Description

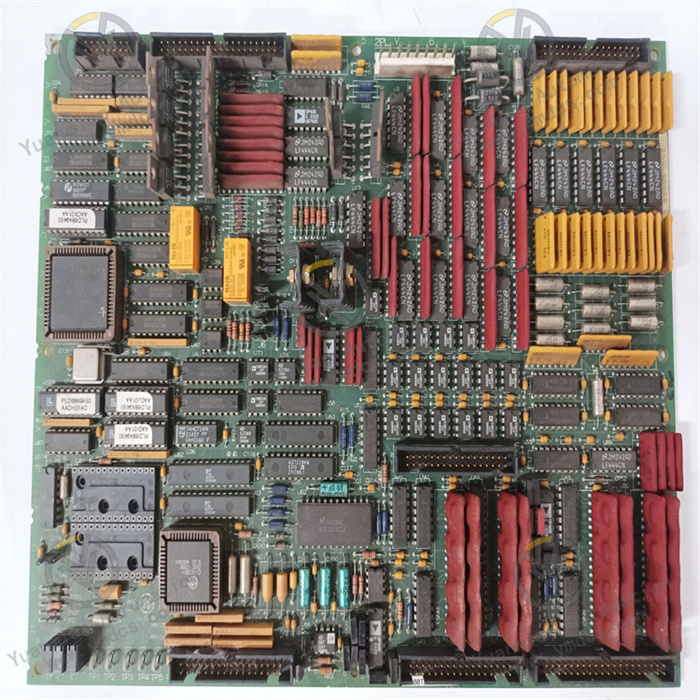

ABB PM862K02 3BSE081636R1

The ABB PM862K02 3BSE081636R1 is a redundant processor unit designed for the ABB AC 800M control system. It delivers high reliability, real-time performance, and scalability through its dual-CPU redundant architecture, multi-protocol communication capabilities, real-time control logic execution, and comprehensive fault tolerance mechanisms. Its working principle encompasses the entire process of data acquisition, arithmetic processing, communication interaction, and system management, making it a core component for "stable, efficient, and intelligent" control in modern industrial automation.

Hardware Components

- CPU:

Dual PM862 CPUs provide redundancy and failover capabilities, ensuring continuous operation of the control system even if a processor unit fails. Each CPU operates at 67MHz with 32MB of memory, capable of handling complex control tasks. - Communication Interfaces:

- Two RJ45 Ethernet ports (CN1, CN2) for connecting to the control network.

- Two RJ45 serial ports (COM3, COM4): COM3 is an RS-232C port with modem control signals; COM4 is isolated for configuration tools.

- CAN bus support for flexible device connectivity.

- Other Components:

Microprocessor, Random Access Memory (RAM), Real-Time Clock (RTC), LED indicators, initialization button, and Compact Flash interface.

Features & Advantages

- High Reliability:

Robust design with simple fault diagnosis, full EMC certification, IP20 protection, and stable operation in industrial environments. - Scalability:

Modular design allows step-by-step system expansion. - Excellent Communication:

Multi-protocol support (Ethernet, PROFIBUS DP, etc.) with redundant Ethernet ports for reliable data transmission. - Flexible Configuration:

Configurable via 800xA Control Builder for customized settings.

Technical Specifications

- Processor:

- CPU: MPC866 microprocessor, 67MHz clock frequency.

- Performance: 0.18ms for 1000 Boolean operations.

- Memory:

- RAM: 32MB (battery-backed for applications).

- Flash: 4MB Flash PROM (firmware storage), Compact Flash card (application and cold-start data).

- Communication Interfaces:

- Ethernet: Two RJ45 ports (CN1, CN2), IEEE 802.3 compliant, 10Mbit, supporting MMS and IAC. Recommended backbone: 100Mbit switched Ethernet.

- RS-232C: Two RJ45 serial ports (COM3, COM4): COM3 (75-19200 baud with modem control); COM4 (isolated, 9600 baud for configuration).

- Power Supply:

- Voltage: 24V DC (19.2-30V DC input range).

- Current: 210mA typical, 360mA max (excluding module bus and CEX-bus power).

- Power: 5.1W typical, 8.6W max (including all buses).

