Description

GE IS200SDIIH1ADB

I. Product Overview

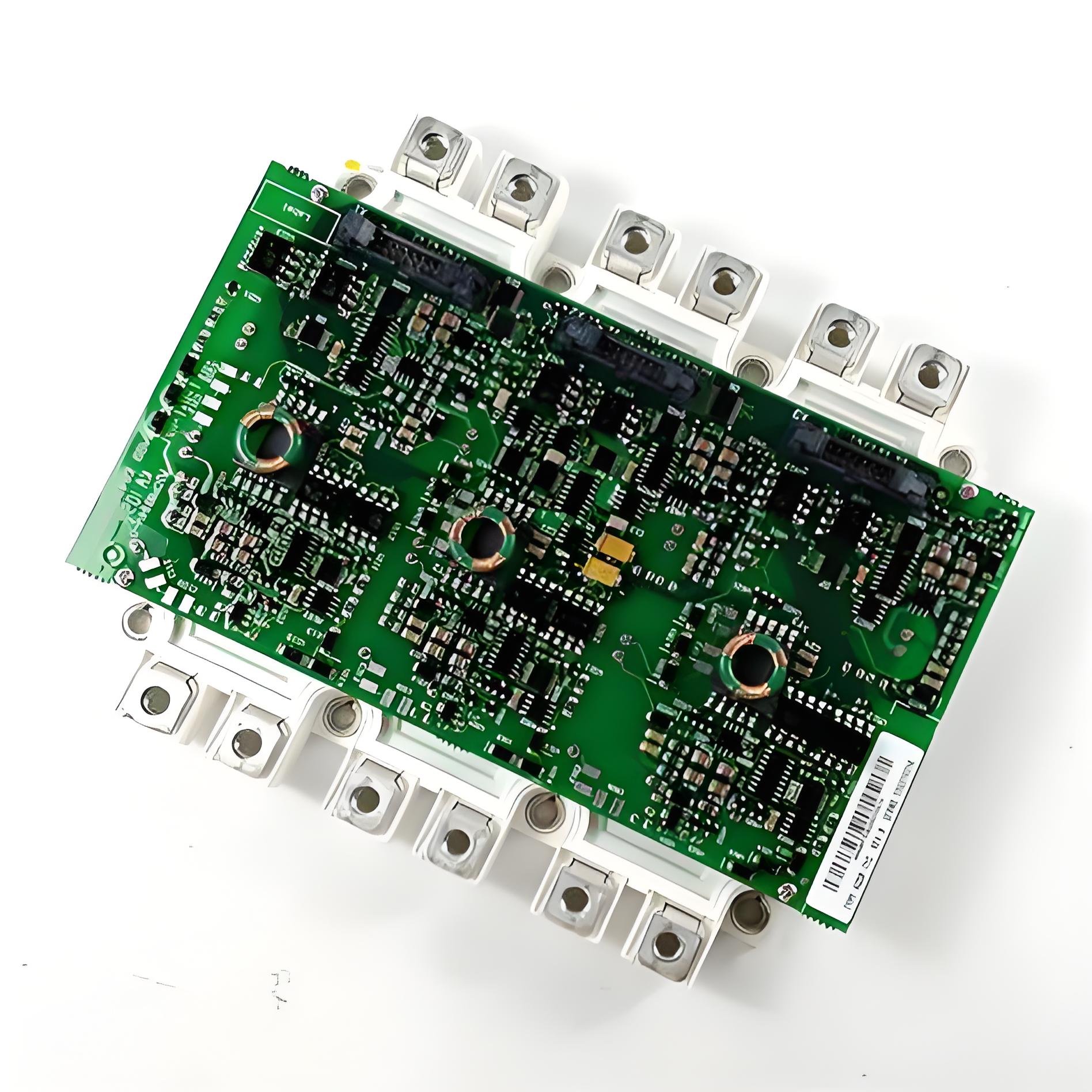

IS200SDIIH1ADB adopts a compact modular structure, with its overall dimensions carefully designed, and the length, width, and height are [specific dimension values] respectively. This design enables it to easily fit into the cabinets of GE's Mark VIe and other control systems, achieving seamless integration with other modules. It allows for efficient layout in limited space, greatly improving the integration level and space utilization of industrial control systems. Whether in the complex cabinet combinations of large industrial control centers or in small control equipment with limited space, it can be flexibly installed, facilitating the overall planning of the system.

