Description

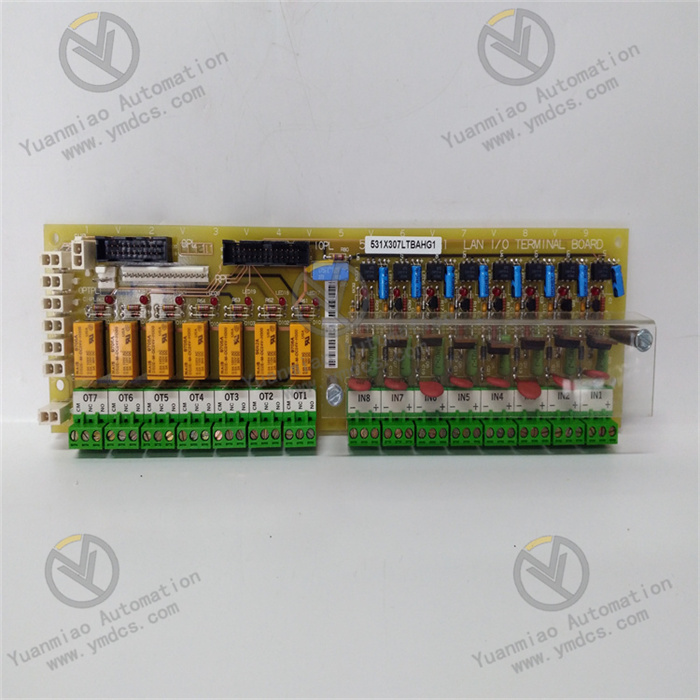

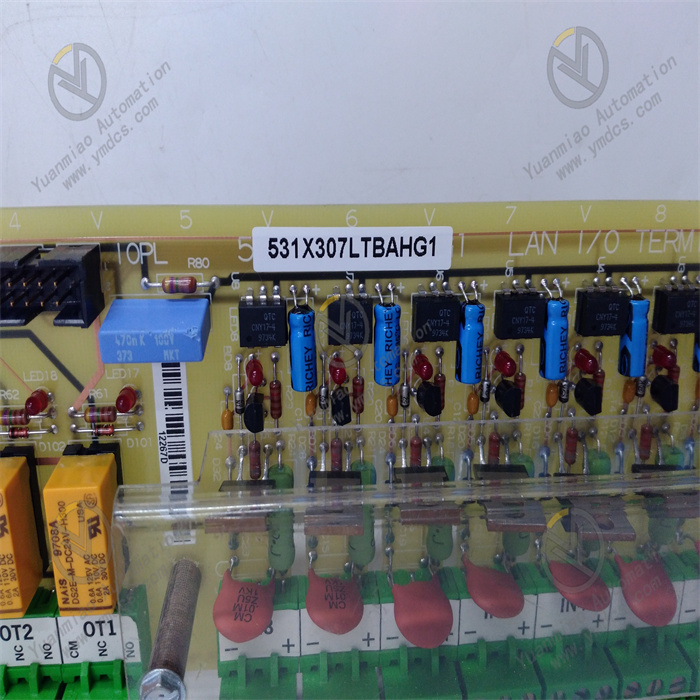

GE 531X307LTBAHG1

The GE 531X307LTBAHG1 is a signal I/O module belonging to classic industrial control systems such as GE Mark VIe or Fanuc Series 90-30. Its core positioning is "the core for multi-type signal acquisition, logic operation, and control command execution in embedded control systems under harsh industrial environments". It mainly serves fields with extremely high requirements for signal acquisition accuracy, control response speed, and environmental adaptability, including power generation equipment monitoring (e.g., steam turbines, gas turbines), metallurgical rolling mill control, chemical process regulation, and rail transit equipment signal processing. It undertakes the full-process key tasks of "on-site analog/digital signal acquisition - signal conditioning and conversion - logic operation and interlock control - control command output - equipment status feedback".

With core advantages of "mixed-signal compatible acquisition + industrial-grade high-reliability hardware + wide-temperature and harsh-environment-resistant design + full-system adaptation", this module has irreplaceable value in scenarios such as the upgrading of old industrial control systems (e.g., replacing traditional discrete I/O components) and the construction of new embedded control nodes (e.g., distributed control units). Its core function is to solve the three major pain points in industrial control: "difficulty in multi-type signal compatibility", "signal distortion in complex environments", and "control command response delay". Through high-precision signal conditioning circuits, standardized system interfaces, and enhanced protection design, it realizes accurate on-site signal acquisition (analog accuracy ≤ ±0.1% F.S., digital response ≤ 1ms) and efficient control (output response ≤ 5ms), avoiding production interruptions caused by inaccurate signal processing or control delays (the loss of a single interruption can reach hundreds of thousands of yuan) and ensuring the continuous and stable operation of industrial systems.

