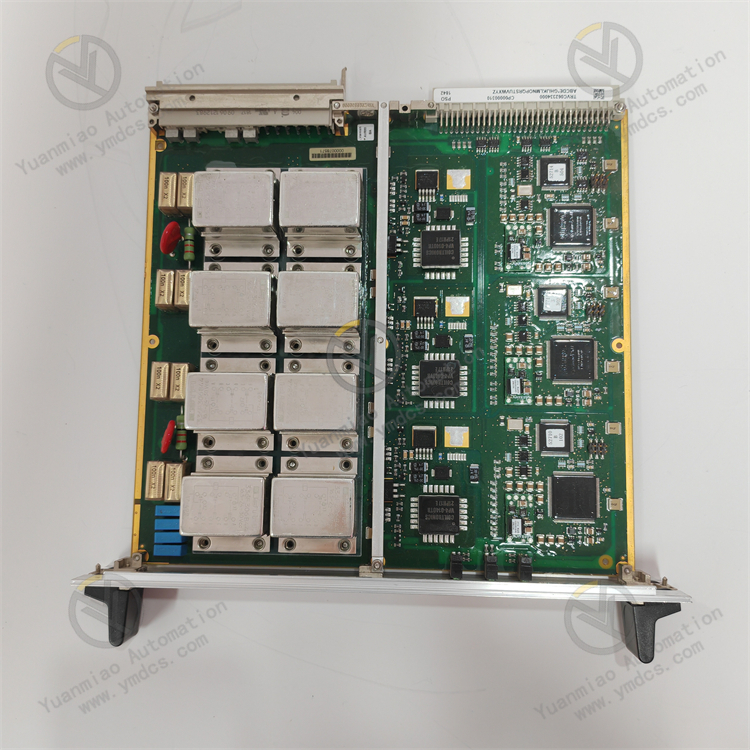

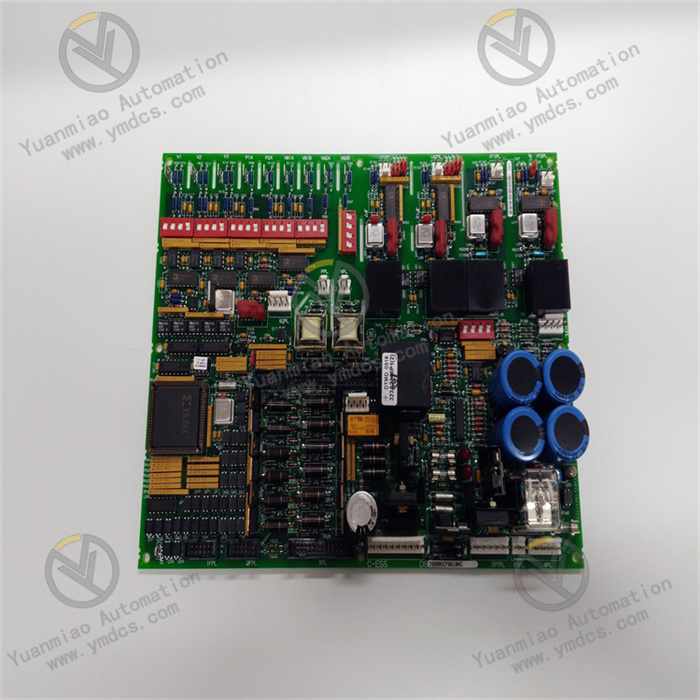

Description

Basic Information

Brand: ABB

Model: PM866AK01

Order Number: 3BSE076939R1

Type: High-performance industrial automation controller (belongs to ABB AC 800M series, typically serves as the central processing unit CPU for PLC/DCS systems).

Application Scenarios: Suitable for complex industrial control systems requiring high reliability and real-time performance, such as process automation, energy management, machinery manufacturing, rail transit, and other fields.

Model: PM866AK01

Order Number: 3BSE076939R1

Type: High-performance industrial automation controller (belongs to ABB AC 800M series, typically serves as the central processing unit CPU for PLC/DCS systems).