- Redundant Power: Supports redundant power status inputs (SA, SB), 30V max input voltage.

- I/O Characteristics:

- I/O Clusters: 1 electrical + 7 optical on non-redundant module bus; 7 optical on redundant bus.

- I/O Capacity: Up to 96 I/Os (single PM862) or 84 I/Os (redundant PM862).

- Bus Scan Rate: 0-100ms (depends on I/O module count).

- Physical Dimensions:

- Width: 119mm

- Height: 186mm

- Depth: 135mm

- Weight: 2800g

- Environmental Parameters:

- Operating Temperature: +5°C to +55°C

- Storage Temperature: -40°C to +70°C

- Humidity: 5-95% (non-condensing)

- Altitude: 2000m max

- Protection Class: IP20

- Other Features:

- Clock Synchronization: 1ms precision via CNCP protocol.

- OPC Client: Up to 3000 events in the event queue.

- OPC Server Speed: 36-86 events/sec, 113-143 data messages/sec.

- CEX Bus: 12 modules supported, 2.4A max power current.

Working Principle

The PM862K02 executes control logic, data processing, communication coordination, and system management through the following mechanisms:

1. Hardware Architecture & Component Coordination

- Dual-CPU Redundancy:

Active/Standby CPUs with real-time synchronization via high-speed internal bus. - Communication Interfaces:

Ethernet (redundant paths), serial ports (isolated COM4), and CAN bus for I/O modules. - Storage & Clock:

Compact Flash for firmware/programs; RTC for precise time stamping.

2. Control Logic Execution Flow

- Data Acquisition:

Scans I/O modules, preprocesses analog/digital signals (filtering, linearization). - Logic Processing:

Executes PID control, safety interlocks, and data analysis based on IEC 61131-3 programming. - Output Control:

Converts results to analog/digital signals with output validation and fault protection.

3. Communication Mechanisms

- Industrial Ethernet:

Modbus TCP, PROFIBUS DP, and ABB proprietary protocols with redundant links. - Serial Communication:

RS-232/RS-485 with isolation for legacy devices. - CAN Bus:

CANopen protocol for high-speed I/O data transfer.

4. Redundancy & Fault Handling

- Hot Standby Switching:

Automatic failover in <50ms upon detection of faults (e.g., watchdog timeout). - Self-Diagnosis:

Continuous monitoring of CPU, memory, and I/O connections with LED/alarm indicators. - EMC Protection:

Isolated power, shielded enclosure, and filtering for industrial environments.

5. System Management

- Firmware Updates:

Remote upgrade via Ethernet (FTP/HTTP). - Time Synchronization:

NTP or hardware clock for event logging consistency. - Event Logging:

Stores critical operations (program downloads, faults) for auditing.

Typical Applications

- Process Industry:

Closed-loop temperature/pressure control for reactors; safety interlock systems for refineries. - Power Systems:

Turbine speed control; substation automation. - Manufacturing:

Robot coordination; precision motion control. - Energy Management:

Microgrid control; HVAC optimization in smart buildings.

