Description

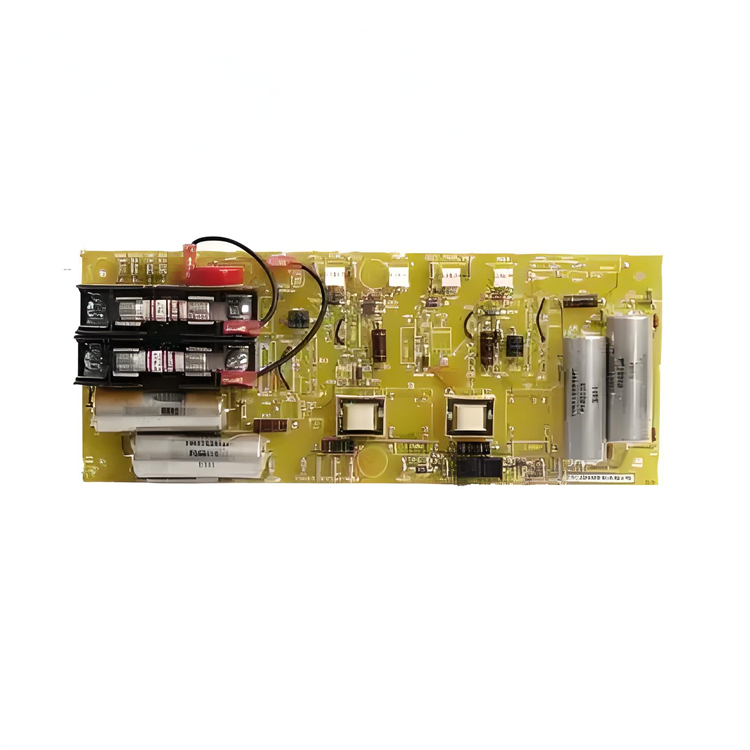

GE IC694PWR330

I. Technical Parameters

1. Input Power Parameters

- Adopts dual-channel independent input design, supporting wide-range AC or DC input. AC input range: 85-264V AC (50/60Hz); DC input range: 120-370V DC. The input type can be flexibly selected according to on-site power supply conditions without additional power adapters.

- Dual-channel input supports hot standby redundancy. When the main input circuit fails, the standby circuit can switch seamlessly within ≤10ms to ensure uninterrupted output.

- Each input channel is equipped with independent fuse protection with a rated value of 2A/250V AC, enabling rapid isolation of input-side faults.

2. Output Power Parameters

- Provides dual-channel DC output of 5V DC and 3.3V DC. The 5V DC output has a rated current of 20A and a peak current of up to 25A (sustained for 10 seconds); the 3.3V DC output has a rated current of 10A and a peak current of up to 12A (sustained for 10 seconds). The total output power can reach 133W, meeting the centralized power supply needs of RX3i series controllers, I/O modules, and expansion modules.

- High output voltage precision: 5V DC output precision is ±2%, 3.3V DC output precision is ±3%. Ripple voltage is ≤50mVpp (for 5V output) and ≤30mVpp (for 3.3V output), effectively ensuring the stable operation of load equipment.

3. Redundancy and Load Distribution Parameters

- Supports parallel connection of 2 modules to achieve N+1 redundancy. Load balancing distribution is realized through built-in redundancy control circuits with a load distribution error of ≤5%, enabling flexible expansion of power supply capacity according to system extension requirements.

- The module is equipped with a built-in redundant communication interface, enabling status synchronization and fault collaborative alarm among multiple modules. When one module fails, the remaining modules can automatically share the load to ensure the total output capacity meets system requirements.

4. Structural and Hardware Parameters

- Features a dual-slot design, compatible with RX3i series standard backplane installation. Module dimensions: 68mm×145mm×140mm, weight approximately 800g, with a compact structure and easy installation.

- The front panel is equipped with power status LED indicators (Power OK, Redundancy Status, Fault Alarm), providing intuitive feedback on input/output status, redundancy mode, and fault information.

- Equipped with a detachable power input terminal block supporting screw-fastened wiring. The wiring specification is compatible with 12-22AWG wires, facilitating on-site wiring operations.

5. Environmental and Reliability Parameters

- Complies with industrial-grade wide-temperature operation standards: operating temperature range -25℃~+60℃, storage temperature range -40℃~+85℃, suitable for outdoor cabinets in cold regions and high-temperature workshop environments.

