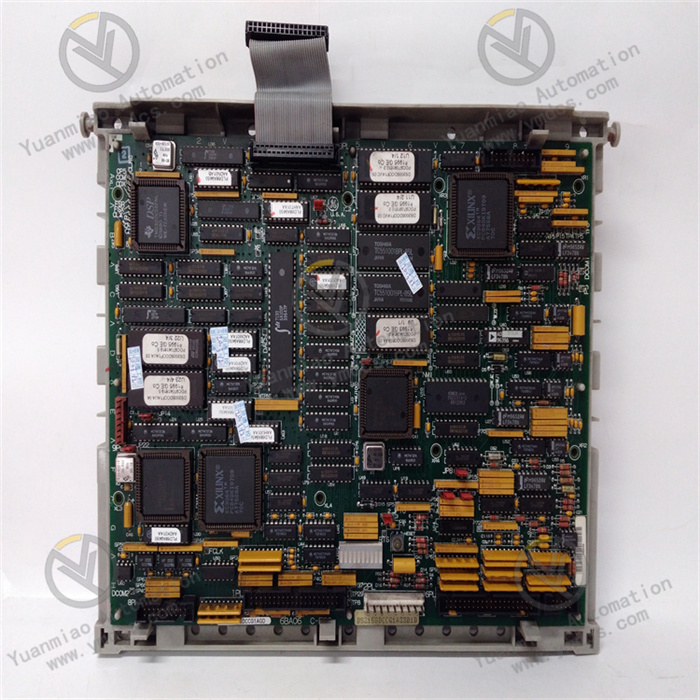

Description

Emerson A6500-CC 9199-00120 is a communication and framework interface module in the AMS 6500 ATG series, designed for mechanical health monitoring systems.

Electrical Parameters

- Input voltage: 100-240V AC

- Output voltage: 24V DC

- Maximum output current: 5A

- Power supply: AC 220V, frequency range 50Hz-60Hz

Dimensions and Weight

- Dimensions: 150mm x 100mm x 50mm

- Weight: 500g

Operating and Storage Temperatures

- Operating temperature: -10°C to +60°C

- Storage temperature: -40°C to +85°C

Functional Features

- Powerful Communication Capability

- Supports multiple communication protocols such as Modbus TCP/IP, Modbus RTU, and OPC UA, facilitating data communication and exchange with other devices and systems.

- Strong Data Processing Ability

- Enables high-speed sampling rates for rapid acquisition and conversion of digital signals.

- Adapts to voltage or level ranges of different digital signals and detects/records state changes (e.g., rising edges, falling edges, or edge triggers) of digital input signals to provide real-time status information to the system.

- Safety Protection Functions

- Provides multiple safety protections, including overcurrent protection, overload protection, overvoltage protection, and short-circuit protection, to safeguard the module and system from power-related issues.

- Hot-Swap Support

- Allows hot-swapping for easy maintenance and upgrades, enabling module replacement or upgrades without interrupting system operation.

Application Fields

- Industrial automation: Used for data acquisition, monitoring, and control to improve production efficiency and product quality.

- Intelligent building systems: Applicable to environmental monitoring, energy management, and other scenarios.

- Critical rotating machinery monitoring: Suitable for monitoring key factory equipment such as steam turbines, gas turbines, compressors, and hydroturbines.

Working Principles

- Data Acquisition and Conversion

- Utilizes high-speed sampling rates to collect and convert digital signals rapidly.

- Adapts to various digital signal voltage/level ranges and monitors state changes (e.g., edge triggers) of digital inputs to provide real-time status information.

- Parameter Reading and Output

- As a communication module, it reads parameters from all CSI A6500 ATG modules and outputs them via ModBus TCP/IP or ModBus RTU (serial).

- Also transmits data to third-party systems via OPC UA, enabling data sharing and interaction across systems.

- System Integration and Collaboration

- Works with other CSI A6500 ATG monitoring modules to form a complete equipment protection and monitoring system compliant with API 670 standards.

- Provides data interfaces (ModBus TCP/IP, ModBus RTU, or OPC UA) for local display devices and instrument readings in protection framework cabinets, allowing operators to obtain equipment status parameters in control systems for seamless integration.

General Operation Guide for Emerson A6500-CC 9199-00120

Installation

- Module Inspection: Before installation, verify no physical damage and ensure the model matches the required system configuration.

- Installation Location Selection: Choose a suitable location based on equipment layout and heat dissipation requirements. Ensure adequate space for cooling and maintenance, and avoid humid, high-temperature, or strong electromagnetic interference environments.

- Electrical Connections:

- Properly connect power lines, ensuring the input voltage is within 100-240V AC and frequency is 50-60Hz.

- Establish correct communication connections with other modules in the CSI A6500 ATG system, ensuring secure connections to prevent communication failures due to looseness.

Configuration

- Communication Protocol Setup:

- Set the module’s communication protocol (e.g., ModBus TCP/IP, ModBus RTU, OPC UA) via relevant software or configuration interfaces.

- Configure parameters such as IP address, port number, and slave address to ensure proper communication with external devices/systems.

- Functional Parameter Configuration:

- Adjust functional parameters (e.g., sampling rate, input signal type/range) based on the application scenario. For example, if connecting digital signal sensors, set appropriate input level ranges to match sensor outputs.

Operation and Monitoring

- Data Acquisition and Viewing: Once operational, the module collects data at the configured sampling rate. Operators can view equipment status parameters (e.g., digital signal changes, sensor measurements) via human-machine interfaces or monitoring software connected to the system.

- Equipment Status Monitoring:

- Monitor the module’s status indicators (e.g., power indicator should be constantly on; communication indicator should flash with activity).

- Check monitoring software for alarm messages or error prompts to identify and address issues promptly.

- Data Transmission and Sharing: The module transmits processed data to other systems/devices via the configured communication protocol. Ensure receiving devices can correctly parse the data for seamless sharing across the industrial automation system.

Maintenance and Servicing

- Regular Inspections: Periodically check for loose connections, physical damage, or overheating. Clean dust from the module’s surface to maintain proper heat dissipation.

- Software Updates: Update the module’s firmware or related software timely per Emerson’s recommendations to enhance performance, add features, and fix potential vulnerabilities.

- Fault Handling: For module failures, first refer to the user manual or technical documentation for preliminary troubleshooting (e.g., common issues like communication or power failures). Contact Emerson’s technical support or professional maintenance personnel for complex problems.