Description

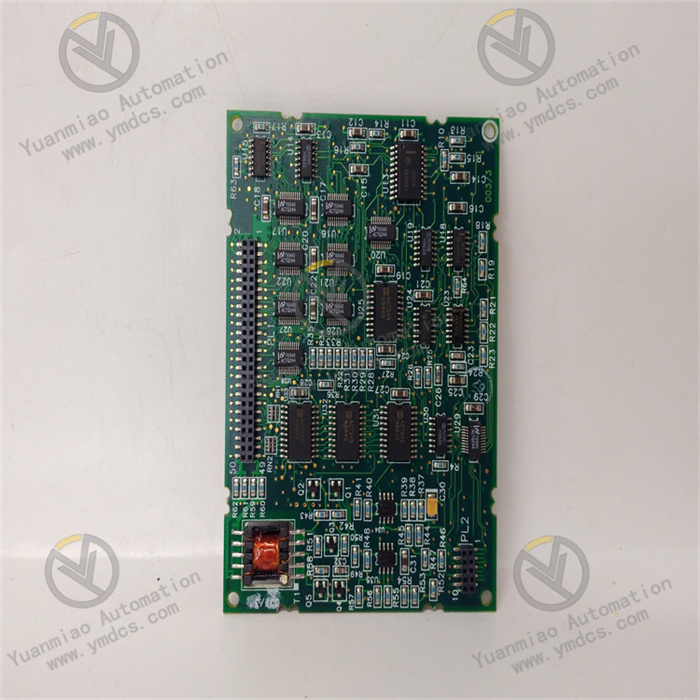

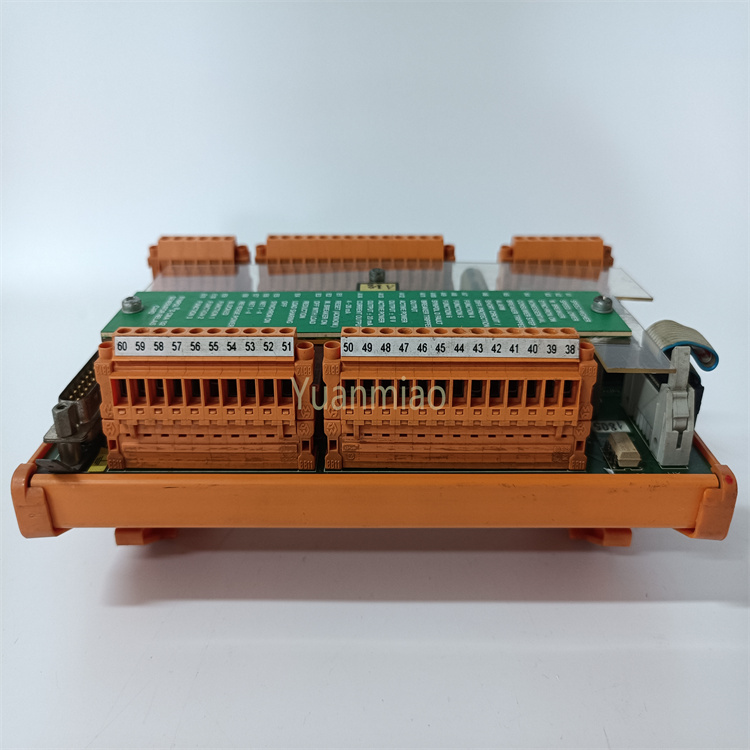

GE IC660ELB912

I. Overview

GE IC660ELB912 is a high-performance network interface module, belonging to the Genius I/O series products of GE Fanuc (now part of its business belongs to fields such as Emerson Automation). It plays a key bridging role in industrial automation systems, mainly used to realize the connection between the user's microprocessor system and the GE µGENI network, thereby achieving efficient data communication and remote control between devices. With its excellent performance and stable performance, this module is widely used in various complex industrial scenarios, providing solid support for the intelligent and automated process of industrial production.

II. Technical Parameters

- Electrical Parameters: The power supply adopts 5V DC voltage, which is compatible with the power configuration of most industrial control systems to ensure stable power supply. In terms of current consumption, it is approximately 1.0 ampere under single-channel PCIM, and when it is a dual-channel PCIM with 2 sub-boards, the current consumption increases to 1.5 amperes. Each input channel is sensitive to current, and only a small current change is needed to accurately identify the change of signal state, ensuring efficient response to various input signals. The module has good electrical isolation performance, which can effectively resist external electrical interference, ensure the purity and accuracy of data transmission, and can work stably even in industrial sites with complex electromagnetic environments.

