Description

GE IS200HSLAH2ADE

I. Product Overview

II. Technical Parameters

Signal Processing Capability: Supports multiple signal types, including digital signals and analog signals, etc., depending on the type of connected devices. This enables it to flexibly adapt to the signal transmission requirements of different devices, and realize the effective integration and processing of various signals in complex industrial control systems. For example, in turbine control systems, it can receive analog signals from sensors such as temperature and pressure, as well as digital signals from control units, and perform corresponding processing and forwarding.

Electrical Characteristics: Electrical parameters such as working voltage, current, and power are determined according to the requirements of the entire system. In design, it has good electrical compatibility, can work stably under the given electrical conditions of the system, and has a certain tolerance for power fluctuations to adapt to the complex and changeable power environment in industrial fields, ensuring the stable operation of the module itself and the entire system.

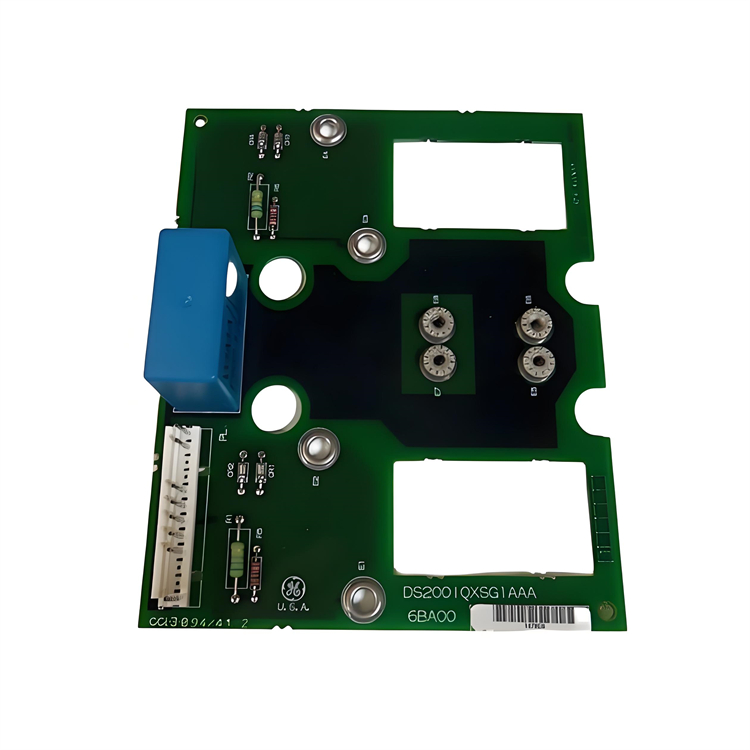

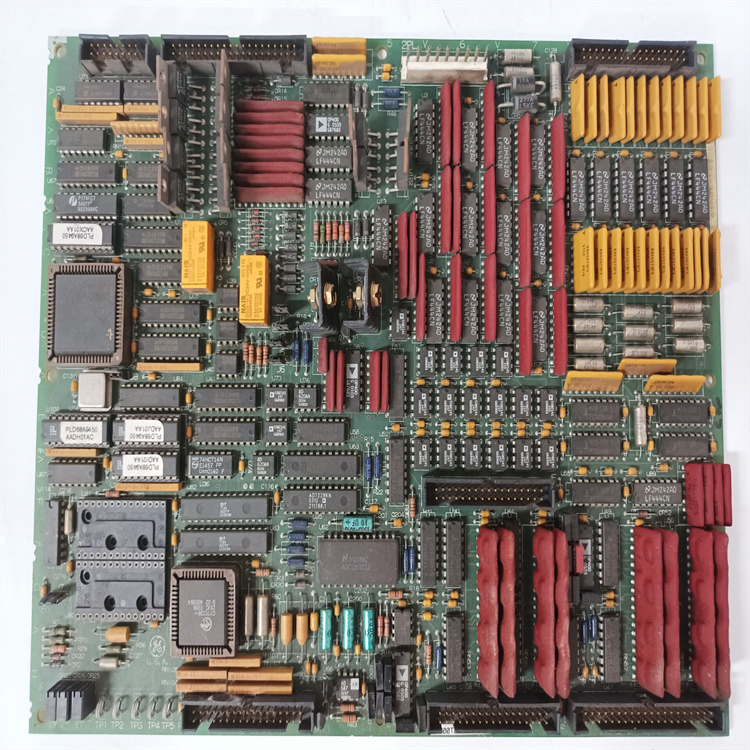

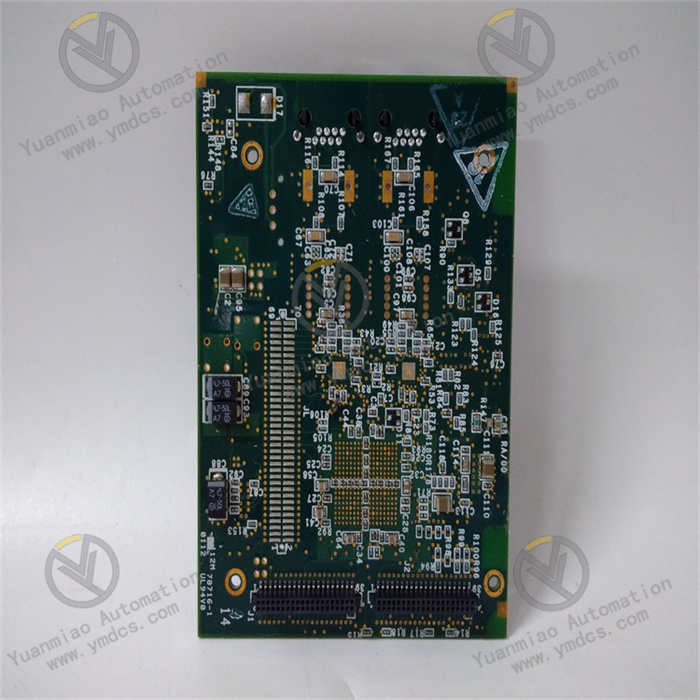

Hardware Composition: The circuit board is carefully designed in layout, with components distributed on both upper and lower surfaces. The top surface is provided with a jack connector, and the board is equipped with two Halo TG 110 - EO 50 N 5 transformers, six inductors, multiple transistors, a large number of resistors, capacitors, and diodes. More than twenty integrated circuits are distributed on it, including a Field-Programmable Gate Array (FPGA) located at position U1. The bottom surface is also provided with additional connectors, resistors, transistors, capacitors, and other components. These components work together to complete various functions such as signal processing and communication.

III. Functional Features

