Description

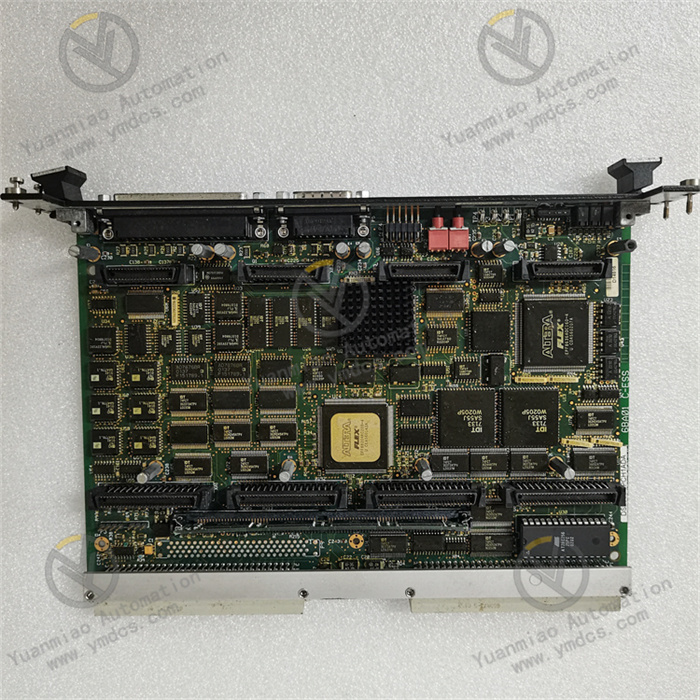

GE DS200DSPCH1A

I. Overview

The GE DS200DSPCH1A is a Digital Signal Processing (DSP) control board. Its core value lies in providing a solution featuring "high real-time control, high-power power electronic drive, and multi-dimensional condition monitoring" for turbine-generator units. Serving as the "control brain" of the unit, it undertakes core tasks such as speed regulation, load control, excitation drive, and fault protection. Leveraging a high-speed DSP chip, it enables millisecond-level control algorithm computation to drive unit actuators (e.g., servo valves, frequency converters). It is suitable for large-scale turbine control scenarios in fields such as thermal power generation, combined cycle power generation, and industrial drives, and is a key core component ensuring "safe and stable operation as well as efficient and energy-saving power generation" of the unit.

This module adopts a reinforced anti-vibration design and a redundant architecture. It supports seamless integration with I/O modules (e.g., IS200 series) and communication modules of the Mark VIe system, and offers long-term operational reliability. It serves as the core computing and drive unit in GE's turbine control system.

II. Technical Parameters

(I) Computing and Control Parameters

1. Processor and Computing Performance

- Core Chip: 32-bit high-performance DSP processor (e.g., TI TMS320 series) with a computing speed of ≥1500 MIPS (millions of instructions per second). It supports floating-point arithmetic and parallel processing, meeting the high-speed control requirements of turbine speed regulation (control cycle ≤1ms) and PID regulation (sampling cycle ≤0.1ms).

- Control Algorithms: Built-in dedicated control algorithm library for turbines, including:

- Speed closed-loop control (speed regulation accuracy of ±0.01% of rated speed, suitable for 3000rpm/3600rpm turbines);

- Load control algorithm (load response speed ≤100ms, meeting the requirements of grid AGC frequency regulation);

- Excitation regulation algorithm (excitation voltage regulation accuracy of ±0.5%, supporting brushless excitation systems).

- Control Cycle: The core control cycle is ≤1ms (for speed and load control), and the auxiliary control cycle is ≤10ms (for temperature and pressure monitoring), which is much faster than that of general-purpose PLCs (e.g., the 20ms full-load cycle of IC695CPU320-CF).

2. Signal Input and Output Configuration

- Analog Input: 8 channels of high-precision analog input (16-bit AD, input range of ±10V DC/4-20mA) for collecting signals from turbine speed sensors (e.g., magnetoresistive sensors), shaft vibration sensors, and oil pressure sensors, with an input accuracy of ±0.05% FS.

- Analog Output: 6 channels of analog output (16-bit DA, output range of ±10V DC/4-20mA) for driving servo valves (controlling turbine governor valve opening) and excitation regulators, with an output accuracy of ±0.1% FS.

- Digital I/O: 16 channels of digital input (24V DC) for collecting emergency stop signals and limit switch status; 12 channels of digital output (24V DC) for driving alarm lights and relays, with an output current of ≤2A.

- Pulse Input: 2 channels of high-speed pulse input (maximum frequency of 1MHz) for connecting to turbine speed pulse sensors, with a speed measurement resolution of ±1rpm.

