Description

GE IC752SPL013-BA

I. Product Overview

II. Technical Parameters

Signal Processing Capability: It performs excellently in signal processing and can support the processing of multiple complex signal types. Whether it is digital signals or analog signals, it can flexibly adapt and efficiently process them according to the characteristics of the connected devices. For example, in practical applications of turbine control systems, it can simultaneously receive analog signals output from various sensors such as temperature, pressure, and flow, as well as digital signals from control units. Through built-in advanced algorithms and processing chips, it accurately analyzes, converts, and integrates these signals, providing a precise data foundation for system decision-making and control, thereby realizing effective management and optimization of complex industrial control systems.

Electrical Characteristics: In terms of working voltage, its design has a relatively wide adaptation range, usually capable of stable operation under 18 - 36 V DC voltage. This wide voltage adaptation range enables the device to maintain a stable working state in the face of complex and variable power supply environments in industrial sites, with strong tolerance to common power fluctuations, effectively reducing the risk of equipment failure caused by power supply issues. In terms of power consumption, the product is meticulously designed, and its power consumption is at a reasonable level under normal working conditions. A 12-watt power supply is sufficient to meet its operational needs, without imposing excessive burden on the system power supply, ensuring the overall energy utilization efficiency and stability of the system. In addition, in terms of electrical compatibility, the device is well-designed and can coexist harmoniously with other electrical equipment in the system, effectively avoiding electrical interference problems and ensuring the stable operation of the entire system.

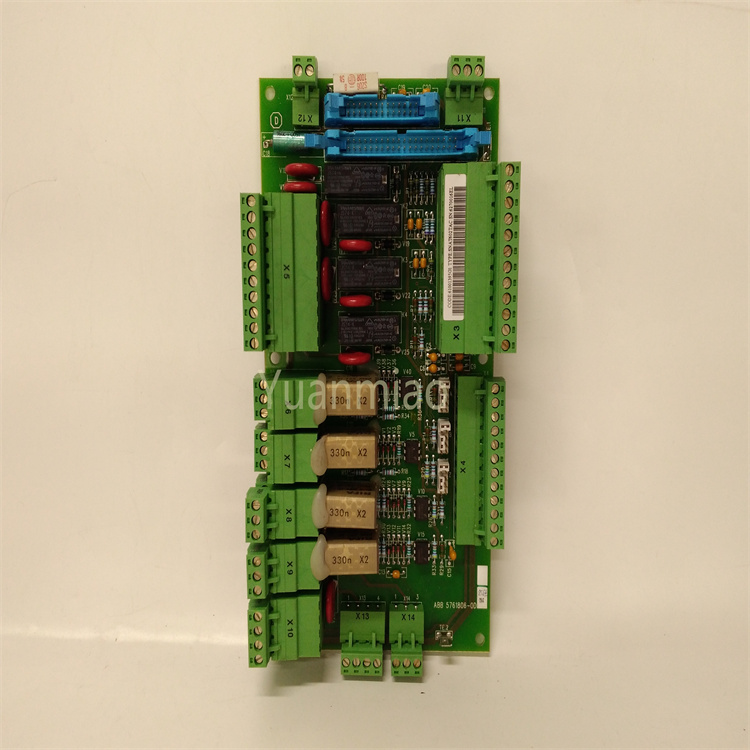

Hardware Composition: The hardware layout of IC752SPL013 - BA is extremely exquisite, with various key components reasonably distributed on both the upper and lower surfaces of the circuit board. On the top surface, there is a high-precision jack connector for achieving reliable connection with external devices. The board is also equipped with two high-performance transformers of specific models, such as Halo TG 110 - EO 50 N 5 transformers, which play a key role in power conversion and distribution. At the same time, it is equipped with six meticulously calibrated inductors, numerous high-performance transistors, and a large number of high-precision resistors, capacitors, and diodes. 尤为重要的是,more than 20 advanced integrated circuits are distributed among them, among which the Field-Programmable Gate Array (FPGA) located at position U1 is the core of the core. With its powerful programmable features, FPGA can flexibly implement various complex signal processing and control algorithms, providing a solid guarantee for the high-performance operation of the device. On the bottom surface, additional connectors, resistors, transistors, capacitors, and other components are also arranged. These components work together closely to complete a series of complex functions such as signal processing, communication, and human-machine interaction, ensuring that the device can operate stably and efficiently.

