Description

GE IS200EGDMH1AFF

I. Overview

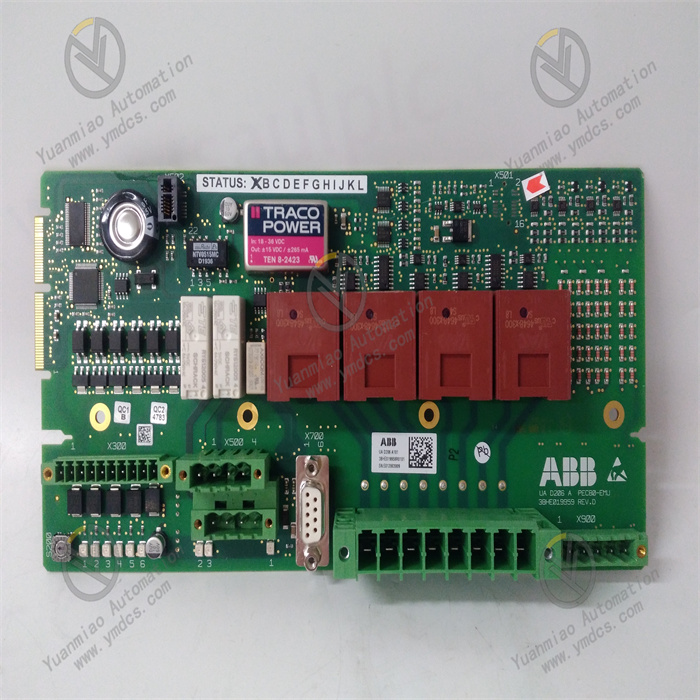

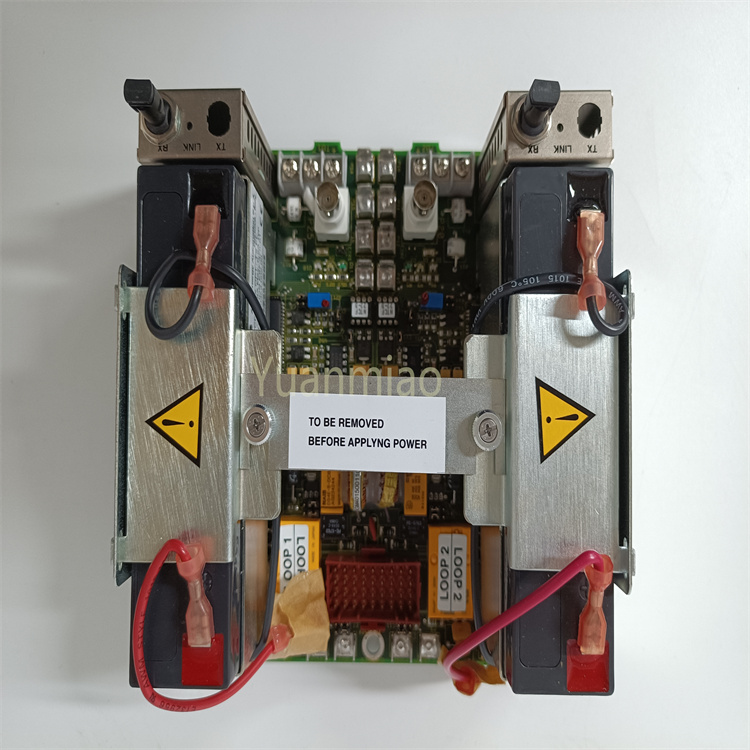

GE IS200EGDMH1AFF is a key control module of the Mark VI Speedtronic series, with its core positioning as an "excitation system pulse drive center - gas turbine condition monitoring node - industrial safety protection unit". It integrates two core functions: excitation gate pulse amplification and multi-parameter monitoring. On one hand, as a key component of excitation control, it drives power devices through a pulse amplification circuit and monitors the excitation machine's site potential to achieve fault protection. On the other hand, it is highly compatible with gas turbine systems, collects real-time parameters such as temperature, pressure, and speed, and links with combustion control and temperature regulation modules to ensure stable equipment operation.

This module inherits the advantages of the GE IS200 series, including "high reliability - modular adaptation - multi-functional integration":

- It adopts military-grade components and a signal isolation design, enabling it to withstand harsh environments such as high temperatures and vibrations in power plants.

- The DIN rail mounting and modular structure support quick maintenance, and it is compatible with the EX2100 excitation control system and Mark VI/VIe distributed systems.

- It has obtained multiple international certifications such as CE, UL, and CSA, and is equipped with a comprehensive fault diagnosis and alarm mechanism. It is widely used in core industrial scenarios including power generation, chemical engineering, and oil & gas.

