Description

GE IS230TDBTH6A

I. Product Overview

The GE IS230TDBTH6A is a high-performance industrial-grade temperature control and monitoring module launched by General Electric (GE). It belongs to the core I/O component family of GE's Mark VIe Distributed Control System (DCS) and Speedtronic turbine control system. Its core positioning is to achieve precise collection, real-time monitoring, and closed-loop control of multi-channel temperature parameters in industrial production processes. Through high-precision temperature measurement circuits, flexible control algorithms, and strong system compatibility, it realizes temperature management of key equipment such as turbines, boilers, and chemical reactors, providing core data support for the safe, stable operation and process optimization of industrial production.

The application scenarios of this module extensively cover fields with strict requirements for temperature measurement accuracy and control reliability, including power energy (temperature monitoring of turbine casings in thermal power units, temperature collection of boiler tube walls), petroleum and chemical industry (closed-loop temperature control of reactors, temperature monitoring of pipeline media), metallurgy and steel (temperature control of blast furnace hot stoves, temperature monitoring of rolling mill rolls), and heavy machinery (temperature monitoring of engine blocks, oil temperature control of hydraulic systems). As a dedicated module for GE's high-end control systems, it not only has excellent temperature collection performance but also can achieve seamless collaboration with the system, supporting the rapid deployment of complex control logic. It is a key component for building highly reliable industrial temperature control systems.

