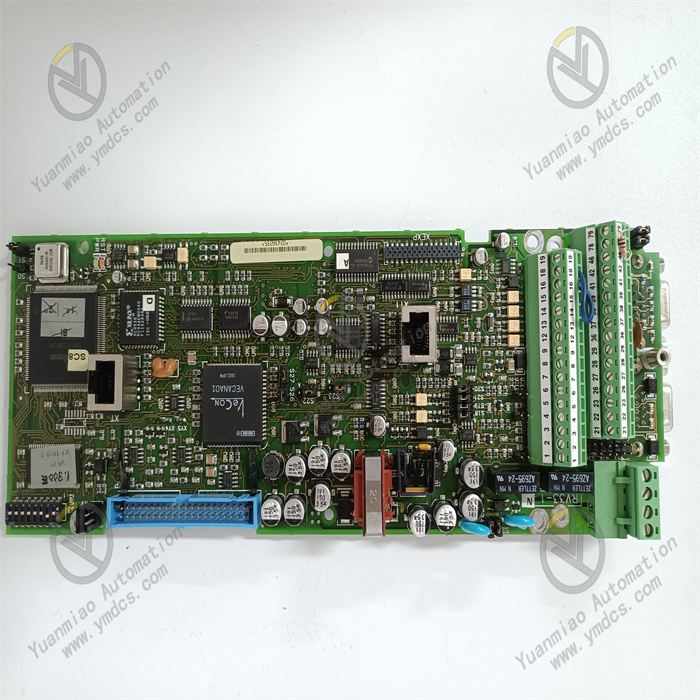

Description

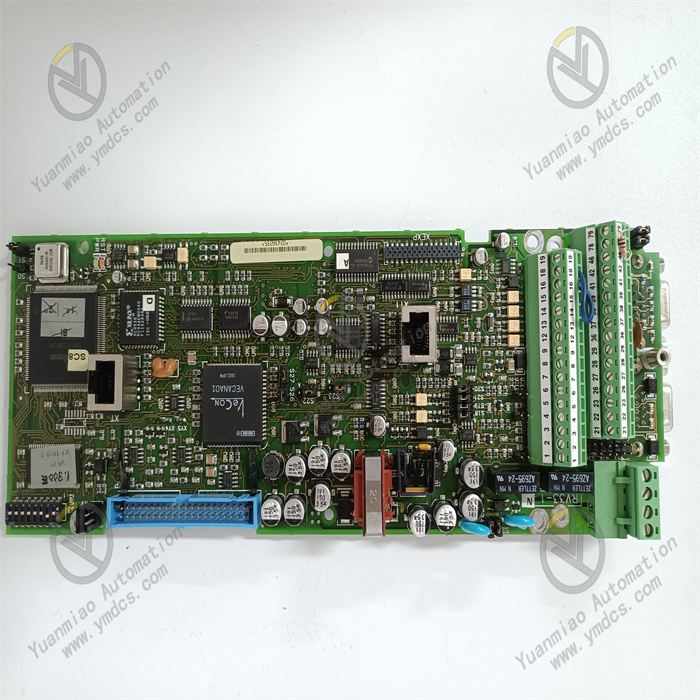

GE RV33-1

The GE RV33-1 is a drive control power board specifically designed for motor and driver systems. Its core positioning is to provide an integrated power solution that combines "stable power supply + precise control + safety protection". As a key core component connecting the main power grid to industrial drive equipment (such as servo drives and variable-frequency drives), its essential function is to convert three-phase AC input into stable electrical energy required by the drives through high-efficiency power conversion technology. Meanwhile, it integrates control functions for speed, position, and torque, directly participating in the adjustment and optimization of equipment operating parameters to ensure that motors and drives operate efficiently and safely in harsh industrial environments.

This product adopts a modular and compact design, compatible with GE's mainstream drive systems. It features industrial-grade characteristics including wide-temperature operation (-40°C to 85°C), high protection level (IP65), and high reliability, and has passed stringent electromagnetic compatibility and safety certifications. Leveraging its performance advantages of 33A high output current and 95% ultra-high conversion efficiency, it is widely used in scenarios such as manufacturing automation production lines, power transmission systems, and oil and gas control equipment. It serves as the core hub for ensuring "power supply - precise control - safe operation" in industrial drive systems.

- Input Voltage: Supports dual-specification input of three-phase AC 380V or 480V, compatible with mainstream industrial high-voltage power supply systems, allowing direct connection without additional voltage conversion equipment.