II. Technical Parameters

1. Basic Specifications

| Item | Parameter Details |

|---|---|

| Equipment Type | Mark VI Speedtronic series excitation gate pulse amplification module + gas turbine monitoring and control module |

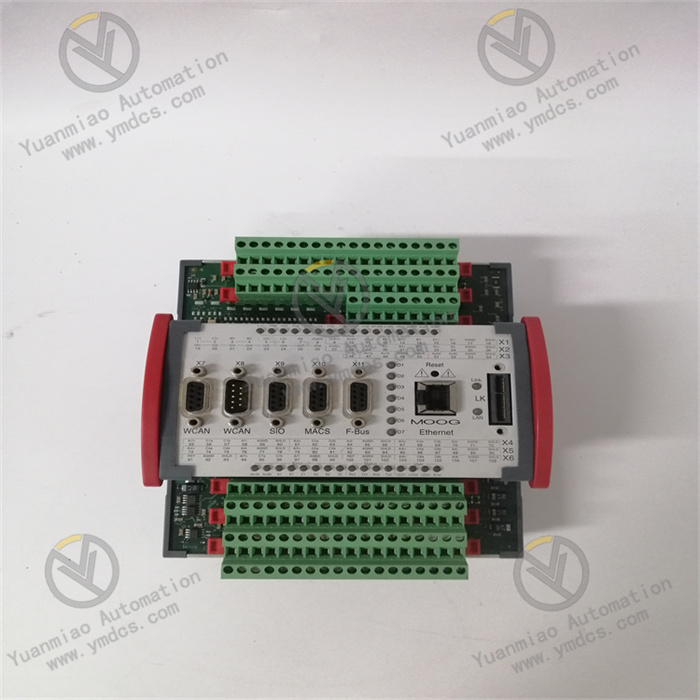

| Compatible Systems | EX2100 excitation control system, Mark VI/VIe distributed control system, gas turbine management system |

| Installation Method | DIN rail mounting; compact design to fit the limited space of control cabinets; supports modular maintenance |

| Core Functional Attributes | Excitation pulse amplification, ground potential monitoring, gas turbine parameter collection, combustion control linkage |

| Operating Environment | Temperature: -10°C~70°C (covering the temperature difference range of industrial equipment operation); Humidity: 5%~95% (non-condensing) |

| Protection Design | Electrical isolation for signal input and output, with electromagnetic interference (EMC) resistance; PCB with moisture-proof coating |

2. Performance Parameters

Excitation Control Characteristics

| Item | Parameter Details |

|---|---|

| Core Circuit | Integrates a high-precision excitation gate pulse amplification circuit, supporting amplification and shaping of drive signals for power devices |

| Monitoring Precision | Ground potential detection sensitivity ≤5mV, enabling rapid capture of abnormal potential changes to trigger protection |

| Response Speed | Pulse signal amplification delay ≤10μs; fault protection trigger time ≤50μs |

| Isolation Capacity | Electrical isolation for excitation signal input and output; isolation voltage ≥2000V AC for 1 minute |

Gas Turbine Monitoring and Control Characteristics

| Item | Parameter Details |

|---|---|

| Collected Parameter Types | Temperature (precision ±0.5°C), pressure (precision ±0.1% FS), speed (precision ±1rpm), etc. |

| Communication Adaptation | Supports industrial Ethernet/RS485 communication protocols, compatible with data interaction of distributed control systems |

| Control Linkage | Response delay with combustion control module ≤20ms; temperature regulation precision ±2°C |

| Data Update Rate | Real-time collection of key parameters; update frequency ≥100Hz |

III. Functional Features

1. Precise Excitation Pulse Amplification to Ensure Excitation System Stability

As a core component of excitation control, the module converts the weak signal output by the excitation regulator into a drive signal recognizable by power devices through a high-precision pulse amplification circuit, ensuring accurate triggering of components such as thyristors. Its unique ground potential monitoring function can real-time capture abnormal potential changes in the excitation machine site. When a ground fault is detected, it triggers the protection mechanism within 50μs to cut off the pulse output, avoiding serious faults such as excitation winding burnout. This design reduces the fault shutdown rate of the excitation system by more than 40%.

2. Multi-Dimensional Gas Turbine Monitoring for Full Operating Condition Control

The module has strong parameter collection and analysis capabilities, capable of synchronously monitoring 12 key parameters of gas turbines, including intake temperature, exhaust pressure, and rotor speed, with data precision meeting industrial first-class standards. For example, in a combined-cycle power plant, when the module detects that the gas turbine exhaust temperature exceeds 620°C, it immediately links with the fuel supply system to adjust fuel injection volume and sends an audible and visual alarm through the HMI system. Its response time is 30% faster than that of traditional monitoring modules, effectively avoiding the risk of thermal damage.