(II) Power Electronic Drive and Redundancy Parameters

1. Drive Capability

- Power Drive Interface: Built-in 4-channel power amplifier circuit, supporting direct driving of turbine servo valves (output current ≤5A, voltage of ±15V DC) without the need for additional power modules. It is compatible with Moog G761 series servo valves.

- Excitation Drive: Supports communication with excitation power units (e.g., GE EX2100 excitation system), and outputs excitation control signals (PWM pulses, frequency of 10kHz-20kHz) to control the excitation current of ≤1000A (suitable for turbine-generator units below 100MW).

- Overload Capacity: The power output channel has a 1.5x overload capacity (duration ≤100ms), adapting to the instantaneous load impact during turbine start-up and shutdown.

2. Redundancy Configuration

- Module Redundancy: Supports "1+1" hot-standby redundancy configuration (2 DS200DSPCH1A modules operating synchronously). The redundancy switchover time is ≤100μs (from the failure of the main module to the takeover by the standby module), ensuring no control interruption and meeting the continuous operation requirements of the turbine.

- Communication Redundancy: Built-in dual-channel optical fiber communication interface (speed of 100Mbps) for redundant communication with Mark VIe controllers (e.g., IS200TBSCH1A). The communication delay is ≤100μs, avoiding control failure caused by communication faults.

- Power Redundancy: Supports dual-channel 24V DC redundant power supply (input voltage range of 18V-30V DC). The power consumption of a single module is ≤15W (under full-load computing and driving), and automatic switchover occurs in case of power failure, ensuring no power supply interruption.

(III) Electrical and Environmental Parameters (Suitable for Turbine Room Scenarios)

1. Isolation and Anti-Interference

- Isolation Performance:

- Signal Isolation: There is 2500V AC isolation (withstand voltage for 1 minute) between analog I/O and the processor, and 1500V AC isolation between digital I/O and the processor. It has a common-mode interference resistance voltage of ±500V DC, resisting strong electromagnetic interference in the turbine room (e.g., interference from motors and frequency converters).

- Power Isolation: There is 2000V AC isolation between the input power supply and the internal circuit, with power ripple suppression of ≤50mV (peak-to-peak).

- Electromagnetic Compatibility: Passes IEC 61000-4-2 (±15kV air discharge), IEC 61000-4-4 (±4kV electrical fast transient), and IEC 61000-4-6 (30V/m radio frequency radiation) tests, far exceeding the anti-interference level of general-purpose PLCs.

2. Environmental Adaptability

- Operating Environment: Temperature range of -10℃ to 70℃ (operation without derating, suitable for the high-temperature environment of turbine rooms); storage temperature range of -40℃ to 85℃; relative humidity of 5%-95% RH (no condensation, supporting the humid environment of turbine rooms).

- Anti-Vibration Performance: Complies with IEC 60068-2-6 standard, with a vibration frequency of 10Hz-2000Hz and an acceleration of ≤50m/s² (suitable for the vibration environment during turbine operation). The Mean Time Between Failures (MTBF) of the module is ≥200,000 hours.

- Protection Level: The module itself has an IP20 protection rating (to be installed in a Mark VIe standard control cabinet). The PCB board adopts a reinforced conformal coating (oil-proof and dust-proof, adapting to the oily environment of turbine rooms).

(IV) Communication and System Compatibility Parameters

1. Communication Interfaces

- Internal Communication: Dual-channel optical fiber interface (connecting to Mark VIe I/O racks, supporting GE's dedicated high-speed protocol) with a data update cycle of ≤1ms.

