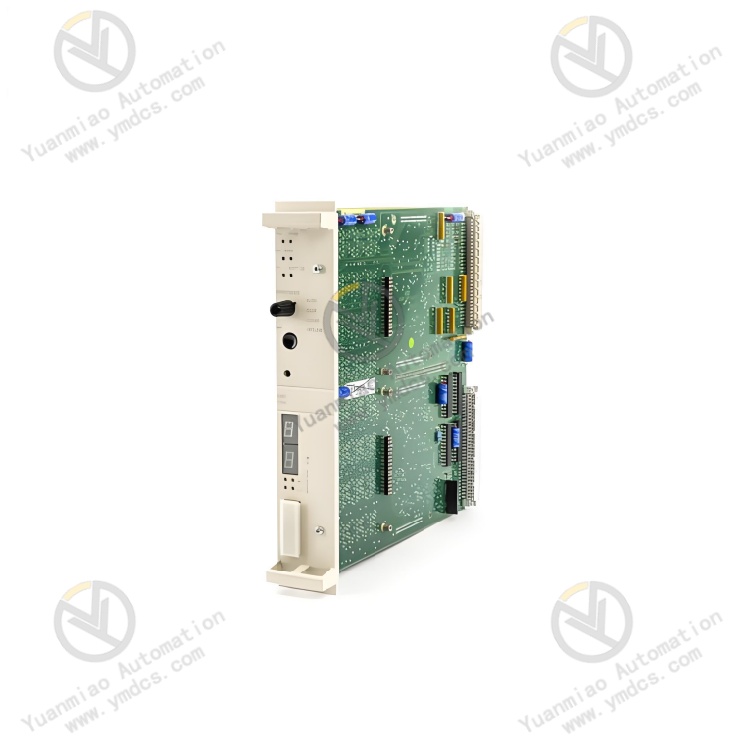

Description

Functional Features

1. High-precision Data Collection: It can accurately collect various types of analog data, such as voltage, current, temperature, pressure, etc. It has a high resolution and measurement accuracy, providing accurate data support for the monitoring of industrial processes.

2. Communication Capability: It supports multiple communication protocols, such as Ethernet communication, serial communication, etc. It can stably transmit data with other devices (such as PLC, host computer, sensors, actuators, etc.), enabling system integration and remote monitoring.

3. Signal Processing and Conversion: It processes and converts the collected analog signals, transforming them into digital signals for analysis and processing by the computer system. Meanwhile, it may have functions such as filtering, amplification, and isolation to improve the quality and stability of the signals.

4. Reliability and Stability: It uses high-quality electronic components and advanced manufacturing processes, and has strong anti-interference ability. It can operate stably in harsh industrial environments (such as high temperature, high humidity, strong electromagnetic interference, etc.), reducing the occurrence of equipment failures.

5. Flexible Configuration: Users can flexibly configure the module according to actual application requirements, such as setting input ranges, communication parameters, data collection frequencies, etc., to adapt to different industrial control scenarios.

Technical Parameters 1. Power Requirements: It may require a specific power supply voltage, such as 24V DC or 220V AC, etc., to ensure the normal operation of the equipment, and there may also be corresponding specifications for the power requirements of the power supply. 2. Analog Input Channels: It may have multiple analog input channels, for example, 8 or 16 analog input channels, and can collect multiple analog signals simultaneously. 3. Measurement Accuracy: The analog input accuracy may reach ±0.1% FS (full scale) or higher, and can accurately measure the changes of input signals. 4. Communication Rate: The Ethernet communication rate may reach 10/100Mbps, and the serial communication rate can be in the range of 9600bps to 115200bps, specifically depending on the communication protocol and device settings. 5. Operating Temperature Range: The general operating temperature range may be between -10°C and 55°C, adapting to different industrial environment temperatures. Application Areas 1. Industrial Automation Production Lines: In the automation production lines of industries such as automotive manufacturing, electronic manufacturing, and food processing, it is used to collect various parameters in the production process, such as temperature, pressure, flow rate, liquid level, etc., to achieve precise control and monitoring of the production process and improve production efficiency and product quality. 2. Power Systems: It can be used for monitoring the equipment status in substations, such as measuring and monitoring parameters like the oil temperature, voltage, current, and power of transformers to ensure the stable operation of the power system. At the same time, in the power distribution system, it can monitor and control the power parameters in real time. 3. Chemical Industry: In the chemical production process, it can accurately measure and control parameters such as the temperature, pressure, liquid level, and composition of the reaction kettle to ensure the safety and stability of chemical production. For example, it can monitor the temperature and pressure inside the reaction kettle and adjust the production process parameters in a timely manner. 4. Smart Buildings: It participates in the automation control system of smart buildings, collecting and controlling parameters such as the temperature, humidity, wind speed of the air conditioning system, and the current, voltage, and switch status of the lighting system to achieve intelligent management of the building and energy optimization.

Common Faults and Solutions

1. Communication Faults

Reasons: Damaged communication cables, loose communication interfaces, incorrect communication parameter settings, communication module failures, etc.

Solutions: Check whether the communication cables are properly connected and if there is any damage, and replace the cables if there are problems; check whether the communication interfaces are loose and re-plug them; confirm whether the communication parameter settings, such as baud rate, data bits, stop bits, parity check, etc., are correct, and re-set the correct parameters; if the communication module is suspected to be faulty, use professional detection equipment for detection and replace the module if there are problems.

2. Measurement Errors

Reasons: Sensor failures, interference of input signals, improper setting of the measurement range, internal circuit failures of the module, etc.

Solutions: Check whether the sensors are working properly and replace the faulty sensors; take electromagnetic shielding measures to reduce the interference of input signals; check whether the measurement range setting is reasonable and adjust the measurement range according to the actual signal size; if internal circuit failures of the module are suspected, use professional detection equipment for detection, find the fault points and repair or replace the relevant components.

3. Power Supply Faults

Reasons: Damaged power supply modules, abnormal power input (such as unstable voltage, reverse polarity, etc.).

Solutions: Check whether the power supply modules have phenomena such as overheating and damage, and replace the faulty power supply modules; check whether the power input voltage is within the allowable range of the equipment and whether the power polarity is correct to ensure normal power input.

4. Module Faults

Reasons: Damaged electronic components, overvoltage, overcurrent, too high or too low environmental temperature, etc.

Solutions: Use professional detection equipment to detect the module, find and replace the faulty components; check whether the module is affected by overvoltage and overcurrent and take corresponding protection measures, such as installing overvoltage and overcurrent protection devices; ensure that the operating environment temperature of the module is within the specified range, and take heat dissipation or thermal insulation measures if the environmental temperature is too high or too low.