The shell of the module is made of high-strength, corrosion-resistant industrial-grade materials, with excellent protective performance. It can effectively resist the impact of common adverse factors in industrial sites such as dust, vibration, and electromagnetic interference, providing reliable physical protection for the internal precision electronic components. Even in harsh environments such as dusty cement plants and metallurgical workshops with large vibrations, it can maintain a stable working state, ensuring the long-term and reliable operation of the module.

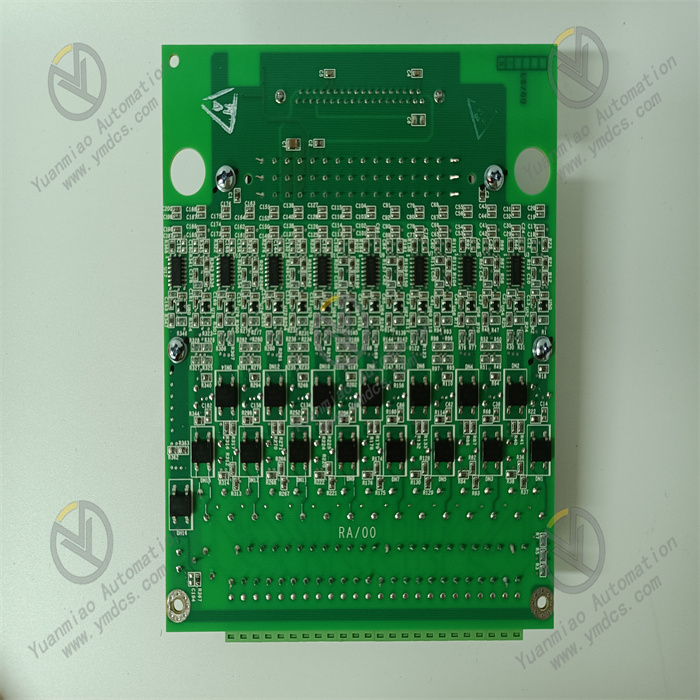

IS200SDIIH1ADB integrates high-precision signal detection circuits and advanced logic processing chips. The selected electronic components have undergone strict quality screening and reliability testing, featuring low power consumption, high stability, and long service life. The optimized circuit layout not only reduces interference during signal transmission and improves the accuracy of data collection but also enhances the module's anti-electromagnetic interference capability. This enables it to accurately collect and process digital signals in complex industrial electromagnetic environments, providing a reliable data basis for the precise decision-making of industrial control systems.