Modular Design: The modular design concept makes IS200HSLAH2ADE easy to install and maintain. In practical applications, if the module fails, technicians can conveniently disassemble and replace it, shortening the equipment downtime and reducing maintenance costs. At the same time, the modular design is also conducive to system upgrading and expansion, allowing users to flexibly adjust the system configuration according to actual needs.

Powerful Communication Function: By virtue of the HS SLR LNK interface, this module realizes high-speed and stable communication between different components in the system. It can quickly and accurately transmit a large amount of data, ensuring that various parameters during turbine operation, such as speed, temperature, and pressure, can be timely fed back to the control system, and at the same time, control commands can be accurately transmitted to the corresponding actuators, thereby realizing real-time monitoring and precise control of the turbine.

Signal Conversion and Processing: It can realize the conversion between different types of signals, converting the original signals collected by sensors into a format suitable for system processing and transmission. At the same time, it performs necessary processing and conditioning on the signals to remove noise interference, improve the quality and accuracy of the signals, provide reliable data support for the control system, and ensure the precision of turbine control.

Isolation Protection: Adopts advanced isolation technology to effectively isolate electrical interference between different circuits, improving the anti-interference ability and reliability of the system. In industrial fields, various electrical equipment will generate complex electromagnetic interference during operation. The isolation protection function can ensure that IS200HSLAH2ADE works normally in this environment, avoiding interference to signal transmission and system control.

Support for Customized Functions: It can usually be customized according to the specific needs of customers, with high flexibility. Different industrial application scenarios may have different requirements for turbine control systems. Through customized functions, this module can better meet the personalized needs of customers and provide targeted solutions.

