Description

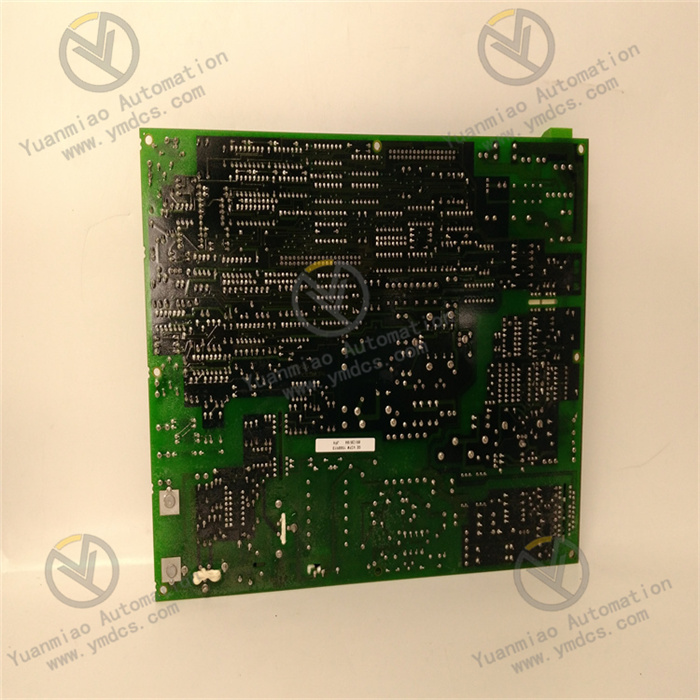

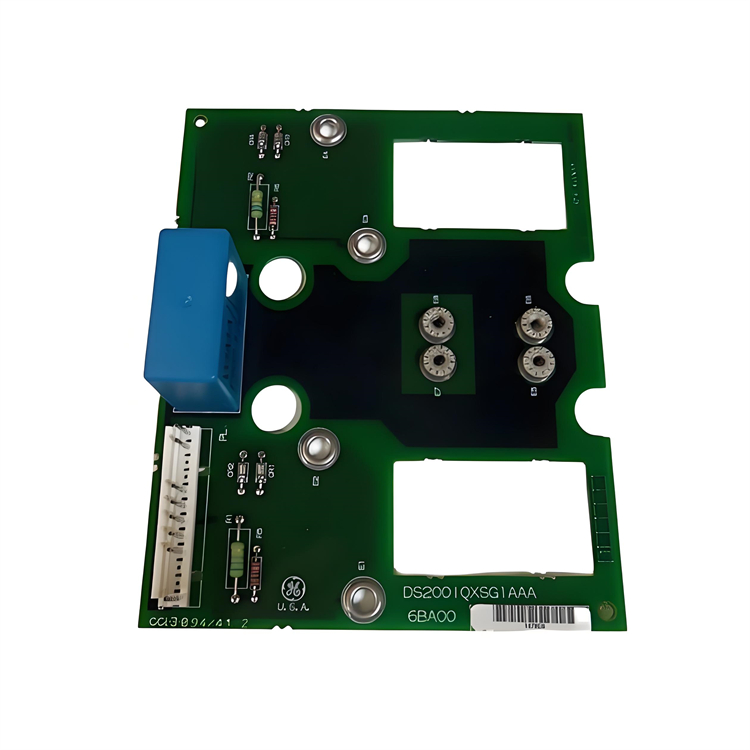

GE 531X303MCPBBG1

I. Product Overview

The GE 531X303MCPBBG1 is a logic control module that belongs to the core component family of GE industrial control systems. It is widely used in the control scenarios of key industrial equipment such as steam turbines, gas turbines, generator sets, and large compressors, and plays a core role in industries with extremely high requirements for control reliability, including power generation, petrochemicals, metallurgy, and energy. Its core functions include receiving signals from on-site sensors, actuators, and upper-level systems, completing signal processing, interlock control, fault judgment, and command output through built-in logic operation programs, so as to realize precise regulation of the operating status of industrial equipment, safety protection, and data interaction. It is a key core component for building highly reliable industrial automation control systems.