Application Scenarios: Suitable for complex industrial control systems requiring high reliability and real-time performance, such as process automation, energy management, machinery manufacturing, rail transit, and other fields.

Functional Features

1. High-Performance Processing Capability

- Processor: Typically equipped with a multi-core processor (such as ARM or PowerPC architecture) with a higher main frequency (up to GHz level), supporting faster logic operations, data processing, and complex algorithms (such as PID control, motion control, machine learning edge computing, etc.).

- Real-Time Performance: Supports hard real-time operating systems (such as ABB's RP-110 real-time kernel) to ensure microsecond-level response speed, meeting the stringent real-time control requirements of industrial sites.

- Memory Configuration: Equipped with large-capacity RAM and flash memory (on the order of several GB), supporting the storage of large control programs, historical data, and user-defined algorithms.

2. Rich Communication and Integration Capabilities

- Industrial Communication Protocols:

- Standard dual Ethernet ports support mainstream industrial Ethernet protocols such as PROFINET, Ethernet/IP, Modbus TCP, and OPC UA, compatible with digital factory and industrial internet (IIoT) architectures.

- Supports traditional fieldbus protocols (such as PROFIBUS, CANopen, etc., requiring expansion modules), facilitating connection to legacy devices.

- Network Redundancy: Supports ring network topology and redundant communication (such as PRP/HSR protocols) to ensure stable system operation during network outages.

- Remote Access: Built-in Web server supports remote monitoring and configuration via a browser; compatible with remote download and online debugging functions of the ABB AC 800M system.

3. Flexible Expandability and Redundancy Design

- I/O Expansion: Connects to ABB S800 I/O modules (such as DI/DO, AI/AO, counters, temperature modules, etc.) via the CEX bus, supporting the expansion of hundreds of I/O points to adapt to control systems of different scales.

- Redundancy Configuration:

- Supports dual CPU hot standby redundancy (requires matching redundancy modules), with real-time data synchronization between primary and standby controllers and automatic switching during faults to ensure uninterrupted system operation.

- Supports power supply redundancy and communication redundancy to enhance overall reliability.

4. Industrial-Grade Reliability and Protection

- Environmental Adaptability:

- Operating temperature range: -40°C ~ +70°C (wide-temperature design, adapting to harsh industrial environments).

- Protection level: IP20 (suitable for installation in control cabinets), resistant to vibration, impact, and electromagnetic interference (compliant with standards such as IEC 61000).

- Fault Diagnosis:

- Built-in self-diagnostic function, with real-time status display via LED indicators (such as power, operation, communication, fault).

- Supports error log recording and alarm output, facilitating quick location of communication faults, module failures, or program anomalies.

5. Programming and Configuration

- Software Compatibility: Uses ABB Control Builder M or 800xA system software for programming and configuration, supporting IEC 61131-3 standard programming languages (Ladder Diagram LD, Structured Text ST, Function Block Diagram FBD, etc.).

- Advanced Functions: Supports C/C++ custom algorithm integration to meet special control requirements; supports online firmware upgrades for convenient function expansion and vulnerability repair.

Technical Parameters

| Parameter | Description |

|---|---|

| Processor | Multi-core processor (such as ARM Cortex-A or PowerPC), main frequency ≥ 1 GHz |

| Memory | RAM: 4 GB or higher; Flash: 8 GB or higher (supports SD card expansion) |

| Communication Interfaces | 2×10/100/1000 Mbps Ethernet ports (RJ45), supporting PROFINET IO controllers |

| Power Supply Voltage | DC 24V (range: 19.2~30V DC), supporting redundant power input |

| Expansion Bus | CEX bus (for connecting I/O modules), supporting a maximum transmission rate of 128 Mbps |

| Dimensions | Compact design (e.g., width approx. 40 mm, height approx. 150 mm), standard DIN rail mounting |

| Real-Time Clock | Built-in battery-backed clock, supporting time retention during power outages |

| Certifications | CE, UL, ATEX (explosion-proof certification, suitable for hazardous areas), DNV GL (maritime certification), etc. |

Supporting Systems and Applications

Series Affiliation: AC 800M controller series, which can be seamlessly integrated with ABB's 800xA automation system to achieve end-to-end management from field devices to the cloud.