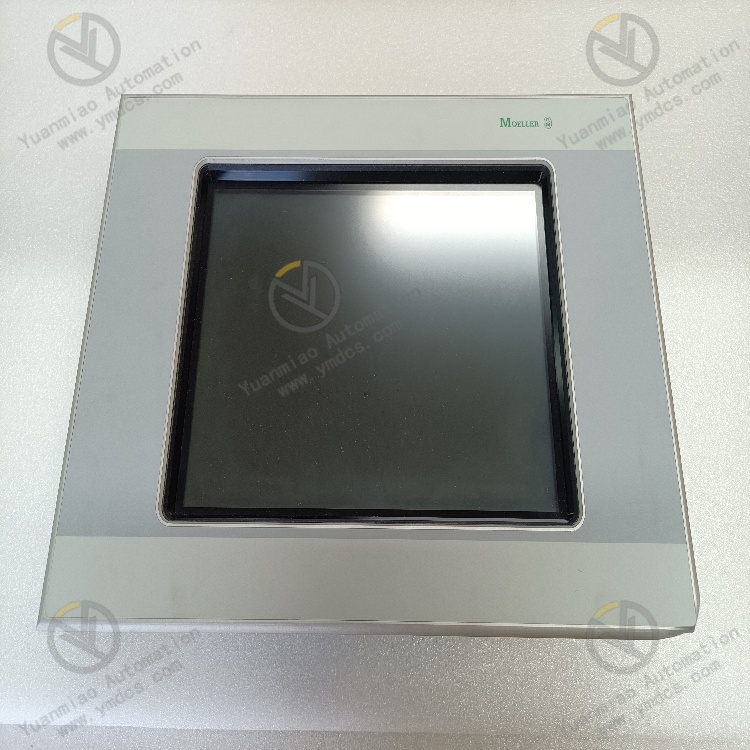

- External Communication: 1 EtherNet/IP port (10/100Mbps) for connecting to HMI and historian databases (e.g., GE Proficy Historian) to transmit turbine operation data; 1 RS-485 port (supporting Modbus RTU protocol) for connecting to third-party monitoring equipment such as vibration analyzers.

- Synchronous Communication: 1 synchronous clock interface (supporting IRIG-B code input) for synchronization with the grid clock, with a time synchronization accuracy of ±1ms, meeting the timestamp requirements of grid dispatching.

2. System Compatibility

- Software Support: Compatible with GE Mark VIe ControlST V10.0 and above versions. It supports graphical configuration of control parameters (e.g., speed setpoint, PID parameters), online downloading of control programs, and real-time monitoring of turbine operation status.

- Module Compatibility: Directly compatible with Mark VIe series I/O modules (e.g., IS200WSVOH1AE analog output module, IS200EGDMH1ADF excitation pulse module) and power modules (e.g., IS200PWRCH1A), without the need for dedicated drivers.

- Diagnostic Function: Built-in dedicated diagnostic library for turbines, capable of monitoring over 20 types of turbine-specific faults such as "speed sensor fault", "servo valve jamming", and "excessive shaft vibration", with a fault diagnosis accuracy of ≥95%.

III. Functional Features

(I) High-Speed Computing and Precise Control for Stable Turbine Operation

The high-performance DSP processor and dedicated control algorithms enable millisecond-level precise control of turbine speed and load. In the control of a 300MW thermal power unit turbine:

- The DS200DSPCH1A collects signals from the turbine speed sensor through high-speed pulse input (1MHz sampling frequency). The DSP processor completes speed calculation and PID regulation within 1ms, and outputs control signals to drive the governor valve servo valve. The speed regulation accuracy is ±0.3rpm (for a rated speed of 3000rpm), which is much higher than that of general-purpose PLCs.

- When the grid load changes (e.g., AGC command increases from 200MW to 250MW), the module responds to the load command within 100ms, adjusts the governor valve opening and fuel supply, and controls the load fluctuation to ≤±2MW, meeting the grid frequency regulation requirements and avoiding the risk of unit disconnection from the grid.

(II) Integrated Power Drive and Excitation Control for Simplified System Architecture

The built-in power amplifier circuit and excitation drive interface eliminate the need for additional power modules to drive servo valves and excitation systems, simplifying the design of the turbine control cabinet. In the control of a gas turbine in a combined cycle power plant:

- The module directly outputs ±10V DC signals to drive the gas turbine fuel servo valve (controlling fuel flow) and outputs PWM pulse signals to control the excitation regulator (adjusting the generator excitation current). This replaces the traditional multi-module solution of "DSP module + power amplifier module + excitation control module", reducing the control cabinet space occupation by 40% and the number of fault nodes by 50%.

- The 1.5x overload capacity of the power output channel can adapt to the instantaneous load impact of the fuel valve during gas turbine start-up and shutdown (overload current of 3A, duration of 50ms), avoiding start-up and shutdown failures caused by module damage.

(III) Redundant Design and Strong Anti-Interference for Enhanced Operational Reliability

The "1+1" module redundancy and reinforced isolation design ensure long-term stable operation in the harsh environment of turbine rooms. In the control of an auxiliary turbine in a nuclear power plant:

- Two DS200DSPCH1A modules operate in hot standby mode. The main module synchronizes control parameters to the standby module in real time. When the main module experiences computing anomalies due to electromagnetic interference (e.g., start-up and shutdown of nearby motors), the standby module takes over control within 100μs, ensuring no fluctuations in turbine speed and load and avoiding the impact of auxiliary system shutdown on nuclear power safety.

- The 2500V AC signal isolation resists the ground loop interference of the turbine shaft vibration sensor cable, with a vibration signal collection error of ≤0.1mm/s. This ensures that the module can accurately trigger shutdown protection when the shaft vibration exceeds the standard (e.g., ≥100μm), avoiding shaft system damage.