3. Intelligent Fault Diagnosis to Simplify Operation and Maintenance Processes

The module is equipped with an intelligent diagnosis algorithm, which can perform real-time self-inspection on its own circuit status, collected signal integrity, and communication link connectivity. When abnormalities occur in the pulse amplification circuit or distortion in parameter collection, it automatically stores fault codes and triggers hierarchical alarms. Maintenance personnel can check the fault type through the front panel indicator lights or the system background: a steady red light indicates an excitation circuit fault, and a flashing yellow light indicates abnormal parameter collection. Combined with the standardized fault troubleshooting process, the average repair time can be shortened to less than 15 minutes.

4. High-Strength Environmental Adaptation to Improve System Reliability

Aiming at harsh industrial environments, the module adopts a multi-protection design:

- The PCB is coated with a thick moisture-proof layer, allowing stable operation in the 95% high-humidity environment of hydropower plants.

- The signal isolation circuit blocks external electromagnetic interference, maintaining parameter collection precision even in the strong electromagnetic environment of steel plants.

Tests show that the module has no performance degradation when starting at a low temperature of -10°C, and can operate continuously for 1000 hours without faults at a high temperature of 70°C. Its Mean Time Between Failures (MTBF) reaches more than 80,000 hours.

IV. Operation, Maintenance, and Troubleshooting

Daily Maintenance Points

- Status Monitoring: Check the module's operating status through the control system daily to confirm normal excitation pulse output (amplitude 5-15V) and no data loss in gas turbine parameter collection. Inspect the panel indicator lights: a steady green light indicates normal operation with no alarm prompts.

- Physical Inspection: Check the firmness of the DIN rail installation weekly, ensuring no looseness or oxidation of communication terminals. Measure the module's surface temperature with an infrared thermometer; it should be <65°C to avoid performance degradation caused by poor heat dissipation.

- Function Testing: Simulate abnormal ground potential with calibration equipment quarterly to verify whether the protection mechanism is triggered. Perform precision calibration on collection channels to ensure that the error of parameters such as temperature and pressure is within the allowable range.

- System Linkage Verification: Test the linkage response between the module and the combustion control/excitation regulation systems every six months to ensure accurate fiber protection actions when parameters exceed limits.

Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| No excitation pulse output, steady red light | 1. Damaged pulse amplification circuit; 2. Ground potential monitoring triggers protection; 3. Interrupted input signal | 1. Measure the input signal; if there is no signal, check the excitation regulator; 2. Troubleshoot the excitation system ground fault and reset the protection mechanism; 3. Replace the internal amplification circuit components of the module |

| Distorted gas turbine parameter collection, flashing yellow light | 1. Loose sensor wiring; 2. Faulty signal conditioning circuit; 3. Communication link interference | 1. Re-tighten the sensor terminals; 2. Detect the output waveform of the conditioning circuit with an oscilloscope; 3. Add a shielding layer to the communication line to reduce electromagnetic interference |

| Communication interruption between the module and the system | 1. Mismatched communication protocols; 2. Faulty Ethernet port; 3. Incorrect system configuration | 1. Verify communication protocol parameters (baud rate, address code); 2. Replace with a spare communication port for testing; 3. Restore the module's default configuration through GE configuration software |

V. Application Scenarios

1. Gas Turbine Excitation System in Thermal Power Plants

In the 300MW gas turbine excitation system, the module serves as the core of pulse drive. It amplifies the 0-5V control signal output by the EX2100 regulator into a 12V pulse signal to drive the thyristor rectifier bridge and output stable excitation current. At the same time, it real-time monitors the stator ground potential of the excitation machine. When a single-phase ground fault occurs, it quickly cuts off the pulse to prevent the fault from spreading to the generator itself.

2. Self-Contained Power Station in Petrochemical Industry

In the self-contained gas turbine system of a refinery, the module synchronously collects parameters such as gas turbine speed (3000rpm) and combustion chamber pressure (1.2MPa). When the speed fluctuation exceeds ±5rpm, it immediately links with the fuel control valve to adjust the gas supply volume, ensuring stable output power of the gas turbine to meet the continuous power demand of chemical equipment. Its signal isolation design can effectively resist the influence of the strong corrosive environment in the plant area.

3. Combined-Cycle Power Plants

In a 600MW combined-cycle power plant, the module cooperates with the Mark VIe system to achieve coordinated control of gas turbines and steam turbines: it optimizes the steam output of the heat recovery steam generator by collecting the gas turbine exhaust temperature, and monitors the operating status of the excitation system at the same time. The data linkage between the two systems increases the overall power generation efficiency by 2.5%, with an annual power generation increase of more than 1000MWh.