Description

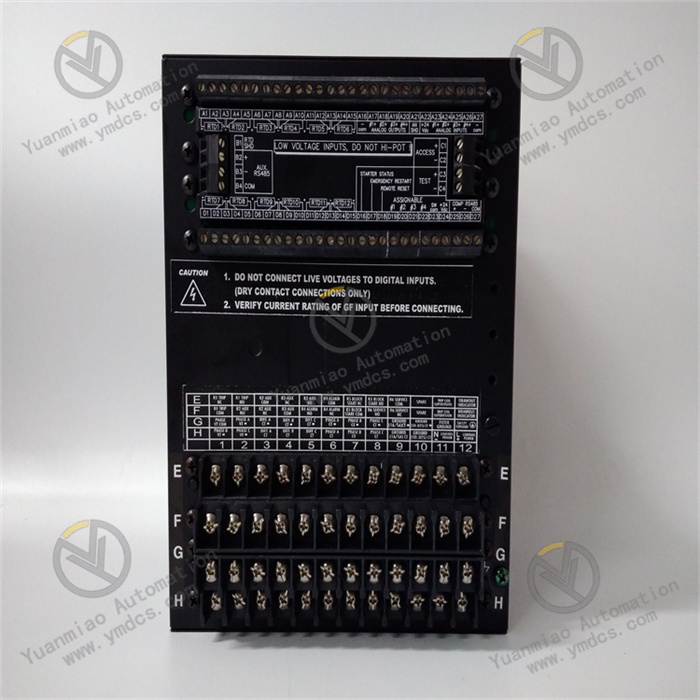

GE Multilin SR469-P5-HI-A20-H

The GE Multilin SR469-P5-HI-A20-H is an integrated motor protection relay specifically tailored for high-voltage (rated voltage ≤ 35kV), high-power (rated power ≥ 10MW) asynchronous motors, synchronous motors, and special rotating equipment. Positioned as an "intelligent protection and operation & maintenance management terminal for the full lifecycle of high-voltage and high-power motors", its core value lies in integrating high-precision electrical quantity collection, multi-physical quantity fusion diagnosis, millisecond-level protection action, and full-scenario data interaction capabilities. It achieves precise protection throughout the entire stages of motor startup, loading, steady-state operation, shutdown, and fault emergency response. Meanwhile, it integrates advanced functions such as equipment health assessment, remote operation & maintenance, and system linkage control, providing an integrated "protection-monitoring-diagnosis-operation & maintenance" solution for key equipment in fields like electric power, new energy, metallurgy, and heavy manufacturing—including large turbine generators, main steel rolling motors, mine hoists, and fan-pump units.

With core advantages of "ultra-precise measurement, full-dimensional protection, intelligent diagnosis, and high-reliability operation", this relay is highly adaptable to the harsh operating conditions of high-voltage and high-power motors, such as high voltage, large current, high load fluctuation, and long-term operation. It serves as the core hub for closed-loop management of "fault early warning-rapid removal-root cause analysis-health management" in industrial motor drive systems. It performs exceptionally well in key industry scenarios:

- In the electric power field, it is used to protect primary air fans and boiler feedwater pump motors in thermal power plants. It can accurately detect hidden faults like rotor bar breakage and air gap eccentricity, issue early warnings more than 30 days in advance, and reduce the unplanned shutdown rate by 60%.

- In the metallurgical field, it is suitable for main steel rolling motors with power above 15,000kW. It can withstand the impact of frequent startups and shutdowns (≤ 10 times per hour), and its short-circuit protection action time is ≤ 8ms, preventing roll damage caused by fault escalation.

- In the new energy field, it provides wide-voltage range protection (6kV-35kV) for high-voltage asynchronous motors supporting photovoltaic/wind power systems. It adapts to extreme scenarios with grid voltage fluctuations of ±20%, ensuring stable grid connection of power generation systems.