II. Performance Parameters

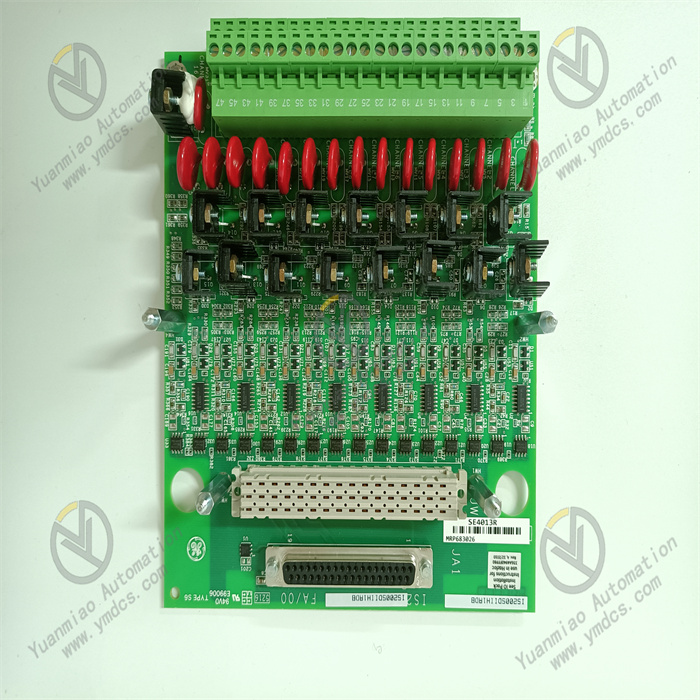

Number of input channels: Equipped with [specific number of channels] independent digital input channels, which can collect multiple digital signals simultaneously, meeting the needs of multi-equipment status monitoring in industrial sites. For example, in an automated production line, it can monitor the start-stop status and fault alarm signals of multiple devices at the same time.

Type of input signals: Supports two types of digital input signals: dry contacts and wet contacts. Dry contact input does not require an external power supply and is suitable for connecting various mechanical contact switches, such as limit switches and buttons; wet contact input requires an external power supply with a specific voltage and can be connected to devices that actively output digital signals, such as photoelectric sensors and proximity switches, with strong compatibility and adaptability to various industrial scenarios.

Input voltage range: For wet contact input, the supported voltage range is [specific voltage range], such as 24V DC, 120V AC and other common industrial voltage specifications, which can perfectly match different types of sensors and equipment, improving the versatility of the module.

Response time: The response time of the input signal is extremely short, only [specific response time] ms, which can quickly capture the state changes of the input signal, ensuring real-time monitoring of the status of industrial on-site equipment. For example, when a device fails, the module can quickly detect the fault signal and upload it to the control system for timely countermeasures.

(2) Signal Processing and Transmission

Signal filtering: Built-in digital filtering function can effectively remove high-frequency noise and interference pulses in the input signal, improving the stability and reliability of the signal. Users can adjust the filtering time constant through parameter configuration according to the noise situation of the actual application scenario to ensure that the collected signal truly reflects the actual state of the equipment.

Signal filtering: Built-in digital filtering function can effectively remove high-frequency noise and interference pulses in the input signal, improving the stability and reliability of the signal. Users can adjust the filtering time constant through parameter configuration according to the noise situation of the actual application scenario to ensure that the collected signal truly reflects the actual state of the equipment.

Data transmission rate: It communicates with the controller through the high-speed data bus inside the system, with a high data transmission rate of up to [specific transmission rate], which can transmit the collected digital signals to the control system in real-time, ensuring that the control system can obtain equipment status information in a timely manner and make quick responses.

(3) Power Supply Characteristics

It is powered by [specific voltage value] DC power supply, which is compatible with the DC power supply systems commonly used in industrial sites and is easy to connect. The power input port is equipped with overvoltage and overcurrent protection functions. When there is an abnormal fluctuation in the power supply, such as excessive voltage or current, it can quickly cut off the power input to protect the internal circuit of the module from damage, improving the safety and anti-interference ability of the module. In normal working conditions, the power consumption of the module is low, only [specific power consumption value] W, which meets the requirements of energy conservation and environmental protection, and at the same time reduces the heat generation during the module's operation, extending its service life.

It is powered by [specific voltage value] DC power supply, which is compatible with the DC power supply systems commonly used in industrial sites and is easy to connect. The power input port is equipped with overvoltage and overcurrent protection functions. When there is an abnormal fluctuation in the power supply, such as excessive voltage or current, it can quickly cut off the power input to protect the internal circuit of the module from damage, improving the safety and anti-interference ability of the module. In normal working conditions, the power consumption of the module is low, only [specific power consumption value] W, which meets the requirements of energy conservation and environmental protection, and at the same time reduces the heat generation during the module's operation, extending its service life.

