Description

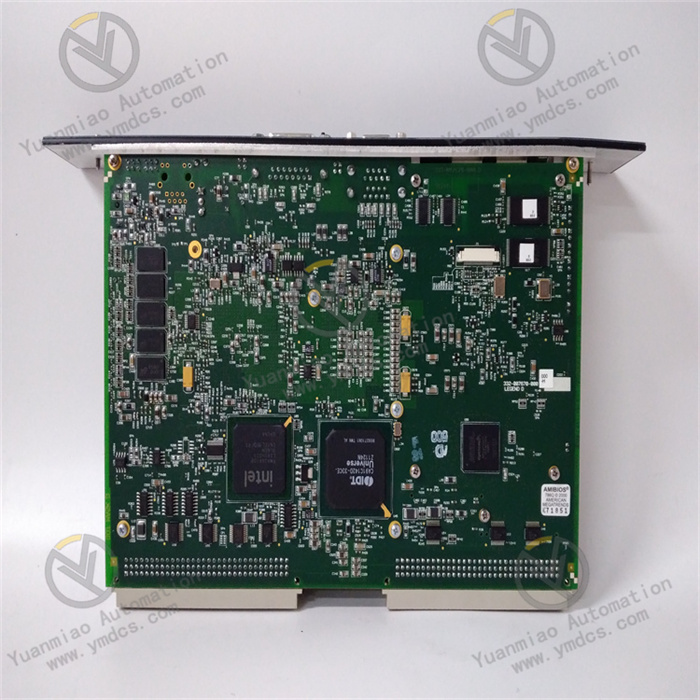

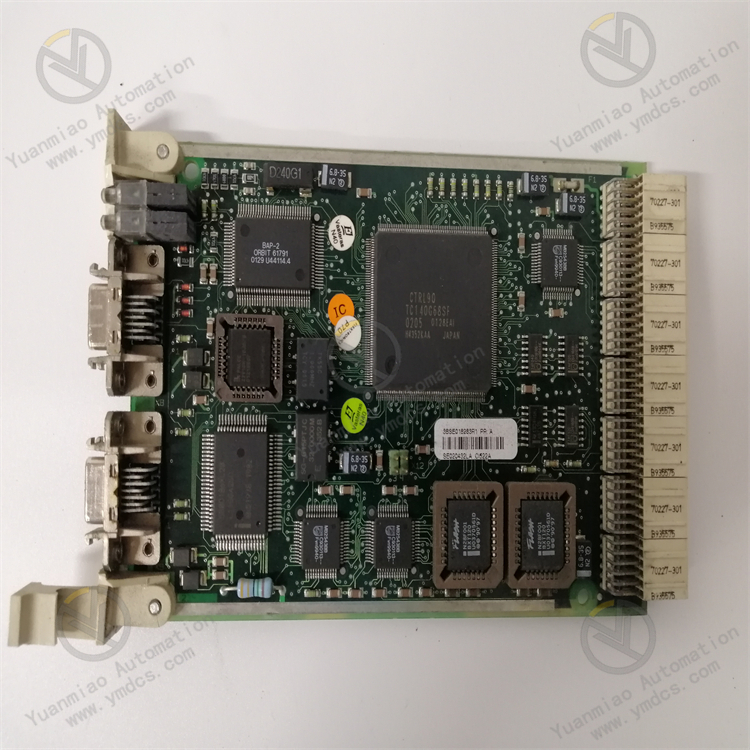

GE IC698CPE010

The GE IC698CPE010 is a CPU module of the PACSystems RX7i series. Serving as the "core brain" of industrial automation control systems, it integrates high-performance computing, multi-protocol communication, and high-reliability redundancy design into one, specifically built for medium-to-large-scale complex industrial control scenarios. Relying on its outstanding processing capability and flexible expansion features, it has become a preferred control core in fields such as intelligent manufacturing, energy management and control, and chemical process control, providing efficient and stable control solutions for automation engineers and operation and maintenance personnel.

I. Technical Parameters

- Computing Performance: Equipped with a multi-core 32-bit processor with a main frequency of 1.2GHz, supporting parallel task scheduling. The execution speed of control programs reaches 0.1μs/instruction. It has a program storage capacity of 128MB Flash and a data storage capacity of 64MB RAM, and supports SD card expansion up to 2GB, meeting the needs of complex logic and big data processing.