II. Technical Parameters

| Parameter Category | Parameter Name | Specific Parameters | Unit |

|---|---|---|---|

| Basic Parameters | Model Number | GE 531X303MCPBBG1 | - |

| Product Type | Multi-channel Logic Control and Signal Processing Module | - | |

| System Compatibility | Mainstream GE industrial control systems such as GE Mark VIe, Speedtronic, GE Fanuc | - | |

| Compatible Rack | GE standard industrial control rack (e.g., IC697 rack), occupying 1 standard control slot | - | |

| Overall Dimensions (L×W×H) | 175×110×260 | mm | |

| Installation Method | Rack slot embedded installation with mechanical latch positioning and anti-loosening structure | - | |

| I/O Parameters | Digital Input Channels | 16 independent channels, supporting dry contact/wet contact input, input voltage DC 24V | Channel(s) |

| Digital Output Channels | 12 independent channels, relay output (normally open/normally closed configurable), contact rating AC 250V/5A | Channel(s) | |

| Analog Input Channels | 8 independent channels, supporting 4~20mA DC/0~10V DC, input impedance ≥10kΩ | Channel(s) | |

| Analog Output Channels | 6 independent channels, output 4~20mA DC, load capacity ≤500Ω | Channel(s) | |

| Input Signal Response Time | Digital: ≤1ms, Analog: ≤5ms | ms | |

| Output Command Execution Delay | ≤3ms (from logic judgment to output action) | ms | |

| Core Control Parameters | Core Processor | GE proprietary 32-bit industrial control processor, main frequency 500MHz | - |

| Logic Operation Capability | Supports Boolean logic, sequential logic, arithmetic operations, operation cycle ≤1ms | ms | |

| Program Storage Capacity | Built-in 16MB Flash memory, supporting program solidification and online modification | MB | |

| Data Storage Capacity | 8MB RAM, capable of storing 100,000 pieces of historical data and fault records | MB | |

| Redundancy Support | Supports hot redundancy configuration, dual modules operating synchronously, fault switching time ≤5ms | ms | |

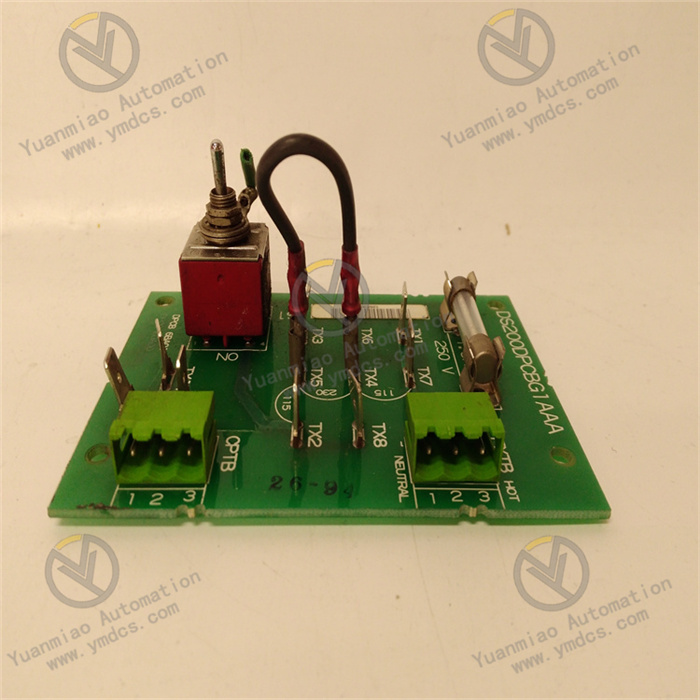

| Electrical & Communication Parameters | Power Supply Voltage | Provided by system rack bus: DC 24V±10%, supporting redundant power input | V |

| Maximum Power Consumption | ≤15W (under full configuration operation) | W | |

| Isolation Performance | Input-output: 2500VAC/1min; Input-power: 2000VAC/1min; Inter-channel: 1500VAC/1min | VAC/min | |