- Output Capacity: Maximum output current up to 33A, corresponding to a maximum power of 792W, which can meet the power demand of medium and high-power drives (e.g., servo motor drives below 5.5kW).

- Conversion Efficiency: Power conversion efficiency is as high as 95%, far exceeding the industry average (approximately 85-90%), significantly reducing electrical energy loss and suitable for green and energy-saving production scenarios.

- Integrated Control Functions: Natively supports three core modes: speed control, position control, and torque control. Through the drive system, it can achieve stepless speed adjustment of 0-3000rpm, ±0.1mm positioning accuracy control, and 0-100% torque output adjustment.

- Response Speed: The control signal response delay is ≤5ms, enabling rapid adaptation to load fluctuations (such as instantaneous current changes in welding equipment and emergency start-stop operations of robots).

- Appearance Design: Adopts a modular and thin structure with a thickness of ≤30mm (referring to the general dimensions of the series), suitable for dense layout in control cabinets and enabling seamless integrated installation with GE drives.

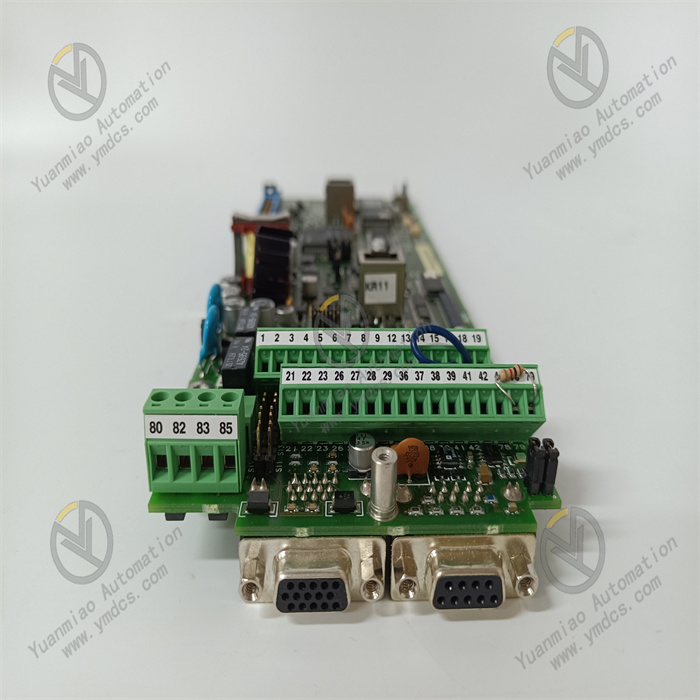

- Installation Methods: Supports two installation modes: DIN rail mounting and panel embedded mounting. The mounting hole spacing is compatible with industrial standard spacing, allowing a single person to complete the installation operation.

- Operating Temperature: Features an ultra-wide temperature operation range of -40°C to 85°C, which can not only adapt to the low-temperature environment of outdoor control cabinets in northern winters (e.g., power supplies for traffic monitoring equipment) but also withstand high-temperature working conditions in metallurgical workshops and welding stations.

- Protection Level: Meets the IP65 protection standard, providing complete dustproof protection and resistance to low-pressure water jets. It can be directly installed in on-site workshop cabinets or outdoor equipment cabinets without additional protection, eliminating the need for a dedicated sealed cabinet.