- Relative humidity adaptation range: 5%~95% (non-condensing), meeting the requirements of high-humidity environments such as coastal areas and humid mines.

- Certified by multiple international standards including CE, UL, and CSA, supporting Class I, Division 2 hazardous area installation. The Mean Time Between Failures (MTBF) is ≥200,000 hours, ensuring extremely high operational reliability.

6. Protection and Diagnostic Parameters

- Integrates multiple protection functions:

- Input overvoltage protection (triggered when AC input ≥280V AC or DC input ≥400V DC);

- Output overvoltage protection (triggered when 5V output ≥5.6V or 3.3V output ≥3.7V);

- Output overload protection (current limiting protection triggered when load current exceeds 110% of the rated value; shutdown protection triggered when exceeding 150%);

- Overtemperature protection (triggered when the internal module temperature ≥85℃).

- Equipped with comprehensive fault diagnosis functions, capable of detecting input faults, output faults, module overheating, redundant communication faults, etc., and feeding back fault information through LED indicators and the backplane bus.

II. Key Features

1. Dual-Channel Input + Parallel Redundancy, Maximizing Power Supply Reliability

- Core highlight: Dual redundancy design combining dual-channel hot standby input and multi-module parallel redundancy.

- Dual-channel input can be connected to power sources of different circuits (e.g., main power grid and backup generator) with a fault switching time of ≤10ms, ensuring no single point of failure on the input side.

- Parallel connection of 2 modules achieves N+1 redundancy, increasing the total output capacity to 40A (5V) + 20A (3.3V). When one module fails, the other can seamlessly take over the entire load with 0 power supply interruption time. Compared with single power supply solutions, the system power supply reliability is improved by over 99.99%.

2. Wide-Range Input + Precise Output, Strong Adaptability

- 85-264V AC/120-370V DC wide-range input design is compatible with industrial power supply standards in different regions worldwide, meeting the needs of cross-border projects without replacing modules.

- Dual-channel precise output of 5V/3.3V with voltage precision of ±2% and ±3% respectively, and extremely low ripple voltage. It can directly power sensitive electronic components (e.g., CPU, sensors) to avoid equipment malfunctions caused by voltage fluctuations.

- Peak current output capability can handle inrush current during load startup, ensuring the module does not shut down due to transient overload.

3. Multiple Protections + Intelligent Diagnosis, Improving Operation and Maintenance Efficiency

- Integrates multiple protection mechanisms such as input overvoltage, output overvoltage, overload, and overtemperature, comprehensively resisting various abnormal risks of the power supply system and preventing fault propagation to load equipment.

- Comprehensive fault diagnosis function can accurately locate fault types (e.g., input phase loss, output short circuit, module overheating), displayed intuitively through LED indicators. Meanwhile, fault information is uploaded to the controller via the RX3i backplane bus, and detailed fault information can be quickly viewed through the HMI interface. Fault troubleshooting time is reduced to within 5 minutes, improving operation and maintenance efficiency by 70% compared with traditional power supply modules.

4. Compact Design + Easy Integration, Reducing Deployment Costs

- Dual-slot compact design effectively saves cabinet installation space, reducing installation space occupancy by 40% compared with traditional split-type redundant power supplies.

- Detachable terminal blocks and clear wiring marks simplify on-site wiring operations, shortening the wiring time for new system deployment or old system upgrades to within 30 minutes.

- The module is plug-and-play with the RX3i series backplane, requiring no additional redundant controllers, reducing integration costs by 30%.

III. Working Principle and Applications

3.1 Working Principle

3.2 Application Scenarios

Power Supply for Petrochemical DCS Systems: In the DCS control system of a refinery, two IC694PWR330 modules are deployed in parallel redundancy to supply power to the RX3i controller and more than 30 I/O modules. Dual-channel input is connected to the factory's main power grid and backup diesel generator respectively. When the main power grid is cut off due to failure, the backup power supply switches seamlessly within 10ms. Module parallel redundancy ensures no load interruption when a single module fails. Multiple protection functions resist voltage fluctuations of the factory power grid (within 85-264V AC), and overtemperature protection adapts to the high-temperature environment of the cabinet in summer (≤60℃). The annual power supply reliability reaches 99.999%, avoiding production shutdown losses caused by power supply interruption.