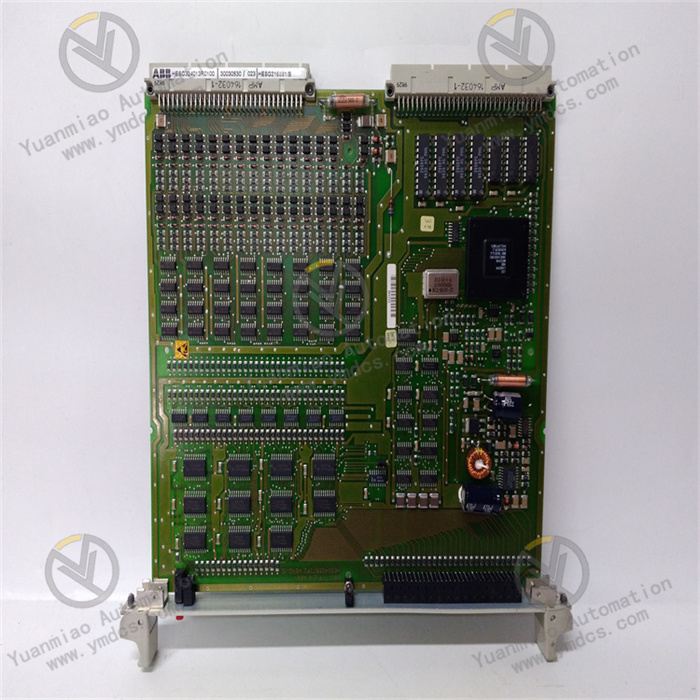

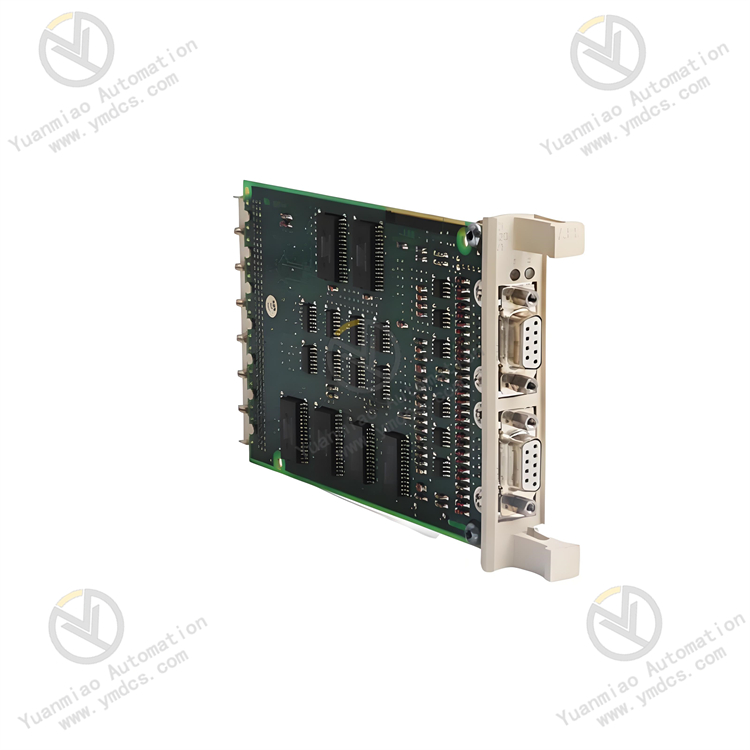

The hardware architecture adopts a flagship-level design of "quad-core processor + multi-channel high-precision collection + full redundancy design". Its core consists of a 32-bit quad-core industrial-grade DSP+ARM heterogeneous processor, a 24-bit high-precision A/D sampling chip, 12 independent protection output interfaces, and a multi-protocol redundant communication module. It is equipped with 6-phase current input channels (compatible with programmable CT ratios from 1:1 to 1:20,000, supporting dual CT parallel redundancy), 4 voltage input channels (compatible with multiple voltage levels including 100V/220V/400V/1000V, supporting PT open-circuit detection), 16 digital input channels (including 4 high-speed DIs with response time ≤ 1μs), and 12 relay output channels (with capacity of AC250V/10A and DC24V/15A, supporting custom functions like tripping, alarming, and interlock control). It has built-in triple redundant communication interfaces (RS485, EtherNet/IP, and Profinet), enabling seamless access to industrial Internet platforms such as GE Predix and Siemens TIA Portal. Its protection functions cover more than 25 types of motor faults, including overload (optional inverse time/definite time/energy accumulation type), short circuit (instantaneous trip/delayed instantaneous trip/time-limited instantaneous trip), grounding (zero-sequence current/residual current/directional grounding), locked rotor, phase loss, under-voltage/over-voltage/unbalance, rotor bar breakage, shaft current, winding temperature, and bearing temperature. It supports custom logical interlock relationships via configuration software. The industrial-grade reinforced design uses wide-temperature military-grade components (-40℃~85℃), a double-layer metal shielded enclosure (shielding effectiveness ≥ 100dB), and enhanced anti-electromagnetic interference circuits. It complies with high international standards such as IEC 61850-3 and IEC 60255-27, and can operate stably in extreme industrial sites with strong electromagnetic interference, high dust, high humidity, and high altitude (≤ 5,000m).

Breaking through the limitations of traditional single electrical quantity protection, it builds a multi-dimensional fusion protection system of "electrical parameters + temperature + vibration + oil quality". In terms of electrical protection:

- It adopts 256-point/cycle high-precision sampling and quad-core processor parallel computing, compressing the short-circuit protection action time to ≤ 8ms (20% faster than the standard version). This enables rapid interruption of short-circuit faults in 35kV high-voltage systems, reducing the impact of fault energy release on motor insulation.

