chemical, pharmaceutical, and food/beverage production lines.

- New Energy Sector: Motion control and process optimization for photovoltaic equipment and lithium battery production lines.

- Smart Factories: As an edge controller, connecting to industrial internet for device networking and data collection.