Other Brand-Related Products

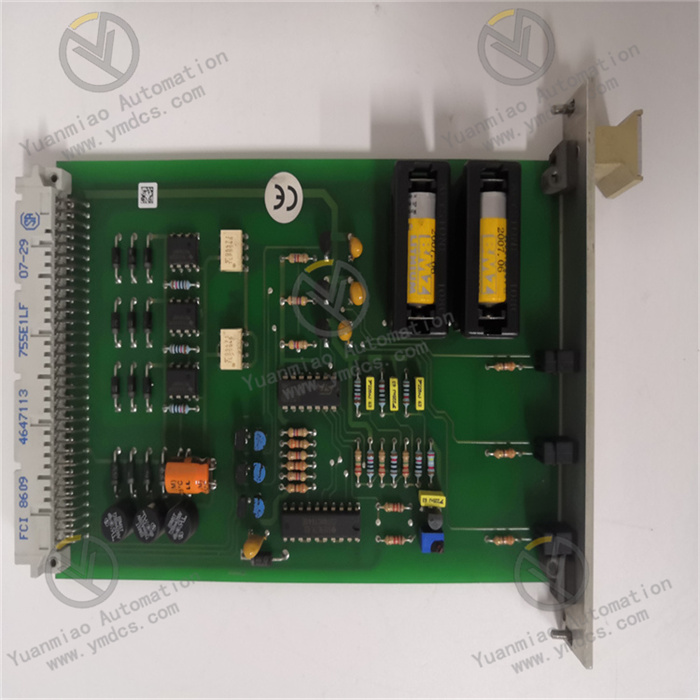

GE IS200TRPGH1BDD Trip Solenoid Control Board

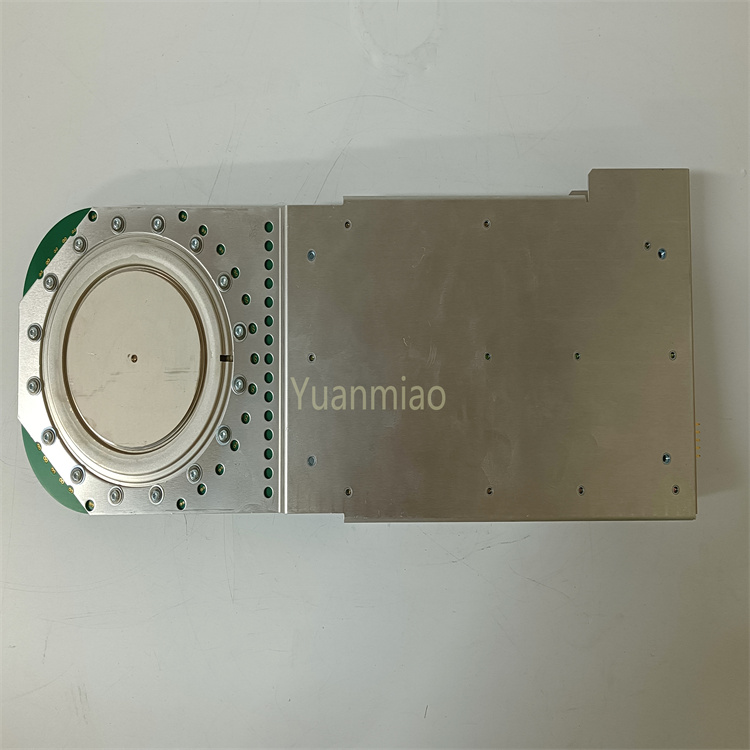

Bently Nevada 1900/65A-01-01-01-00-00 | 1900/65A General Purpose Equipment Monitor

TRICONEX AI2351 7400210-010 Input/Output Module

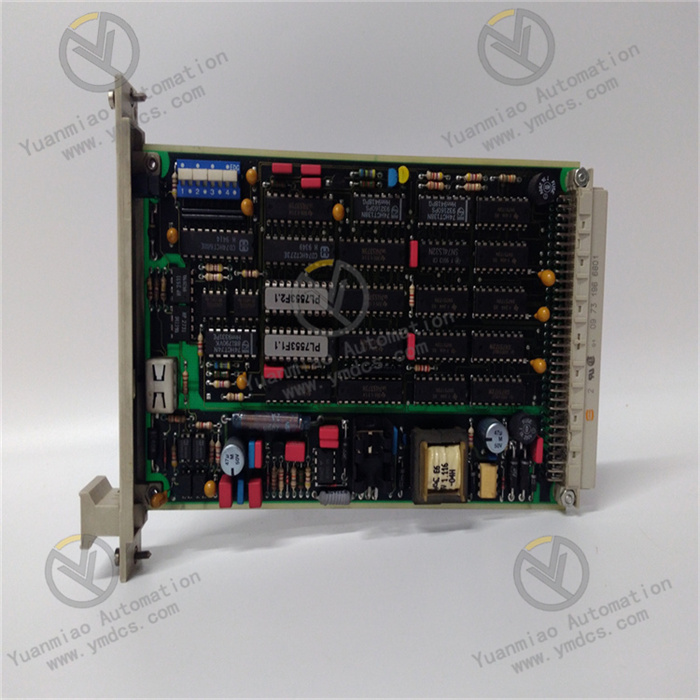

Woodward 5466-1035 | MicroNet CPU5200

Schneider 140ACO13000 | Analog Output Module