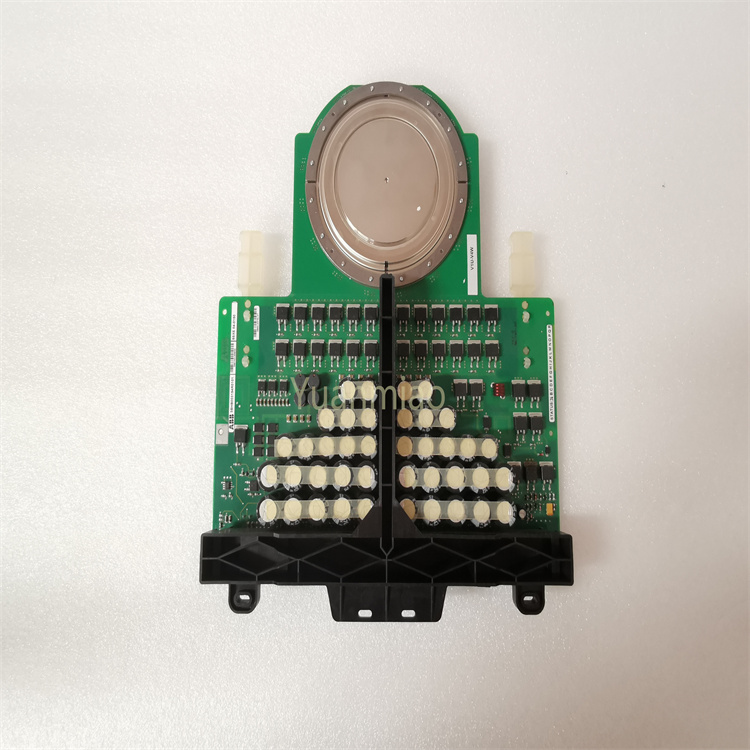

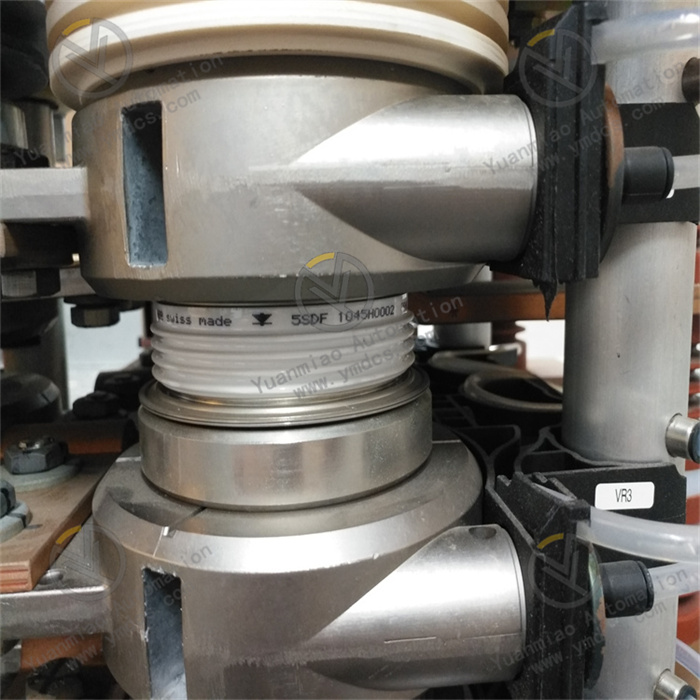

In terms of hardware architecture and system compatibility, the GE IS230TDBTH6A adopts a standardized modular design, which can be seamlessly integrated into the I/O racks (such as IC695 racks) of GE's Mark VIe control system and Speedtronic turbine control cabinets, occupying one standard I/O module slot. It realizes high-speed data interaction with the system controller through the backplane bus. The module is compatible with GE CIMPLICITY HMI and iFIX monitoring software, supporting configuration of temperature measurement ranges, control algorithm parameters, and alarm thresholds through a graphical interface, enabling system integration without underlying code development. Relying on industrial-grade reinforced design, the module can adapt to industrial on-site environments with high temperature, high humidity, dust, and strong electromagnetic interference, ensuring continuous stability of temperature collection and control.

II. Technical Parameters

III. Functional Features

1. Multi-Channel High-Precision Measurement, Adapting to Diverse Temperature Scenarios

The GE IS230TDBTH6A is equipped with 8 independent temperature measurement channels, supporting the connection of multiple types of sensors including thermocouples (8 types such as J/K/T) and RTDs (4 types such as Pt100). It can adapt to temperature measurement needs of different ranges without additional signal conversion modules, such as simultaneous monitoring of high temperatures of turbine casings (up to over 1000℃) and low temperatures of hydraulic systems (below -50℃). The 24-bit A/D conversion technology enables a temperature resolution of 0.01℃. The RTD measurement accuracy reaches ±0.05℃ within the range of -50℃~200℃, and the thermocouple accuracy reaches ±0.2℃ within 100℃~1000℃, which is much higher than that of ordinary industrial-grade temperature modules. The 8 channels support synchronous sampling, with a maximum single-channel sampling rate of 10Hz, which can capture dynamic temperature changes in real time and provide accurate data support for scenarios with rapid temperature fluctuations (such as the heating stage of chemical reactors).

2. Multi-Algorithm Closed-Loop Control, Excellent Control Accuracy

The module supports simultaneous closed-loop temperature control of 4 channels, with 4 core built-in algorithms: standard PID, PID auto-tuning, fuzzy PID, and feedforward-feedback control, which can be flexibly selected according to different process characteristics. The PID auto-tuning function can automatically identify the dynamic characteristics of the controlled object (such as lag time and gain), intelligently optimize PID parameters, and avoid the complexity and errors of manual debugging. The fuzzy PID algorithm has better control effects for controlled objects with large lag and nonlinearity (such as boiler temperature control), which can effectively suppress overshoot and oscillation. The feedforward-feedback control can adjust the output in advance based on process disturbances (such as changes in feed quantity), improving control accuracy. The control response time is ≤100ms, which can quickly adjust the output when a temperature deviation occurs, stabilizing the temperature within the range of ±0.1℃ of the set value, meeting the needs of high-precision temperature control (such as semiconductor manufacturing and precision chemical engineering).

3. Diverse Outputs and Alarms, Timely Control Response

The module is equipped with 4-channel 4~20mA analog outputs and 2-channel relay outputs, realizing multi-form feedback of temperature control and alarms. The analog output can directly drive actuators such as control valves and heaters, with an output accuracy of ±0.03% FS, ensuring accurate transmission of control signals. The relay output can be configured as temperature over-limit alarm (such as high-temperature triggering shutdown), sensor fault alarm, or control logic linkage (such as low-temperature starting heater), directly driving alarms, indicator lights, or contactors to achieve local rapid response. It supports 4 core alarm types: high-temperature, low-temperature, temperature deviation, and sensor fault. Alarm thresholds can be accurately set through configuration software, and alarm signals are simultaneously uploaded to the controller and upper-level system through the backplane bus, ensuring timely detection and handling of abnormal situations.