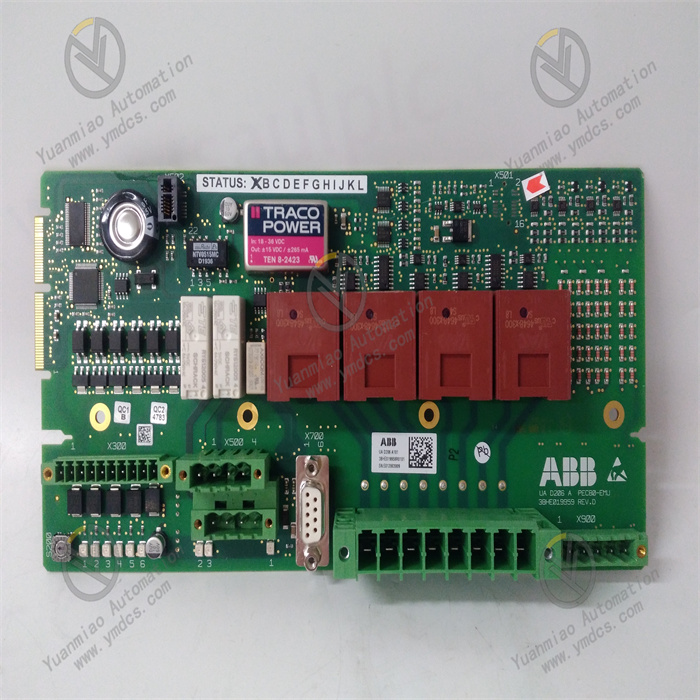

| Communication Interfaces | 2 RS485 (Modbus RTU protocol), 1 Ethernet (TCP/IP, supporting GE Proficy communication protocol) | - | |

| Environmental Parameters | Operating Temperature Range | -20~65℃ (standard operating range); -40~70℃ (extended operating range, continuous operation ≤72 hours) | ℃ |

| Storage Temperature Range | -40~85℃, no condensation | ℃ | |

| Relative Humidity | 5%~95% (no condensation, complying with IEC 60068-2-3 standard) | % | |

| Electromagnetic Interference Resistance | Complying with IEC 61000-4 series standards, ESD ±15kV (air discharge)/±8kV (contact discharge), RF interference suppression ≥50dB | - |

III. Functional Features

- In-depth GE System Compatibility & Efficient Integration: The module adopts a unified hardware interface and communication protocol of GE industrial control systems. It can be directly inserted into standard racks of systems such as Mark VIe and Speedtronic. After power-on, it automatically establishes communication connections with the system controller, power module, and I/O modules, realizing "plug-and-play" integration. It supports full graphical programming with GE Proficy configuration software, enabling quick completion of logic program writing, I/O channel configuration, alarm threshold setting, and communication parameter configuration without additional driver development. The data interaction delay with other modules in the system is ≤1ms, ensuring real-time synchronization of control commands and monitoring data, and significantly shortening the system integration and debugging cycle.

- Multi-channel I/O Integration & Comprehensive Control Capability: It integrates 16 digital input channels, 12 digital output channels, 8 analog input channels, and 6 analog output channels. It can simultaneously connect signals from on-site sensors (e.g., temperature, pressure, vibration sensors), actuators (e.g., solenoid valves, control valves), and upper-level systems, realizing comprehensive collection of equipment operating parameters and accurate output of control commands. Digital channels support flexible switching between dry/wet contacts, and analog channels are compatible with 4~20mA and 0~10V standard signals, adapting to different types of on-site equipment without additional signal conversion modules, thus improving system integration.

- High-performance Logic Operation & Rapid Accurate Response: Equipped with a GE proprietary 32-bit industrial control processor with a main frequency of 500MHz, it supports complex control algorithms such as Boolean logic, sequential logic, and arithmetic operations, with an operation cycle of ≤1ms. It can quickly process multi-channel input signals and execute logic judgments. The input signal response time is ≤1ms, and the output command execution delay is ≤3ms, which can timely capture changes in equipment operating status and output control commands. It has strong adaptability to scenarios with extremely high real-time requirements, such as steam turbine speed regulation and compressor pressure control. It supports programming of complex control strategies, such as PID regulation and fuzzy control, to meet the precise control needs of different equipment.

- Hot Redundancy Configuration Support & Safe Reliable Operation: It supports dual-module hot redundancy configuration. The two modules synchronously receive input signals, execute logic operations, and output control commands. When the main module fails, the standby module can automatically switch to take over the control task within ≤5ms, with no control interruption during the switching process, ensuring continuous and stable operation of the equipment. It is suitable for key scenarios that do not allow shutdown, such as generator sets and large chemical reaction devices. The module has built-in fault diagnosis and fault-tolerance mechanisms, which can perform real-time monitoring on core components such as processors, memories, and I/O channels. When a fault is detected, it promptly triggers an alarm and switches to the redundant module, improving system reliability.