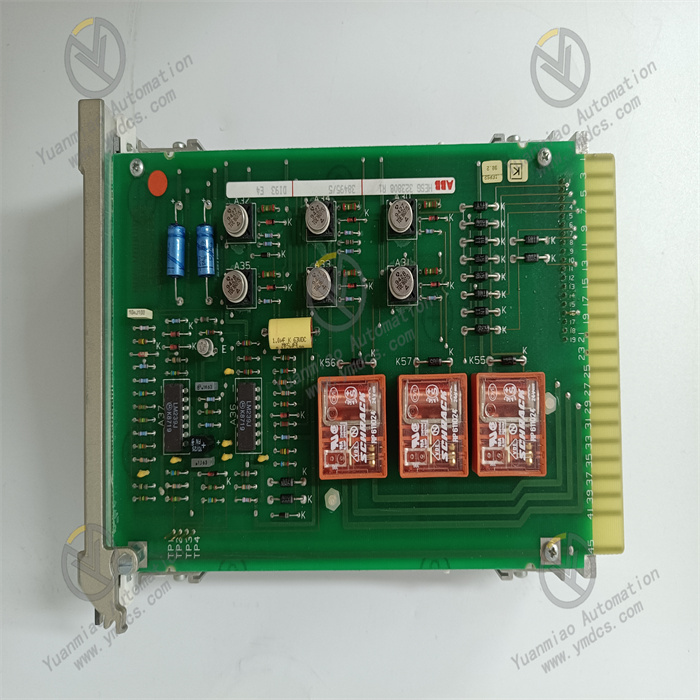

- Anti-interference and Durability: Uses industrial-grade components and reinforced PCBs, capable of withstanding 10-500Hz mechanical vibration (amplitude ≤0.5mm) and 500V surge impact. It complies with the IEC 61000-4 electromagnetic compatibility standard and can operate stably in strong interference environments with dense frequency converters and high-voltage motors.

- Built-in Triple Core Protection: Overcurrent protection (instantly cuts off output when the output current exceeds 40A), overvoltage protection (triggers protection when the output voltage fluctuation exceeds ±15%), and short-circuit protection (responds within 10μs when a load short circuit is detected), fundamentally avoiding the risk of drive and motor burnout.

- Over-temperature Protection Function: Automatically reduces output when the internal temperature exceeds 95°C, and resumes normal operation when the temperature drops below 80°C, balancing equipment protection and production continuity.

- Drive Compatibility: Natively compatible with various series of GE industrial drives, and also supports signal connection with mainstream third-party drives (such as Siemens S120 series and Schneider Lexium series).

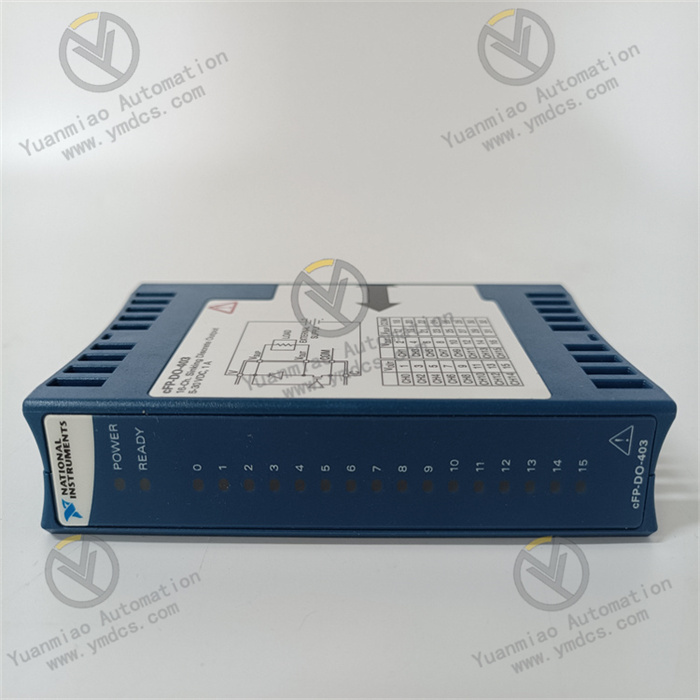

- Communication Interfaces: Reserved RS485 and CAN bus interfaces, supporting the Modbus RTU protocol. It can be connected to DCS or PLC systems to realize remote status monitoring and parameter configuration.

An ultra-high conversion efficiency of 95% means that only 500W is lost for every 10kW of input power. Calculated based on industrial equipment operating 24 hours a day and 300 days a year, a single device can save approximately 360kWh of electrical energy annually, significantly reducing the enterprise's electricity costs. At the same time, its output voltage ripple coefficient is ≤0.5%, far lower than the industry average of 1%, providing "fluctuation-free" electrical energy for the drive, reducing motor operating noise and heat generation, and extending the service life of the equipment.

Different from traditional power modules that only provide power supply, the RV33-1 deeply integrates power supply and control functions. It can realize motor speed, position, and torque adjustment without additional control modules. For example, in SMT placement equipment, this power board can directly cooperate with the drive to achieve precise positioning (±0.05mm) of the placement head and speed adjustment (switching 500-2000rpm according to component size), simplifying the system architecture and reducing integration costs.

The combination of IP65 protection level and wide-temperature design (-40°C to 85°C) makes it a multi-scenario universal product: in the oil and gas industry, it can be directly installed in open-air control cabinets in oil and gas fields to resist sand, dust, and day-night temperature differences; in medical imaging equipment, it can operate stably for a long time in closed equipment cabins to ensure the continuous power supply of CT and MRI equipment. The use of industrial-grade components enables its MTBF (Mean Time Between Failures) to reach more than 100,000 hours. Calculated based on 8 hours of operation per day, the theoretical trouble-free operation can reach 34 years.