4. Redundancy Configuration and Fault Isolation, Stable and Reliable Operation

It supports 1:1 module hot redundancy configuration. The master and standby modules realize real-time data synchronization through a dedicated redundant communication link, including measurement data, control parameters, output status, and fault information, with a synchronization delay of ≤1ms. During normal operation, the master module performs measurement and control functions, while the standby module monitors the status of the master module in real time and synchronizes data. When the master module experiences power failure, channel abnormality, or communication interruption, the standby module can automatically switch without disturbance within 15ms. During the switching process, there is no fluctuation in control output and no temperature deviation, ensuring uninterrupted temperature control of key equipment such as turbines and boilers. The module has channel-level fault isolation capability. When a sensor open/short circuit or measurement abnormality occurs in a single channel, it automatically isolates the faulty channel and triggers an alarm, without affecting the measurement and control of other channels, improving the system's fault tolerance.

5. Full-Dimensional Fault Diagnosis, Efficient and Convenient Operation and Maintenance

It has a fault diagnosis coverage rate of 99.5%, integrating triple diagnosis mechanisms at the sensor level, channel level, and module level. The sensor level can automatically identify open circuits, short circuits, reverse connections, and aging faults (judged by the stability of measured signals). The channel level monitors channel health through signal verification and A/D conversion accuracy detection. The module level monitors hardware status through power supply monitoring and communication link detection. It can accurately identify more than 20 types of faults and generate standardized fault codes (such as sensor open circuit code E01, A/D fault code E08). When a fault occurs, the local LED indicator lights alarm in layers (yellow light flashes for channel faults, red light stays on for module faults), and at the same time, fault information is uploaded to the upper-level system, clearly indicating the fault location, type, and handling suggestions (such as "Channel 3 sensor open circuit, please check the wiring"). It supports online calibration and remote diagnosis. Operation and maintenance personnel can complete calibration and fault troubleshooting through GE CIMPLICITY software without shutting down the system.

6. In-Depth System Compatibility and Flexible Integration, Efficient Deployment

As a dedicated module for GE Mark VIe and Speedtronic systems, the IS230TDBTH6A adopts a standardized interface design, which can be seamlessly integrated into the corresponding system racks. It realizes high-speed data interaction with the controller through the backplane bus, with a data transmission rate of ≥100Mbps, ensuring real-time transmission of measurement data and control commands. It is compatible with GE CIMPLICITY HMI and iFIX monitoring software, supporting configuration of sensor types, selection of control algorithms, parameter setting, and alarm threshold adjustment through a graphical interface. It has built-in common process control templates (such as turbine temperature control template and boiler control template), and the integration and debugging cycle is shortened by more than 60% compared with traditional modules. At the same time, it supports communication with third-party DCS systems through the Modbus TCP protocol and has standard communication interfaces, which can be flexibly integrated into non-GE control systems, improving the flexibility of system integration.

IV. Working Principle

The GE IS230TDBTH6A realizes high-precision temperature measurement and control through the collaboration of hardware circuits and software algorithms, based on the core workflow of "signal collection - data processing - control calculation - output feedback - fault diagnosis". The specific working mechanism is as follows:

1. Temperature Signal Collection and Preprocessing

Signals from on-site temperature sensors (thermocouples/RTDs) are connected through the module's input terminals and first enter the signal conditioning unit. For thermocouple signals, the conditioning unit performs cold-junction compensation (using a high-precision temperature sensor to measure the internal temperature of the module in real time to compensate for the impact of ambient temperature on measurement), filtering and noise reduction, and linearization processing. For RTD signals, the conditioning unit provides constant current excitation (ensuring the excitation current is stable at 1mA or 5mA), collects the voltage across the RTD, and performs linearization correction. The preprocessed signals are sent to the 24-bit A/D conversion unit, converted into digital signals, and stored in the data register. At the same time, the signal monitoring unit monitors the amplitude and stability of the signals in real time, and immediately triggers fault diagnosis if an abnormality (such as open circuit or short circuit) is detected.

2. Control Algorithm Calculation

3. Redundancy Synchronization and Switching

4. Output Feedback and Fault Handling