Typical Applications:

Typical Applications:

- Process Industry: Complex process control in chemical, oil & gas, power, metallurgy, and other fields (such as distillation column control, boiler control).

- Discrete Manufacturing: Robot control, production line automation, precision machinery processing systems.

- Energy and Infrastructure: Smart grids, rail transit signaling systems, sewage treatment plant monitoring.

Differences from PM861AK02 (for Reference)

- Performance Positioning: As a higher-tier model, PM866AK01 surpasses PM861AK02 in processor performance, memory capacity, and communication speed, making it suitable for handling large data volumes and high-complexity tasks.

- Redundancy Support: PM866AK01 may natively support more flexible redundancy configurations (such as faster hot standby switching), while PM861AK02 requires additional modules to achieve redundancy.

- Expandability: PM866AK01 may support more I/O modules or higher-speed expansion buses, adapting to larger-scale systems.

Operation Guide for ABB PM866AK01 3BSE076939R1

Installation

- Rail Mounting: Use a unique sliding and locking mechanism to install the module on a standard DIN rail, ensuring a secure fit.

- Power Connection: Connect a 24V DC power supply (voltage range: 19.2–30V DC), ensuring correct positive and negative connections.

- Communication Port Connection: The baseplate has two RJ45 Ethernet ports (CN1, CN2) for connecting to the control network to enable data communication. There are also two RJ45 serial ports (COM3, COM4), where COM3 is an RS-232C port with modem control signals, and COM4 is isolated for connecting configuration tools.

Configuration and Parameter Setting

- Hardware Configuration: If using the CPU redundancy function, correctly connect redundancy components such as CEX-Bus extension cables as per the manual, and ensure all components are operational. For connected I/O modules, set parameters such as addresses.

- Software Configuration: Use ABB's 800xA Control Builder software for configuration. Set the controller's communication parameters in the software, such as IP address, subnet mask, gateway, etc., for the Ethernet interface, as well as real-time clock parameters and memory allocation parameters. Meanwhile, write control programs according to specific control tasks, which can use programming languages compliant with the IEC 61131-3 standard, such as Ladder Diagram LD and Structured Text ST, and download them to the controller.

Operation and Monitoring

- Startup and Status Check: After powering on the controller, check the operating status via LED indicators, such as power indicator, run indicator, and communication indicator. Normally, the power indicator remains on, the run indicator flashes to show the controller is executing programs, and the communication indicator flashes or remains on according to the communication status.

- Real-Time Monitoring: Use host computer monitoring software or related operation interfaces to real-time monitor the controller's operating status and data, including CPU usage, memory occupancy, input/output values of I/O modules, and execution results of control programs. Alarm thresholds can also be set to issue alarms when parameters exceed normal ranges.

- Remote Operation: If the system supports remote control, the PM866AK01 can be operated via the network, such as remotely modifying parameters, starting or stopping control programs, and remote reset.

Maintenance and Fault Handling

- Routine Maintenance: Regularly inspect the controller's operating status, including LED indicators, and clean the device surface of dust. Check the battery status; if an internal lithium battery is used, replace it in a timely manner when the battery level is low; if there is an external backup battery, check its connection and test its performance regularly.

- Fault Diagnosis: When a fault occurs, first check the status of the LED indicators, and make a preliminary judgment of the cause by referring to the fault code table in the manual based on the flashing pattern or color change. You can also use the controller's built-in diagnostic functions or related diagnostic software to obtain detailed fault information by viewing error logs, diagnostic register values, etc. Common faults include communication failures, power supply faults, I/O module faults, and program execution errors. Take corresponding solutions for different fault causes, such as checking communication lines, replacing faulty modules, and modifying program errors.