(4) Environmental Adaptability

Operating temperature range: It can work stably in the ambient temperature range of [specific temperature range], and can adapt to temperature changes in industrial sites. Whether in high-temperature steelmaking workshops or low-temperature outdoor control equipment, it can maintain normal working performance, ensuring the continuity and accuracy of data collection.

Operating temperature range: It can work stably in the ambient temperature range of [specific temperature range], and can adapt to temperature changes in industrial sites. Whether in high-temperature steelmaking workshops or low-temperature outdoor control equipment, it can maintain normal working performance, ensuring the continuity and accuracy of data collection.

Vibration and shock resistance: It has good vibration and shock resistance, and can withstand the impact of common vibrations and shocks in industrial sites. After strict vibration tests and shock tests, the module can still work normally under the conditions of vibration frequency [specific frequency range], acceleration [specific acceleration value], and impact acceleration [specific impact acceleration value], ensuring reliability during transportation, installation, and operation.

Electromagnetic compatibility: It complies with international electromagnetic compatibility standards and has excellent anti-electromagnetic interference ability and low electromagnetic radiation characteristics. In industrial sites with a large number of high-voltage equipment and high-frequency interference sources, the module will not be affected by external electromagnetic interference, and at the same time, it will not cause electromagnetic interference to surrounding equipment, ensuring the stable operation of the entire industrial control system.

(5) Diagnostic and Protection Functions

Self-diagnostic function: It has a perfect self-diagnostic function, which can monitor the power supply status, channel status, communication status, etc. of the module in real-time. When the module itself fails, such as power failure, channel short circuit, communication interruption, etc., it will automatically generate a fault code, upload the fault information to the control system through the communication interface, and light up the corresponding fault indicator at the same time, facilitating maintenance personnel to quickly locate the cause of the fault and improve the efficiency of fault troubleshooting.

Self-diagnostic function: It has a perfect self-diagnostic function, which can monitor the power supply status, channel status, communication status, etc. of the module in real-time. When the module itself fails, such as power failure, channel short circuit, communication interruption, etc., it will automatically generate a fault code, upload the fault information to the control system through the communication interface, and light up the corresponding fault indicator at the same time, facilitating maintenance personnel to quickly locate the cause of the fault and improve the efficiency of fault troubleshooting.

Channel protection: Each input channel is equipped with overvoltage and overcurrent protection circuits. When the input signal has abnormal conditions such as overvoltage and overcurrent, the protection circuit will act quickly to cut off the connection between the channel and the internal circuit, avoiding damage to the module by abnormal signals, and at the same time, it will not affect the normal operation of other channels, improving the safety and reliability of the module.

(6) Configuration and Compatibility

Configuration method: It supports parameter configuration and channel mapping through GE's dedicated programming software (such as Proficy Machine Edition). The software interface is intuitive and user-friendly, and easy to operate. Engineers can set the type of input channels, filtering parameters, alarm thresholds, etc. according to actual needs to realize personalized configuration of the module and meet the application needs of different industrial scenarios.

Configuration method: It supports parameter configuration and channel mapping through GE's dedicated programming software (such as Proficy Machine Edition). The software interface is intuitive and user-friendly, and easy to operate. Engineers can set the type of input channels, filtering parameters, alarm thresholds, etc. according to actual needs to realize personalized configuration of the module and meet the application needs of different industrial scenarios.

System compatibility: It is perfectly compatible with GE's Mark VIe and other series of control systems, and can be directly connected to the system bus without additional interface conversion equipment, simplifying the system integration process and reducing the complexity and cost of the system. At the same time, it also supports docking with control systems of other brands through standard communication protocols, with certain openness and compatibility.

III. Application Scenarios

In the control of generator sets in the electric power industry, IS200SDIIH1ADB can be used to collect various status signals of generator sets, such as the opening and closing status of circuit breakers, the position signals of disconnectors, the start-stop status of motors, and the action signals of temperature switches. These signals are transmitted to the generator set control system in real-time, and the control system judges the operating status of the equipment according to these signals, realizes the start-stop control of the generator set, triggers protection logic and other functions, and ensures the safe and stable operation of the generator set. For example, when a signal indicating that the generator temperature is too high is detected, the control system can issue a shutdown command in time to avoid equipment damage.

