Description

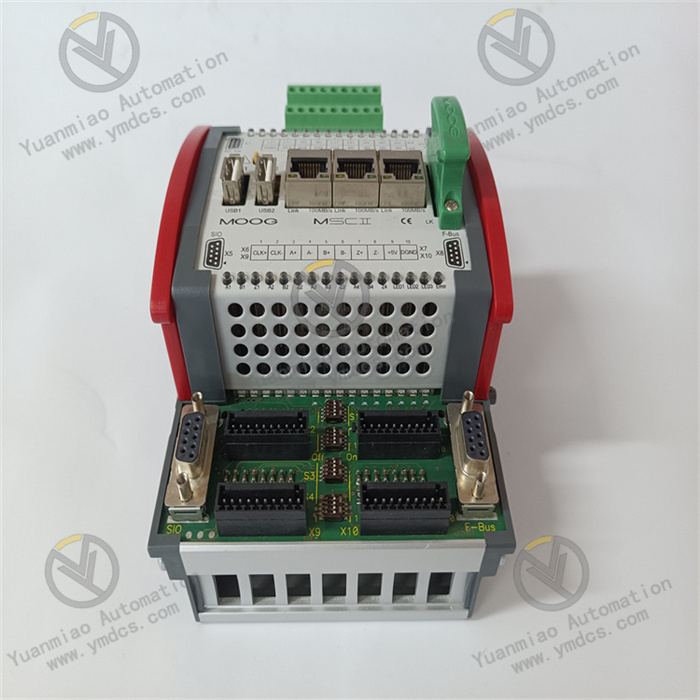

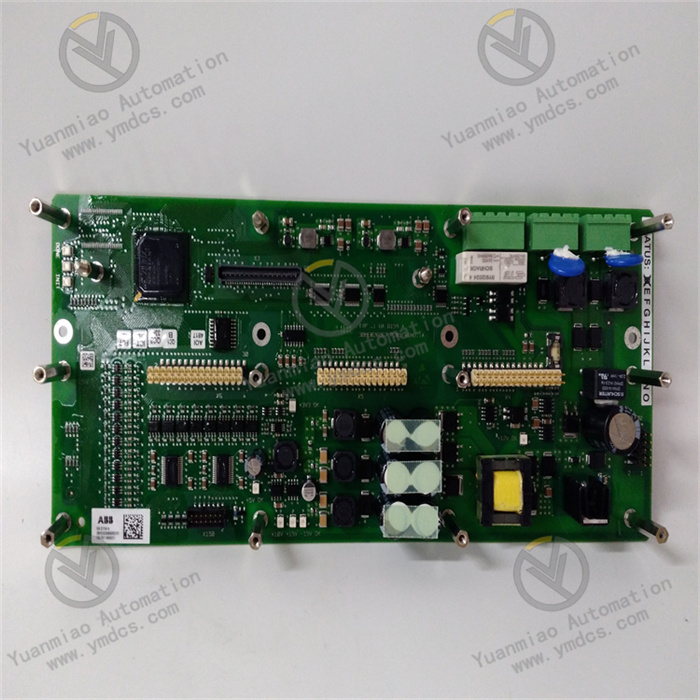

Functional Features High-precision monitoring: By adopting advanced sensor technology and signal processing algorithms, it can accurately monitor key parameters such as the vibration and displacement of rotating machinery, providing accurate data support for the condition assessment of equipment. Real-time data collection and analysis: It has the ability to collect data rapidly. It can collect various data during the operation of equipment in real time, and conduct real-time analysis to promptly detect potential faults of the equipment, enabling corresponding measures to be taken. Reliability design: Using high-quality electronic components and a sturdy shell design, it has good anti-interference ability and environmental adaptability. It can operate stably and reliably in harsh industrial environments, ensuring long-term trouble-free operation. Multiple output methods: It provides various output interfaces, such as analog output, digital output, etc. It can be easily integrated with other control systems or monitoring equipment to achieve data sharing and remote monitoring.

Technical Parameters Measurement range: The vibration measurement range is usually 0 - 500μm (peak-peak value), and the displacement measurement range is 0 - 25mm, etc. The specific measurement range may vary depending on different configurations. Accuracy: The vibration measurement accuracy can reach ±1%, and the displacement measurement accuracy can reach ±0.5%, meeting the measurement accuracy requirements of most industrial applications. Sampling frequency: The sampling frequency is generally 10kHz - 100kHz, which can be set according to actual needs to ensure that sufficient signal details are collected. Operating temperature range: -40°C - 85°C, adapting to various temperature conditions in industrial field environments.

Application Areas Power industry: Widely applied to the condition monitoring of large rotating mechanical equipment such as steam turbines and generators in power plants, promptly detecting problems such as abnormal vibrations of the equipment to ensure the safe and stable operation of power equipment. Petrochemical industry: Conduct vibration monitoring and fault diagnosis on key equipment such as compressors and pumps in refineries and chemical plants to avoid production interruptions and safety accidents caused by equipment failures. Metallurgical industry: Used for the condition monitoring of equipment such as blast furnace blowers and rolling mills in metallurgical production. Through the analysis of parameters such as equipment vibration, it can predict equipment failures in advance, optimize the equipment maintenance plan, and reduce maintenance costs.

Common Faults and Solutions

Sensor failure

Phenomenon: Abnormal monitoring data or no data output.

Cause: Sensor damage, open circuit or short circuit of the connection line, contamination of the sensor probe or improper installation.

Solution: Check whether the sensor is damaged. If it is damaged, replace the sensor; check the connection line and repair the open circuit or short circuit problem; clean the sensor probe and ensure that the installation position is correct and the installation gap meets the requirements.

Signal interference

Phenomenon: Large fluctuations in the measured data and the appearance of abnormal noise.

Cause: Strong electromagnetic interference sources nearby, improper shielding of the signal cable or poor grounding.

Solution: Locate and stay away from strong electromagnetic interference sources; check whether the shielding layer of the signal cable is intact, ensure good grounding, and if necessary, replace the cable with better shielding performance.

System communication failure

Phenomenon: The monitoring system fails to communicate normally with the host computer or other equipment.

Cause: Damage to the communication interface, incorrect communication protocol settings, network connection failure.

Solution: Check whether the communication interface is loose or damaged. If it is damaged, repair or replace it; confirm whether the communication protocol settings are consistent with those of other equipment. If there are errors, reset them; check the network connection and repair the network fault to ensure smooth communication.