Description

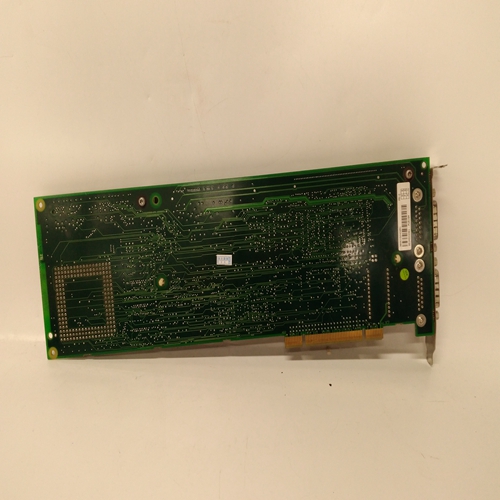

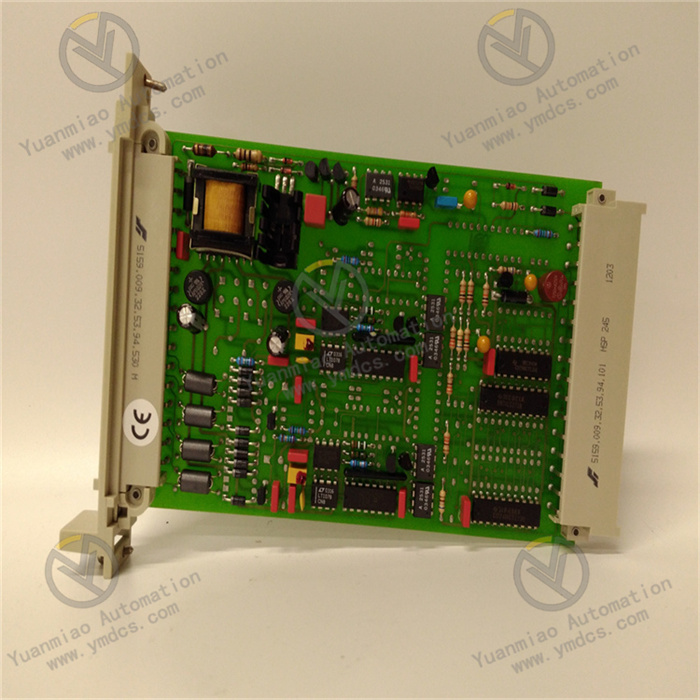

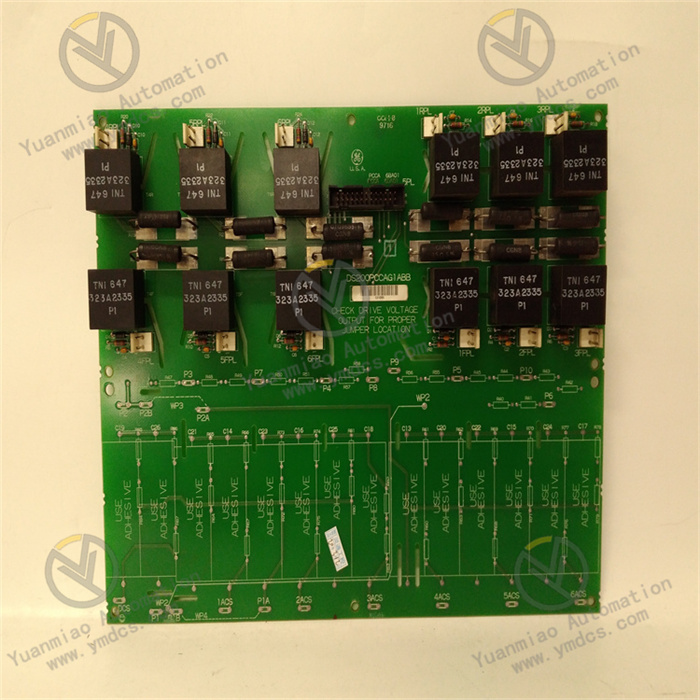

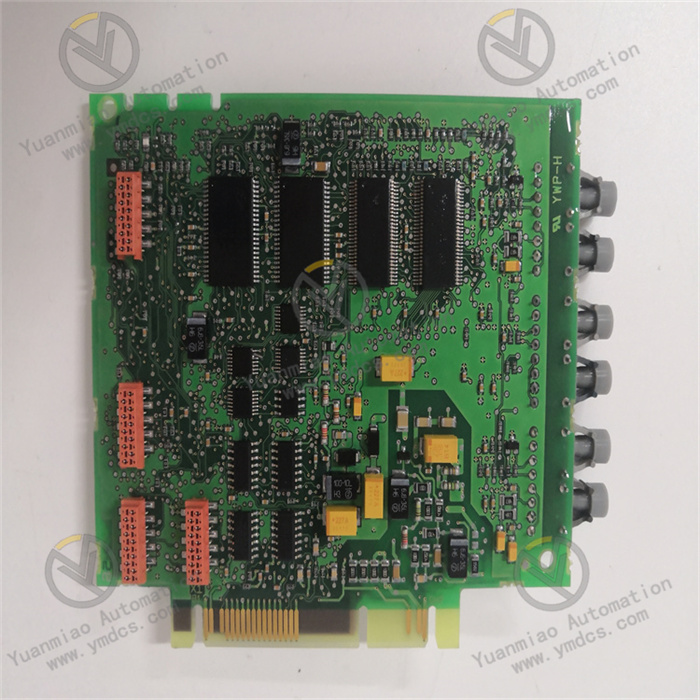

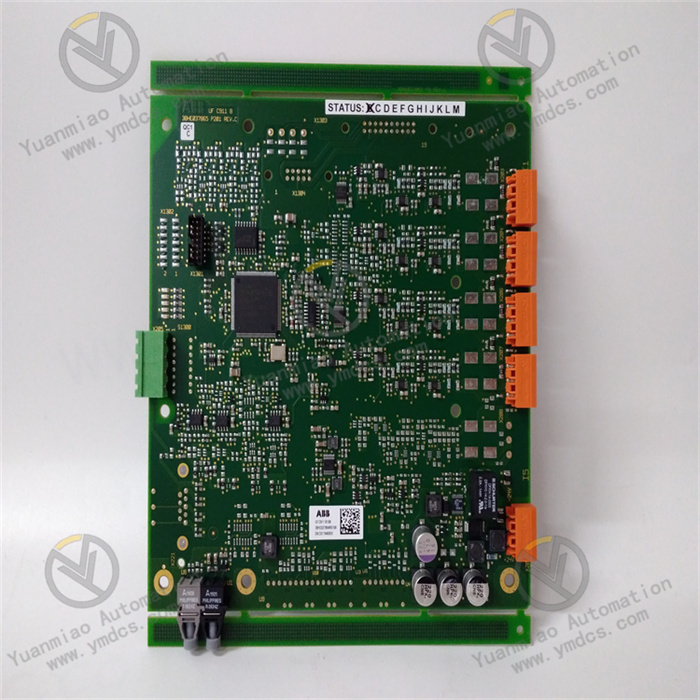

ABB CI540 3BSE001077R1

Features High Reliability: Adopting redundant design and advanced circuit protection technology, it can work stably in harsh industrial environments, ensuring the continuity of communication and the accuracy of data. Support for Multiple Communication Protocols: It supports multiple industrial communication protocols, such as Profibus - DP, Modbus, etc., enabling convenient communication with devices from different manufacturers and realizing the integration and interconnection of the system. Flexible Configuration: The communication parameters of the module, node addresses, etc. can be flexibly configured through software to adapt to different application requirements and network topologies. Strong Real-time Performance: It has fast data processing capabilities and low-latency characteristics, meeting the real-time requirements of industrial automation systems and ensuring the timely and accurate transmission of control commands and status information.