- Communication Capability: Standard configuration includes 2 Gigabit Ethernet ports (supporting PROFINET and EtherNet/IP) and 4 RS485 ports (compatible with Modbus-RTU). It can be expanded with fiber optic communication modules to achieve long-distance transmission. It supports 128 concurrent communication connections with a communication delay of ≤1ms, ensuring real-time data interaction.

- Redundancy and Expansion: Supports CPU dual-machine hot standby redundancy with a switching time of ≤10ms. It is compatible with the full range of RX7i I/O modules, allowing maximum expansion of 256 I/O points, and supports mixed configuration of analog, digital, and special function modules (such as high-speed counting and pulse output).

- Environmental Adaptability: Operating temperature ranges from -20℃ to 70℃, and storage temperature ranges from -40℃ to 85℃. Relative humidity is 5%-95% (non-condensing). Electromagnetic interference resistance complies with the IEC 61000-4 series standards. It has an IP20 protection rating and supports DIN rail or cabinet installation.

II. Functional Features

With "high performance, high reliability, and high flexibility" as its core advantages, the IC698CPE010 is suitable for complex industrial scenarios:

- Multi-Core Parallel Computing for Enhanced Control Real-Time Performance: Adopting a multi-core architecture, the main core is responsible for core control logic computing, while the auxiliary cores handle communication interaction and fault diagnosis, avoiding overload of a single core. In multi-loop control scenarios, it can manage 64 PID loops simultaneously with a regulation accuracy of ±0.05%FS, far exceeding traditional single-core CPU modules.

- Full Redundancy Design to Ensure Operational Continuity: Supports triple redundancy configuration of CPU, power supply, and communication. In dual-machine hot standby mode, programs and data are synchronized in real time, with no data loss during fault switching. It meets the "zero downtime" requirement in critical scenarios such as chemical and power industries, with a Mean Time Between Failures (MTBF) of ≥200,000 hours.

- Multi-Protocol Compatibility for Cross-System Interconnection: Natively supports mainstream protocols of industrial Ethernet and fieldbuses, enabling seamless connection with equipment of brands such as GE, Siemens, and Rockwell, easily breaking the "protocol island". It realizes data intercommunication between the control layer and the information layer through Gigabit Ethernet, supporting intelligent manufacturing data collection in Industry 4.0 scenarios.

- Intelligent Diagnosis and Maintenance to Reduce Management Costs: Built-in full-link diagnosis function covering "module-channel-communication". Fault information is indicated by both LED indicators and diagnostic software, with a positioning accuracy reaching the channel level. It supports remote program download, online debugging, and firmware upgrade, reducing on-site operation and maintenance workload.

III. Working Principle

The IC698CPE010 follows the closed-loop logic of "data collection - computing processing - control output - status feedback" and achieves efficient control by combining with a multi-core architecture:

- Data Collection: On-site sensor signals (such as temperature, pressure, and position) are collected through I/O modules and transmitted to the CPU via the internal bus. The signal transmission process undergoes filtering and isolation treatment to suppress electromagnetic interference.

- Computing Processing: The multi-core processor calls preset control programs (such as logic interlocking and PID regulation). The main core executes core computing, while the auxiliary cores synchronously process communication data and diagnostic information, realizing real-time data interaction through shared memory.

- Control Output: The computing results are converted into execution signals by the output module to drive the action of executive mechanisms such as valves and motors. In redundancy mode, the standby CPU verifies the main core data in real time to ensure output consistency.

- Status Feedback: It monitors the operating status of each module in real time, and uploads fault information and operating data to the HMI or SCADA system to realize visual monitoring and fault early warning.

IV. Typical Application Scenarios

With its powerful performance, this module is widely used in various key industrial scenarios:

- Intelligent Manufacturing Production Lines: Used for collaborative control of production lines such as automobile welding and electronic component assembly. It realizes multi-equipment linkage and precise adjustment of process parameters, improving production efficiency by more than 15%.

- Chemical Process Control: Adapted for multi-variable coupling control of reactor temperature, pressure, etc. The redundancy design ensures the continuous operation of chemical production and avoids economic losses caused by shutdowns.

- Energy Management and Control Systems: Used for unit coordination and energy dispatching in thermal power plants and photovoltaic power stations. It processes massive monitoring data in real time and optimizes energy utilization efficiency.