IV. Application Scenarios

Power Plants: In thermal power plants, heavy-duty gas turbines and steam turbines are key equipment for power generation. GE IS200HSLAH2ADE is used in the control systems of these turbines to monitor and control the operating status of the turbines in real-time, ensuring stable and efficient power generation processes. For example, precisely control the speed of the turbine to match the speed of the generator, ensuring power quality; timely adjust the air intake and steam flow of the turbine according to load changes to realize flexible adjustment of power generation.

Substations: In some large substations, turbine-driven backup power systems may be used. IS200HSLAH2ADE plays an important role in this system, monitoring and controlling the turbine to ensure that the backup power can start and put into operation quickly and stably when the main power supply fails, ensuring the normal power supply of the substation.

Petrochemical Industry

Refineries: The refining process requires a lot of energy, and turbines are often used to drive various mechanical equipment such as compressors and pumps. GE IS200HSLAH2ADE ensures the stable operation of these equipment through precise control of the turbine, thereby ensuring the continuity and efficiency of the refining production process. For example, in crude oil distillation units, control the turbine-driven compressor to adjust the pressure in the distillation tower, ensuring that crude oil can be distilled and separated according to the predetermined process requirements.

Refineries: The refining process requires a lot of energy, and turbines are often used to drive various mechanical equipment such as compressors and pumps. GE IS200HSLAH2ADE ensures the stable operation of these equipment through precise control of the turbine, thereby ensuring the continuity and efficiency of the refining production process. For example, in crude oil distillation units, control the turbine-driven compressor to adjust the pressure in the distillation tower, ensuring that crude oil can be distilled and separated according to the predetermined process requirements.

Chemical Plants: In chemical production, many reaction processes require precise control of conditions such as temperature and pressure, and turbines are used to drive related equipment to meet these process requirements. IS200HSLAH2ADE can monitor and control the operating parameters of the turbine in real-time, and adjust in time according to changes in the chemical production process to ensure that chemical reactions are carried out under appropriate conditions, improving product quality and production safety.

Industrial Process Control

Metallurgical Industry: In the steel production process, key equipment such as blast furnace blowers are often driven by turbines. GE IS200HSLAH2ADE controls the turbine to ensure that the blower can stably provide sufficient air volume to maintain the combustion and smelting process in the blast furnace. At the same time, through cooperation with other automated control systems, it realizes optimal control of the entire steel production process, improving production efficiency and product quality.

Metallurgical Industry: In the steel production process, key equipment such as blast furnace blowers are often driven by turbines. GE IS200HSLAH2ADE controls the turbine to ensure that the blower can stably provide sufficient air volume to maintain the combustion and smelting process in the blast furnace. At the same time, through cooperation with other automated control systems, it realizes optimal control of the entire steel production process, improving production efficiency and product quality.

Paper and Food Processing Industries: In paper mills, turbines are used to drive equipment such as paper machines. IS200HSLAH2ADE can precisely control the operating speed and power of the turbine to ensure stability and uniformity in the paper production process. In food processing plants, turbines may be used to drive refrigeration equipment, conveying equipment, etc. This module can effectively control the turbine according to production needs, ensuring the smooth progress of the food processing process.

V. Common Problems and Maintenance

Repair and Refurbishment: If the module fails, a professional maintenance team can perform rapid testing, diagnosis, and repair. During the maintenance process, professional tools and equipment are used, and operations are carried out in a controlled environment. There is usually sufficient inventory of spare parts required for maintenance, and it is ensured that the replaced parts meet industrial-grade standards and their performance meets or exceeds the requirements of the Original Equipment Manufacturer (OEM). After maintenance, a comprehensive functional verification test will be conducted on the module to ensure that all its functions return to normal, and corresponding quality assurance services are provided. For some modules that have been used for a long time but are not completely damaged, refurbishment can extend their service life. The refurbishment process includes replacing aging and easily failing components, making TIL (Technical Improvement Upgrade) modifications as needed, reflow soldering the solder joints to eliminate cold solder joints, thoroughly cleaning the circuit board according to industrial standards, and applying a protective coating, etc.

Functional Verification Testing: To ensure the reliability of IS200HSLAH2ADE, functional verification testing is usually carried out in the actual OEM system setup. During the test, all inputs and outputs of the module are verified individually to ensure that each channel functions normally. Depending on the specific type of the module, load testing may also be performed to evaluate its stability and performance under different load conditions, thereby ensuring that the module can work stably and reliably in practical applications.