III. Functional Features

Convenient Human-Machine Interaction: As an operator interface panel, IC752SPL013 - BA has significant advantages in human-machine interaction. It is equipped with an intuitive and easy-to-understand operation interface, allowing operators to get started easily and perform various operations quickly. Through the clear display screen and reasonably arranged buttons, operators can conveniently input control commands, query system operation parameters, obtain equipment status information, etc. This convenient human-machine interaction design greatly improves the work efficiency of operators, reduces the possibility of operational errors, and makes the control and management in the industrial production process more precise and efficient.

Powerful Communication Function: With advanced communication interface technology, this device realizes high-speed and stable communication between different components in the system. It can transmit a large amount of data quickly and accurately, ensuring that key parameters during turbine operation, such as rotational speed, temperature, and pressure, are timely fed back to the control system, and at the same time, control commands are accurately transmitted to the corresponding actuators. In complex industrial production scenarios, it can seamlessly communicate with multiple devices and system modules, realizing data sharing and collaborative work, providing strong support for real-time monitoring and precise control of industrial production processes, and meeting the urgent needs of modern industrial production for efficient and precise control.

Signal Conversion and Processing: It has strong signal conversion and processing capabilities, which can convert the original signals collected by sensors into a format suitable for system processing and transmission. In this process, it performs necessary processing and conditioning on the signals, using advanced filtering algorithms and signal enhancement technologies to effectively remove noise interference and greatly improve signal quality and accuracy. The high-quality signals after processing provide reliable data support for the control system, strongly ensuring the precision of industrial equipment control, helping to improve the product quality and production efficiency of industrial production, and reducing production costs.

Isolation Protection: It adopts advanced electrical isolation technology to effectively isolate electrical interference between different circuits, significantly improving the anti-interference ability and reliability of the system. In industrial sites, various electrical equipment will generate complex and variable electromagnetic interference during operation, and the isolation protection function of IC752SPL013 - BA can ensure that it still works normally in such harsh environments, avoiding the adverse impact of interference on signal transmission and system control, maintaining the stable operation of the system, and providing reliable guarantee for the continuity and stability of industrial production.

Support for Customized Functions: It can usually be custom-designed according to the specific needs of customers, with high flexibility. Different industrial application scenarios have different requirements for control systems. Through customized functions, the device can better meet the personalized needs of customers and create targeted solutions for them. Whether in terms of function configuration, interface customization, or personalized design of the operation interface, it can meet the special requirements of customers, improve the applicability and performance of the system in specific scenarios, and create greater value for customers.

IV. Common Problems and Maintenance

Repair and Refurbishment: Once the device fails, a professional maintenance team can use professional tools and equipment to conduct rapid testing, accurate diagnosis, and efficient repair in a strictly controlled environment. The spare parts required for maintenance are usually in sufficient stock, and the replaced parts are all of industrial grade, with performance meeting or exceeding the requirements of the Original Equipment Manufacturer (OEM). After the repair is completed, a comprehensive and strict functional verification test will be conducted on the device to ensure that all functions of the device return to normal, and corresponding quality assurance services will be provided to customers, so that customers have no worries. For devices that have been used for a long time but are not completely damaged, refurbishment can effectively extend their service life. The refurbishment process covers multiple key steps, including replacing aging and easily failing components, making technical improvement and upgrade (TIL) modifications according to actual needs, performing fine reflow soldering on solder joints to eliminate hidden dangers of cold solder joints, thoroughly cleaning the circuit board in accordance with strict industrial standards, and applying high-quality protective coatings, etc., so that the device performance is effectively restored and improved.

Functional Verification Testing: To ensure the reliability and stability of GE IC752SPL013 - BA, comprehensive and detailed functional verification tests are usually carried out in the actual OEM system setup. During the test, all input and output ports of the device are individually and strictly verified to ensure that each channel functions normally. Depending on the specific type and application scenario of the device, load testing may also be conducted to simulate different load conditions and evaluate its stability and performance under various working conditions. Through these strict testing processes, it is ensured that the device can work stably and reliably in practical applications, providing solid guarantee for the stable operation of industrial production and helping enterprises achieve efficient and safe production goals.