- Comprehensive Alarm & Protection & Strict Safety Shielding: It has multi-level alarm and interlock protection functions. Various fault alarm thresholds (such as over-temperature, over-pressure, and over-load) can be set according to equipment operation procedures. When the monitored parameter reaches the alarm threshold, it immediately triggers the local LED indicator alarm and uploads alarm information to the upper-level system; when it reaches the interlock threshold, it quickly outputs interlock control commands (such as emergency shutdown and feed cutoff) to prevent fault expansion. It supports storage and traceability of historical alarm data, which can record information such as alarm time, alarm parameter value, and fault type, providing a reliable basis for fault troubleshooting. The alarm logic supports delay anti-shake configuration (0~20s), effectively avoiding false alarms caused by transient interference.

- Multiple Communication Interfaces & Flexible Data Interaction: Equipped with 2 RS485 and 1 Ethernet communication interfaces, it supports mainstream industrial communication protocols such as Modbus RTU and GE Proficy, enabling seamless data interaction with upper-level monitoring systems, data collectors, HMI (Human-Machine Interface) devices, etc. Remote monitoring and programming can be realized through the Ethernet interface. Operation and maintenance personnel can complete module program modification, parameter configuration, and fault diagnosis in the central control room without on-site operations, improving operation and maintenance efficiency. It supports multi-module networking communication, which can build a distributed control system to adapt to the collaborative control needs of multiple devices in large industrial sites.

- Multiple Anti-interference & Isolation & Adaptation to Harsh Environments: It adopts a triple electrical isolation design of "input-output", "input-power", and "inter-channel", with a maximum isolation voltage of 2500VAC/1min, effectively blocking interference from on-site ground loops, power fluctuations, and equipment electromagnetic radiation to the module. It has built-in EMC (Electromagnetic Compatibility) filter circuits and surge suppression components, which can withstand ±15kV ESD (Electrostatic Discharge) shock and ±2kV pulse group interference. Complying with IEC 61000-4 series electromagnetic interference resistance tests, it can still operate stably in strong interference environments such as high-voltage frequency converters and high-power motors, with RF (Radio Frequency) interference suppression ≥50dB. The sensor input and output interfaces adopt shielding design, and when used with dedicated shielded cables, the anti-interference performance is further improved.

- Industrial-grade Reinforced Design & Strong Environmental Adaptability: It adopts industrial-grade high-reliability components and an integrated metal shell design. The shell is made of high thermal conductivity aluminum alloy, with an optimized internal heat dissipation structure that can quickly dissipate heat generated by core components, ensuring stable operation within the standard temperature range of -20~65℃. It has passed IEC 60068-2-6 vibration test (5~150Hz, 3g acceleration) and IEC 60068-2-27 shock test (15g acceleration, 11ms duration), and can adapt to vibration during industrial equipment operation and shock during transportation and installation. The module has an IP20 protection rating, equipped with a dust-proof panel and waterproof aviation connectors, which can effectively block dust and oil pollution in industrial sites, adapting to harsh operating environments with heavy dust, high temperature, and strong vibration.

- Convenient Operation & Maintenance & Diagnosis & Reduced Maintenance Costs: It supports online programming and debugging. Through GE Proficy configuration software, real-time monitoring of module operation status, I/O channel signals, and logic operation processes can be realized, and program modification and parameter calibration can be completed without shutdown. It has a built-in comprehensive self-diagnosis function, which can perform full fault diagnosis on power supply, processor, memory, I/O channels, communication interfaces, etc. The diagnosis information is intuitively displayed through local LED indicators and uploaded to the upper-level system, supporting fault code query to help operation and maintenance personnel quickly locate fault points. The module has built-in program and data backup functions, and backup data can be exported through communication interfaces to avoid program loss and reduce maintenance costs.