- Rotor bar breakage protection integrates current spectrum analysis and vibration feature recognition. It extracts fault characteristic frequencies (e.g., 2sf±f1) via FFT algorithm and combines with vibration acceleration peak monitoring, improving the bar breakage detection accuracy from 0.5% (standard version) to 0.1% and enabling early warning of hidden faults.

In terms of non-electrical quantity protection:

- 8 high-precision temperature input channels can simultaneously monitor temperatures of key parts such as stator windings, rotors, and bearings, supporting temperature gradient alarms (e.g., alarm for excessive temperature rise of 10℃/min).

- 2 vibration input channels are compatible with industrial vibration sensors, real-time monitoring radial/axial vibration of the motor. Combined with the vibration threshold database in the equipment ledger, it achieves adaptive protection under different rotational speeds.

All protection logics support "AND/OR/NOT" combination programming, allowing customization of complex scenarios such as "excessive vibration + temperature over-limit" interlock tripping to meet the personalized protection needs of special motors.

Adopting a full-link redundancy design of "power supply-collection-communication-output", it meets the high reliability requirements of critical scenarios such as nuclear power plants and metallurgical main drives.

- The power supply system is configured with dual main/backup power supplies (AC/DC 85V~265V main power + DC 24V backup power). An intelligent power management module enables seamless switching (switching time ≤ 1ms), avoiding protection failure caused by single power supply faults.

- The current/voltage collection circuit supports dual CT/PT parallel input. When the main collection channel fails, the backup channel automatically takes over within 5ms, with a collection data accuracy deviation ≤ 0.05%.

- The communication system is equipped with 2 EtherNet/IP and 2 RS485 interfaces, supporting dual-network port hot backup and communication link diagnosis. When the main communication link is interrupted, it switches to the backup link within 100ms, ensuring data continuity with the monitoring system.

- The output circuit adopts a design of 8 main relays + 4 backup relays. When the contact wear of the main relay exceeds the limit, the system automatically switches to the backup relay and issues a contact maintenance alarm, extending the equipment's fault-free operation time.

The full redundancy design increases the equipment's MTBF to ≥ 500,000 hours (150% higher than the standard version), enabling the operation & maintenance goal of "zero unplanned shutdowns" in continuous production scenarios.

It integrates GE's patented "Equipment Health Index (HI)" evaluation model, realizing quantitative assessment of motor health status through multi-source data fusion.

- At the data collection level: It collects electrical parameters at a sampling frequency of 12.8kHz and non-electrical parameters (temperature, vibration, etc.) at 1-minute intervals. The 1-year trend data storage provides a data foundation for health analysis.

- At the diagnostic algorithm level: Based on machine learning models (e.g., random forest algorithm), it analyzes historical data to establish a "digital twin" baseline for normal motor operation. When real-time data deviates from the baseline by ±5%, it automatically initiates the diagnostic process to identify fault types (e.g., bearing wear, uneven air gap) and locate fault locations, with a diagnostic accuracy ≥ 90%.

- At the health assessment level: It calculates the health index (0-100 points) via a weighted algorithm—80-100 points for "healthy", 60-80 points for "sub-healthy" (needing attention), and < 60 points for "fault risk" (needing maintenance). The system automatically generates a health report, including fault early warnings, remaining life prediction (based on the Arrhenius aging model), and maintenance recommendations (e.g., bearing lubrication cycle reminders).

It supports uploading health data to industrial Internet platforms (e.g., GE Predix) via EtherNet/IP, realizing centralized health management of multiple devices and upgrading traditional "post-failure maintenance" to "predictive maintenance", reducing maintenance costs by more than 30%.

It features "wide range-multi-protocol-expandable" system integration capabilities, adapting to full-scenario needs from low-voltage to high-voltage (≤ 35kV) and from ordinary motors to special motors (e.g., permanent magnet synchronous motors).

- In terms of range adaptability: The current measurement range is extended to 0.05A~20kA (via CT), and the voltage measurement range to 10V~35kV (via PT), supporting parameter collection for high-power motors above 10MW.

- In terms of protocol compatibility: In addition to supporting general protocols such as Modbus and EtherNet/IP, it is also compatible with IEC 61850-8-1 (smart substation standard) and Profinet (Siemens industrial Ethernet standard), enabling seamless access to monitoring systems of different manufacturers (e.g., GE CIMPLICITY, Siemens WinCC, Schneider EcoStruxure).

- In terms of hardware expansion: 4 module slots are reserved, allowing addition of oil quality monitoring modules (monitoring parameters such as moisture and dielectric loss), GPS clock synchronization modules (time synchronization accuracy ±1μs), and infrared temperature measurement modules (non-contact monitoring of winding temperature) to meet functional expansion needs in special scenarios.

The panel is equipped with a 320×240 dot-matrix color LCD display, supporting multi-language display (Chinese/English/Russian, etc.). The operation interface adopts a graphical design, allowing direct viewing of fault waveforms and health curves, improving on-site operation & maintenance efficiency.

![]()