The triple protection mechanism forms an all-round safety barrier, which can quickly respond to sudden faults such as short circuits in welding equipment and motor stalling, reducing equipment maintenance costs. The modular design allows replacement by only removing 2 fixing screws and plugging/unplugging 3 terminals, and the replacement time of a single module can be controlled within 5 minutes, greatly reducing the downtime of the production line. In addition, the on-board status indicator lights can intuitively display the power on/off, overload, over-temperature, and other statuses, facilitating quick on-site troubleshooting of basic faults.

In the automotive parts welding production line, the RV33-1 serves as the core power supply for the welding robot drive and undertakes dual roles:

- Stable Power Supply: Provides a stable 33A current for the welding robot servo drive, ensuring the continuous stability of the welding arc and avoiding weld defects caused by current fluctuations.

- Precise Control: Through the integrated torque control function, it automatically adjusts the welding pressure according to the thickness of different steel plates (torque output adjustable from 0 to 50N·m), and cooperates with position control to achieve ±0.1mm positioning accuracy of the welding point.

- Fault Protection: When a short circuit occurs in the welding torch, the short-circuit protection function instantly cuts off the power supply to avoid drive burnout, and at the same time uploads the fault signal to the workshop MES system through the RS485 interface.

In the drive system of isolating switches for high-voltage power transmission and transformation lines, this power board realizes the following functions:

- Adaptation to Extreme Environments: The -40°C low-temperature resistance meets the winter operation needs of outdoor substations in northern regions, and the IP65 protection level resists rain, snow, and sand.

- Reliable Drive: Provides a stable power supply for the frequency converter of the isolating switch drive motor, and the 33A output current supports the rapid start-stop of the motor (completing the opening and closing action within 0.5 seconds).

- Safety Interlocking: Links with the power transmission and transformation DCS system. When an overcurrent fault is detected, it automatically cuts off the drive power supply and locks the isolating switch operation to prevent power grid accidents caused by misoperation.

In the rotation drive system of hospital CT scanners, the core value of the RV33-1 is reflected in:

- Low Ripple Power Supply: The output ripple of ≤0.5% ensures the uniform rotation of the CT rotating frame (speed 300rpm, fluctuation ≤1rpm), improving image clarity.

- Quiet Operation: The high-efficiency conversion design reduces the power supply operating noise (≤40dB), and its compact structure allows integration inside the equipment, avoiding interference with the diagnosis and treatment environment.

- Continuous Operation Guarantee: The MTBF of more than 100,000 hours ensures the year-round trouble-free operation of the equipment, meeting the 24-hour emergency needs of the hospital.

In the integrated control cabinet of urban traffic signal lights and monitoring systems, the application advantages of this power board are significant:

- Wide Temperature and Protection: The 85°C high-temperature resistance adapts to the exposure environment of outdoor control cabinets in summer, and the IP65 protection isolates rainwater and dust.

- Energy Saving and Stability: The 95% conversion efficiency reduces the energy consumption of transportation equipment, and the overvoltage protection function resists damage to signal lights and cameras caused by power grid voltage fluctuations.

- Remote Monitoring: Connects to the traffic control platform through the CAN bus, uploads the power supply operating status in real time, and realizes early fault warning and remote diagnosis.

- When using DIN rail mounting, ensure that the rail load capacity is ≥5kg, and reserve a gap of ≥10mm between modules to avoid mutual influence on heat dissipation of adjacent equipment; for embedded mounting, the panel opening size must match the module's external dimensions (tolerance ≤±0.5mm) to prevent vibration caused by loose installation.

- The installation location should be far away from strong heat sources (such as heaters and high-power resistors) and strong electromagnetic interference sources (such as frequency converters and high-voltage cables), with a distance of ≥30cm.

- Use 4mm² copper core cables on the input side. When connecting to three-phase 380V/480V power supply, strictly distinguish between phase wires (L1/L2/L3) and neutral wire (N). The grounding terminal (PE) must use a dedicated grounding wire (cross-section ≥2.5mm²) with a grounding resistance of ≤4Ω.

- For the output side wiring, select cables according to the rated current of the drive (it is recommended to use ≥6mm² copper core cables). The terminal tightening torque must be ≥2.5N·m to prevent heat generation due to poor contact; use shielded twisted-pair cables for communication cables, with the shield layer grounded at one end, and the distance from power cables should be ≥15cm.

![]()