IV. Working Principle

As the core logic control unit of the GE industrial control system, the GE 531X303MCPBBG1 module takes "signal collection - logic operation - command output - alarm protection - self-diagnosis" as its core workflow to realize precise control and safety protection of key industrial equipment. The specific working mechanism is as follows:

- Module Initialization and Configuration Loading: After the module is installed in the system rack and powered on, it automatically starts the initialization process. First, it performs a hardware self-test, sequentially checking the integrity of the connection between the processor, memory, I/O channels, communication interfaces, and the rack backplane; after passing the self-test, it establishes communication with the system controller through the internal rack bus, receives and loads preset configuration parameters and control programs, including I/O channel configuration, logic operation rules, alarm thresholds, communication parameters, and redundancy configuration information. After the initialization is completed, the module feeds back a "ready" signal to the controller, the operation indicator light remains on, and it enters the normal working mode; if the self-test fails or the configuration parameters fail to load, a fault alarm is triggered immediately, the fault code is uploaded, and the fault indicator light is turned on.

- Multi-type Signal Collection and Preprocessing: The module collects on-site signals through digital and analog input channels: the digital channels collect discrete signals such as solenoid valve status and limit switch status, which are converted into standard digital level signals after photoelectric isolation; the analog channels collect continuous signals such as temperature, pressure, and speed, which are amplified and filtered by the signal conditioning circuit, then converted into digital signals by a 16-bit AD converter. All collected signals are sent to the data buffer after preprocessing to ensure the integrity and stability of the signals. At the same time, external interference is blocked through the isolation circuit to protect the safety of the internal circuit of the module.

- Logic Operation and Control Decision-making: The core processor reads the preprocessed input signals from the data buffer and performs operation processing according to the loaded control programs and logic operation rules (such as Boolean logic, PID regulation, sequential control, etc.). Based on the input signal status and preset control strategies, the processor calculates and generates control commands, such as adjusting the opening of the control valve, controlling the start and stop of the motor, and switching the valve status. In the redundancy configuration mode, the main and standby modules synchronously perform signal collection and logic operations, and compare the operation results in real time to ensure the consistency of output commands and prepare for fault switching. The intermediate data and results during the operation process are stored in the built-in RAM for subsequent calling and monitoring.

- Control Command Output and Execution: The core processor sends the calculated control commands to the output channels: the digital output channels control the action of the relay through the relay drive circuit, outputting discrete control signals to the actuator; the analog output channels convert the digital control signals into 4~20mA or 0~10V standard analog signals through the DA converter, outputting them to executive equipment such as control valves and frequency converters. During the output process, the module performs real-time monitoring on the output signals to ensure the accurate execution of the commands. If a fault in the output channel is detected, it immediately switches to the redundant channel (in the case of redundancy configuration) and triggers an alarm.

- Alarm Judgment and Safety Protection: The processor compares the collected input signals with the preset alarm thresholds in real time to judge whether there is an abnormality in the equipment. When the monitored value reaches the warning threshold, the module turns on the local warning indicator light and uploads warning information (including alarm type, parameter value, and time stamp) to the upper-level system through the communication interface; when it reaches the danger threshold, it immediately outputs interlock control commands (such as emergency shutdown), and at the same time triggers an audible and visual alarm and uploads danger alarm information. The alarm information is stored in the Flash memory in real time and can be saved for a long time for subsequent traceability. It supports the alarm reset function; after the fault is eliminated, the alarm status can be reset through the local button or the upper-level system command.

- Real-time Communication and Data Interaction: Through RS485 and Ethernet communication interfaces, the module uploads data such as input signal status, output commands, operation results, alarm information, and module operation status to upper-level monitoring systems, HMIs, and other devices in real time; at the same time, it receives control commands, parameter modification commands, and program update commands issued by the upper-level system, realizing remote monitoring and operation and maintenance. In the multi-module networking scenario, the module realizes data sharing with other modules through communication interfaces and collaboratively completes complex control tasks, ensuring the synchronization and coordination of the entire control system.

- Full-dimensional Self-diagnosis and Fault Handling: During operation, the module continuously performs full-dimensional self-diagnosis, including power fault diagnosis (monitoring the stability of the power supply voltage), hardware fault diagnosis (detecting the status of components such as the processor, memory, and I/O channels), software fault diagnosis (verifying the integrity of the control program), and communication fault diagnosis (monitoring the connection status of the communication link). When a fault is diagnosed, the module immediately performs corresponding processing: in the non-redundancy configuration, it turns on the fault indicator light and uploads fault information; in the redundancy configuration, it triggers the switch between the main and standby modules to ensure no interruption of control. At the same time, it records the fault details (fault type, occurrence time, fault location) to provide a precise basis for operation and maintenance personnel to troubleshoot faults.