Power Supply for Thermal Power Plant PLC Control Stations: In the boiler control PLC station of a coal-fired power plant, IC694PWR330 serves as the core power supply unit, supplying power to the RX3i controller, analog input modules (e.g., IC695ALG616-EA), and digital output modules. The 5V output powers the controller CPU, and the 3.3V output powers the module communication circuit. The ±2% output precision ensures distortion-free analog acquisition data. The overvoltage protection function quickly cuts off the input when the grid voltage surges due to lightning strikes, protecting expensive control modules from damage. The wide-temperature design adapts to the temperature fluctuation of -25℃~+60℃ in the outdoor control cabinet of the power plant, and MTBF ≥200,000 hours ensures long-term stable operation.

Power Supply for Intelligent Manufacturing Production Line Control Systems: In the PLC control system of an automobile final assembly line, one IC694PWR330 module is used to supply power to the RX3i controller and 15 I/O modules. Dual-channel input is connected to the workshop's main power supply and UPS backup power supply. The peak current output capability of the module handles the inrush current during production line startup (5V output peak 25A), avoiding module shutdown due to overload. The fault diagnosis function quickly locates problems such as loose input wiring through LED indicators. Combined with fault prompts on the HMI interface, operation and maintenance personnel can complete fault handling within 5 minutes, reducing production line downtime by 80%.

- Power Supply for Rail Transit Signal Control Systems: In the signal control room of an urban subway, two IC694PWR330 modules are deployed in parallel redundancy to supply power to the RX3i signal controller. Dual-channel input is connected to the subway's dedicated power grid and emergency power supply respectively. The module supports 120-370V DC wide-range DC input, adapting to the subway DC power supply system. The redundancy switching time of ≤10ms ensures uninterrupted signal transmission. Overtemperature protection and overvoltage protection resist high temperatures and voltage fluctuations caused by dense equipment in the equipment room, ensuring the continuous and reliable operation of the subway signal system.

IV. Common Faults and Troubleshooting

1. Fault 1: Abnormal Output Voltage (Low or High)

- Possible Causes: Input voltage out of range, excessive output load, internal voltage regulation circuit failure of the module, loose wiring terminals.

- Troubleshooting Measures:① Use a multimeter to measure the input voltage, ensuring it is within the range of 85-264V AC or 120-370V DC. Install a voltage stabilizer if it exceeds the range.② Check the total output load current. If it exceeds the rated value (5V 20A/3.3V 10A), reduce the load or add parallel modules.③ Perform a power-off restart of the module. Replace with a spare module if the abnormality persists.④ Check the tightness of the input and output terminal blocks, and re-tighten loose wiring.

2. Fault 2: Redundancy Mode Failure (Redundancy Indicator Off)

- Possible Causes: Redundant communication cable not connected, incorrect configuration of module redundancy parameters, failure of one of the modules, poor contact of backplane slots.

- Troubleshooting Measures:① Check the redundant communication cable between the two modules to ensure it is firmly connected and undamaged.② Log in to the controller configuration software and verify the redundancy mode parameter configuration (e.g., load distribution ratio).③ Test each module individually and re-parallel them after confirming no faults.④ Turn off the power, reinsert the modules to ensure good contact with the backplane, and clean foreign objects in the slots.

3. Fault 3: Module Reports Overtemperature Fault (Overtemperature Indicator On)

- Possible Causes: Poor cabinet ventilation, insufficient module installation spacing, ambient temperature out of range, failure of the internal cooling fan of the module.

- Troubleshooting Measures:① Check the operation status of the cabinet cooling fan. Replace it if damaged and ensure the cabinet air inlet is unobstructed.② Adjust the module installation spacing to ≥10cm to ensure heat dissipation space.③ Measure the internal temperature of the cabinet. Install an air conditioner or cooling fan if the temperature exceeds 60℃.④ Disassemble the module to check the internal cooling fan. Contact the manufacturer for repair or replacement if faulty.

4. Fault 4: Output Short Circuit Protection Triggered (No Output Voltage)

- Possible Causes: Short circuit of output terminal wiring, internal short circuit of load equipment, failure of the module output circuit.

- Troubleshooting Measures:① Disconnect all loads and power on the module alone. If the output is restored, it indicates a load short circuit. Troubleshoot load equipment one by one.② Use a multimeter to measure the resistance between output terminals. Reconnect the load after confirming no short circuit.③ If there is still no output after disconnecting the load, test with a spare module. Return the original module for repair after confirming the fault.