- One-stop processing of multi-type signals: Integrates analog (4-20mA, 0-10V) and digital (dry/wet contact) acquisition channels, enabling simultaneous connection to different types of peripherals such as temperature sensors, pressure transmitters, proximity switches, and photoelectric sensors. No additional independent acquisition modules are required, reducing the number of system components by 50% compared with discrete solutions, and lowering integration costs and failure rates. For example, in chemical reactor control, it can simultaneously collect analog signals of reaction temperature (4-20mA) and pressure (0-10V), as well as digital signals such as valve switching and motor operation status, realizing "temperature + pressure + equipment status" coordinated control.

Flexible signal conditioning and adaptation: Analog channels support single-ended/differential switching; in differential mode, the common-mode rejection ratio is ≥ 80dB, which can effectively suppress interference signals generated by long-distance wiring (≤ 100m). It supports custom signal ranges (configured via debugging software) and is compatible with sensors of different specifications (e.g., 0-5V liquid level sensors, 2-10mA flow sensors). Diverse acquisition needs can be met without replacing the module, improving system adaptation flexibility.

- Wide-temperature and anti-interference design: Core components adopt wide-temperature models (-40℃~+85℃); the circuit board is coated with nano-level three-proof paint (waterproof, dustproof, anti-corrosive), enabling stable operation in scenarios such as outdoor power control cabinets in Northeast China (winter temperature -35℃), coastal chemical workshops (high humidity and high salt spray), and metallurgical high-temperature workshops (ambient temperature 65℃). The annual failure rate of the module is ≤ 0.3%. The power module is equipped with an EMC filter circuit (common-mode rejection ratio ≥ 75dB); when installed near high-power frequency converters (above 200kW), the analog acquisition error is still ≤ 0.2% F.S., and there is no misjudgment of digital signals.

Enhanced isolation and protection: All signal channels adopt 2500Vrms electrical isolation to avoid crosstalk between different signals and ground loop interference (e.g., signal distortion caused by equipment ground potential difference). Digital output relays adopt sealed packaging (protection class IP65), and contacts are gold-plated (thickness ≥ 0.5μm). In the control of mining equipment with heavy dust, the contact oxidation rate is ≤ 0.1μm/year, ensuring long-term reliable operation.

- Fast signal response and operation: The analog acquisition accuracy reaches ±0.1% F.S., which can accurately capture small signal changes (e.g., 0.5℃ fluctuation of steam turbine bearing temperature). The digital input response time is ≤ 1ms, which can quickly identify emergency signals such as emergency stop buttons and equipment faults. Combined with the 10ms operation cycle of the 16-bit microprocessor, the total delay of control commands from signal acquisition to output execution is ≤ 15ms, meeting the real-time requirements of industrial control (e.g., rolling mill thickness control, elevator safety protection).

Intelligent logic and interlock control: Built-in rich logic operation functions, supporting multi-signal interlock (up to 8-channel input signal linkage), which can realize "condition trigger - command output" automatic control (e.g., "temperature ≥ 100℃ + pressure ≥ 0.8MPa" interlock to close the feed valve). It does not rely on the computing power of the upper computer, reducing system communication load and delay risks. At the same time, it supports analog threshold alarms (e.g., liquid level exceeding the upper limit triggers an audible and visual alarm), realizing rapid local response and improving control safety.

- Cross-system compatibility and upgrading: Perfectly compatible with GE-series control systems such as GE Mark VIe and Fanuc 90-30, supporting GE Proficy Machine Edition programming software. Module function blocks (AI, DI, DO function blocks) can be directly called, shortening the programming cycle from 3 days (traditional solution) to 1 day. It is compatible with GE old-generation I/O modules (e.g., 531X305 series), enabling direct replacement of old modules while retaining the original wiring and programs, reducing the upgrade cost by 60%. In addition, it supports interconnection with third-party systems such as Siemens and Rockwell via PROFIBUS DP bus, solving the problem of cross-brand system integration.

Visual operation & maintenance and fault diagnosis: 33 status indicators are installed on the front panel, allowing on-site personnel to quickly judge the signal status through the indicators (e.g., "analog input indicator not on" indicates a sensor or channel fault; "output indicator on but load not working" indicates a relay or load problem). The debugging serial port supports reading real-time data (acquisition values, output status, fault logs) via terminal software. The built-in fault log can record the latest 50 fault information (including fault type and occurrence time), shortening the fault location time from an average of 2 hours to 30 minutes and reducing shutdown losses.

![]()