Technical Parameters Power Supply Voltage: Usually 24V DC, with an allowable voltage fluctuation range of approximately ±10%. Communication Rate: It supports multiple communication rates, such as 9.6 kbps, 19.2 kbps, 12 Mbps, etc., which can be selected according to actual application requirements. Node Capacity: It can support multiple nodes connected to the bus. The specific number depends on the communication protocol and network configuration, generally supporting 32 or more nodes. Input/Output Signal Types: It is mainly used for transmitting digital signals, including digital input/output, analog input/output, etc., and can interface with various industrial devices. Protection Level: It usually has a high protection level, such as IP20 or higher, effectively preventing the influence of dust, moisture, etc. on the module.

Application Scenarios

Manufacturing Automation Production Lines: It is used to connect various devices on the production line, such as PLCs, robots, sensors, actuators, etc., to achieve communication and collaborative work between devices, thereby improving production efficiency and product quality. For example, in the assembly line of an automobile manufacturing factory, it can connect the devices at different workstations to achieve automated production process control.

Power System Monitoring: In power systems such as power plants and substations, it is used to connect various power monitoring devices, such as relay protection devices, smart meters, measurement and control units, etc., to achieve real-time monitoring and control of the power system and ensure the safe and stable operation of the power system.

Process Control Industry: In the process control systems of industries such as chemical, petroleum, and metallurgy, it can connect distributed control systems, field instruments, actuators, etc., to achieve precise control and optimized management of the production process. For example, in the chemical production process, this module can be used to monitor and control various process parameters to ensure the safety and efficiency of the production process.

Smart Building Automation: In smart buildings, it is used to connect various intelligent devices such as air conditioning systems, lighting systems, and security systems to achieve centralized monitoring and management of the devices, improving the intelligence level of the building and the energy utilization efficiency.

When using the ABB CI540 3BSE001077R1 module, some common faults may occur. The following are some troubleshooting methods: Power Supply Fault Fault Phenomenon: The module indicator light is off, and there is no sign of communication or operation. Inspection Method: Use a multimeter to measure the input power supply voltage to ensure that it is within the range of 24V DC ±10%. Check whether the power supply connection cable is loose, damaged, or poorly connected. If there are problems, repair or replace the connection cable. If the power supply voltage is normal but the module still does not respond, it may be that the internal power circuit of the module has a fault, and professional maintenance personnel need to be contacted for inspection or replacement.

Communication Fault

Fault Phenomenon: The module cannot establish communication with other devices, or there are errors or losses in communication data transmission.

Inspection Method: First, confirm whether the communication cable is correctly connected and undamaged, and whether the interface is in good contact. Check whether the communication protocol settings are correct, including parameters such as baud rate, data bits, stop bits, and parity bits, to ensure consistency with the settings of other communication devices. Check the node address settings of the module to see if there is a conflict with the addresses of other devices in the network. If the communication line and settings are all normal, professional communication test tools such as an oscilloscope or a protocol analyzer can be used to check the quality and format of the communication signal to determine if there are interference or other problems.

Input/Output Fault Fault Phenomenon: The module cannot correctly receive input signals, or the output signals cannot normally drive external devices. Inspection Method: For input faults, check whether the type, amplitude, frequency, etc. of the input signal meet the requirements of the module. Check whether the input connection cable is correctly connected and whether there are situations such as short circuits or open circuits. For output faults, check whether the settings of the output channel are correct, including parameters such as output type and range. Use a multimeter or an oscilloscope to measure parameters such as the amplitude and frequency of the output signal to see if they match the set values. If the output signal is normal but the external device still cannot work properly, check whether the power supply of the external device is normal, whether the device itself has faults, and whether the interface between the connected device and the module is matched.

Module Overheating Fault Phenomenon: The surface temperature of the module is too high, which may lead to a decrease in performance or a fault alarm. Inspection Method: Check whether the installation environment of the module is well ventilated, and whether there are heat sources or other poor heat dissipation situations around. Ensure that the module is installed in a cabinet or panel that meets the requirements and follow the ABB installation guidelines for installation. Check the load situation of the module to see if it is operating overloaded. If the module operates under high load for a long time, it may be necessary to consider adding heat dissipation measures or optimizing the system configuration to reduce the working temperature of the module.