(2) Petroleum and Chemical Industry

In the petroleum and chemical production process, there are a large number of pumps, valves, compressors and other equipment. IS200SDIIH1ADB can be used to monitor the operating status of these equipment. Such as monitoring the running/stopping status of pumps, the opening/closing status of valves, and the fault alarm signals of equipment. By uploading these signals to the DCS (Distributed Control System), operators can grasp the operation of the equipment in real-time. When the equipment is abnormal, the DCS system can issue an alarm in time and automatically take corresponding control measures, such as closing relevant valves and stopping the operation of upstream and downstream equipment, to prevent the expansion of accidents and ensure production safety.

In the petroleum and chemical production process, there are a large number of pumps, valves, compressors and other equipment. IS200SDIIH1ADB can be used to monitor the operating status of these equipment. Such as monitoring the running/stopping status of pumps, the opening/closing status of valves, and the fault alarm signals of equipment. By uploading these signals to the DCS (Distributed Control System), operators can grasp the operation of the equipment in real-time. When the equipment is abnormal, the DCS system can issue an alarm in time and automatically take corresponding control measures, such as closing relevant valves and stopping the operation of upstream and downstream equipment, to prevent the expansion of accidents and ensure production safety.

(3) Manufacturing Automated Production Lines

In manufacturing automated production lines, IS200SDIIH1ADB can be widely used in equipment status monitoring and production process control. For example, in an automobile manufacturing production line, it can collect the working status signals of welding robots, the running status signals of conveyor belts, and the detection signals of workpiece positioning sensors. The control system coordinates the working rhythm of various equipment according to these signals to ensure the smooth progress of the production process. When a device fails, the module can quickly detect the fault signal, and the production line control system can pause the relevant processes in time to avoid the production of unqualified products and improve production efficiency and product quality.

In manufacturing automated production lines, IS200SDIIH1ADB can be widely used in equipment status monitoring and production process control. For example, in an automobile manufacturing production line, it can collect the working status signals of welding robots, the running status signals of conveyor belts, and the detection signals of workpiece positioning sensors. The control system coordinates the working rhythm of various equipment according to these signals to ensure the smooth progress of the production process. When a device fails, the module can quickly detect the fault signal, and the production line control system can pause the relevant processes in time to avoid the production of unqualified products and improve production efficiency and product quality.

(4) Metallurgical Industry

In the steel production process of the metallurgical industry, the environment with high temperature, high vibration, and much dust has extremely high requirements on the reliability of equipment. IS200SDIIH1ADB can be used to monitor the status of various auxiliary equipment of blast furnaces, converters, rolling mills and other equipment, such as the operation status of cooling water pumps, the start-stop status of fans, and the switch position of valves. By collecting these signals in real-time, the control system can timely understand the operation status of the equipment, ensure the normal operation of auxiliary equipment, and provide a guarantee for the stable progress of steel production. For example, when a signal indicating that the cooling water pump has stopped running is detected, the control system can immediately issue an alarm and take emergency measures to prevent high-temperature equipment from being damaged due to insufficient cooling.

In the steel production process of the metallurgical industry, the environment with high temperature, high vibration, and much dust has extremely high requirements on the reliability of equipment. IS200SDIIH1ADB can be used to monitor the status of various auxiliary equipment of blast furnaces, converters, rolling mills and other equipment, such as the operation status of cooling water pumps, the start-stop status of fans, and the switch position of valves. By collecting these signals in real-time, the control system can timely understand the operation status of the equipment, ensure the normal operation of auxiliary equipment, and provide a guarantee for the stable progress of steel production. For example, when a signal indicating that the cooling water pump has stopped running is detected, the control system can immediately issue an alarm and take emergency measures to prevent high-temperature equipment from being damaged due to insufficient cooling.