(IV) Turbine-Specific Diagnosis and Condition Monitoring for Reduced Maintenance Costs

The built-in turbine fault diagnosis library and condition monitoring function can provide early warning of potential faults, reducing unplanned downtime. In the control of an industrial drive turbine (e.g., a turbine for chemical plants):

- The module continuously monitors turbine parameters such as shaft vibration, shaft displacement, and oil pressure. When the shaft vibration rises slowly (from 50μm to 80μm), it proactively reports an "abnormal shaft vibration trend" alarm. Maintenance personnel can promptly check the bearing clearance, avoiding turbine shutdown caused by excessive shaft vibration (each day of shutdown results in a production loss of over 1 million yuan for the chemical plant).

- It uploads turbine operation data (speed, load, vibration) to the Proficy Historian database through the EtherNet/IP port to generate trend curves. Maintenance personnel can analyze operation patterns (e.g., speed fluctuations caused by increased oil temperature in summer) and optimize the maintenance cycle (e.g., adjusting the lubricating oil replacement cycle from 6 months to 8 months), reducing maintenance costs by 20%.

IV. Application Fields (Focusing on Turbine Control Scenarios)

(I) Power Industry: Turbine Control in Thermal/Combined Cycle Power Plants

- 300MW-600MW Thermal Power Unit Turbines: As the core control unit, the module collects signals from the turbine speed sensor (magnetoresistive sensor), shaft vibration sensor (eddy current sensor), and main steam pressure sensor (pressure transmitter). It controls the governor valve opening (driven by servo valve) and extraction valve (digital output), achieving stable operation at a speed of 3000rpm (regulation accuracy of ±0.3rpm) and a load response speed of ≤100ms, meeting the grid AGC frequency regulation requirements. The redundant configuration ensures continuous unit operation with an annual availability rate of ≥99.5%.

- Gas Turbines in Combined Cycle Power Plants: It controls the gas turbine fuel supply (driven by servo valve) and compressor inlet guide vane (IGV) opening, and collects gas turbine exhaust temperature (thermocouple signal) and combustion pulsation signal. It enables rapid load regulation (time from 50% to 100% load ≤5 minutes), adapting to the grid peak-shaving requirements.

(II) Industrial Drives: Turbine Control for Chemical/Metallurgical Applications

- Drive Turbines for Chemical Plants: Used to drive the agitator shafts of chemical reactors and compressors. The module controls the turbine speed (e.g., 5000rpm, regulation accuracy of ±1rpm) and collects lubricating oil pressure (4-20mA signal) and bearing temperature (RTD signal). When the oil pressure is lower than 0.1MPa, it triggers shutdown protection to avoid bearing wear. It communicates with the DCS via the Modbus RTU protocol to upload operation data, realizing the coordinated control of the chemical plant and the turbine.

- Turbines for Metallurgical Rolling Mills: Used to drive the main transmission system of rolling mills. The module controls the turbine speed (adapting to the rolling speed requirements of the rolling mill, with a speed regulation response time of ≤50ms) and collects the rolling mill load (torque sensor signal). When the load exceeds the limit, it quickly reduces the turbine speed to protect the rolling mill equipment, improving the rolling accuracy to ±0.05mm.

(III) New Energy: Turbine Control in Biomass/Waste Incineration Power Plants

- Turbines in Biomass Power Plants: Adapted to the unstable combustion characteristics of biomass fuels (e.g., straw, wood chips). The module stabilizes the turbine speed (3000rpm) through rapid PID regulation (sampling cycle of 0.1ms), collects steam parameters (temperature, pressure), and dynamically adjusts the governor valve opening to avoid large speed fluctuations caused by fuel variations (speed fluctuation ≤±5rpm).

- Turbines in Waste Incineration Power Plants: Targeting the corrosive gas environment generated by waste incineration, the module's PCB board adopts an anti-corrosion conformal coating. It collects the turbine condensed water quality signal (e.g., conductivity) and triggers drain valve control when the water quality exceeds the standard, protecting the turbine flow passage components and extending the unit's service life.

(IV) Ship Power: Marine Turbine Control

- Main Propulsion Turbines for Large Ships: The module adapts to the ship's Bumpy ride environment (anti-vibration acceleration ≥50m/s²), controls the turbine speed (e.g., 1500rpm, regulation accuracy of ±0.5rpm), and collects the propeller load signal to achieve stable control of the ship's speed. The redundant communication interfaces (optical fiber + Ethernet) ensure reliable communication with the ship's central control system, adapting to the strong electromagnetic environment at sea (e.g., radar interference).

- Power Generation Turbines for Ships: Used to supply power to ships. The module controls the turbine speed (3600rpm), adapts to the load fluctuations of the ship's power grid (e.g., start-up and shutdown of radar and communication equipment), and has a load regulation response time of ≤200ms, ensuring the stability of the ship's power grid voltage (±2% of rated voltage).