- Physical Parameters: The product has a compact shape, with dimensions of approximately 88.9mm × 68.6mm × 25.4mm and a weight of only 0.2kg. This lightweight and small design allows it to be easily installed inside equipment with limited space such as control cabinets and distribution boxes, without occupying too much valuable space, facilitating the layout and integration of industrial electrical systems. The shell is made of strong and durable materials, which not only has excellent electrical insulation performance, can effectively prevent the risk of electric leakage, but also has certain mechanical strength, can withstand a certain degree of vibration and impact, and reliably protect the internal precision circuits.

- Environmental Parameters: The operating temperature range is -10°C to +50°C, and it can work normally in a relatively wide temperature environment. Whether it is industrial facilities in cold regions or production workshops in high-temperature environments, it can operate stably without being affected by large temperature fluctuations. The relative humidity adaptation range is 5%-95% (non-condensing), which means it can work normally in humid coastal industrial sites or dry inland factory environments, effectively avoiding circuit short circuits, corrosion and other faults caused by humidity issues, and greatly improving the applicability of the module in industrial environments in different regions.

- Communication Parameters: It supports Genius I/O network communication and can seamlessly connect with other devices. The communication rate has multiple configurable options, such as 38.4K, 76.8K, 153.6K standard rates, and can even be extended to 153.6K. Users can flexibly adjust according to the needs of actual industrial application scenarios. The network address also supports configuration, with a range of 1-77, facilitating accurate identification and positioning in complex network environments. In addition, it supports a variety of mainstream industrial communication protocols, such as Modbus TCP/IP, Profibus DP, etc., and can conveniently communicate with various PLCs, DCS control systems and other intelligent devices to achieve rapid data transmission and sharing.

III. Functional Characteristics

- Efficient Data Communication: As a network interface module, IC660ELB912 can transmit data between devices quickly and accurately. Through the Genius I/O network, it can communicate with up to 30 bus devices, providing real-time and comprehensive equipment status data for the control system, and helping to efficiently monitor and precisely control the production process. In industrial automated production lines, it can timely feedback the operating status of equipment at each workstation, helping the system make adjustments quickly and ensuring the smooth operation of the production line.

- Powerful Equipment Control: It can realize effective control of remote I/O devices, accurately transmit the control commands of the user's microprocessor system to on-site equipment, such as sensors and actuators, meeting the remote control needs in complex industrial automation scenarios. In the automated production process of large factories, it can remotely control the start and stop of equipment, adjust operating parameters, etc., improving production efficiency and management level.

- Flexible Configuration Options: Parameters such as communication rate and network address can be flexibly configured to meet the requirements of different industrial network environments. Whether it is a new industrial automation system or an upgrade and transformation of an existing system, it can be easily integrated to provide users with personalized solutions. Users can adjust the working parameters of the module through simple setting operations according to actual project needs to achieve the best collaborative work with other devices.

- High Reliability Design: It adopts industrial-grade design standards, and both hardware selection and circuit layout have undergone strict consideration and testing. It has good anti-interference ability. At the hardware level, high-quality electromagnetic shielding materials are used to block external electromagnetic radiation from interfering with internal circuits; in circuit design, filter circuits, isolation circuits and other technologies are used to preprocess input signals, remove clutter and interference signals, and ensure that the signals transmitted to the control system are true and reliable. Even in strong electromagnetic interference environments such as steel smelting and chemical production, it can still work stably, ensuring the normal operation of the industrial automation system.

- Convenient Diagnosis and Maintenance: The module has a built-in self-diagnosis system, which can monitor its own operating status in real-time, including power supply and communication connections. Once an abnormal situation is detected, such as communication failure or abnormal power voltage, it will immediately send alarm information through indicator lights or communication interfaces, facilitating technicians to quickly locate and solve problems. Its intuitive indicator light design, where each key function corresponds to a status indicator light, allows technicians to intuitively understand the working status of the module through the on and off of the indicator lights, simplifying the daily inspection and maintenance workflow and reducing maintenance costs.

IV. Application Scenarios

- Industrial Automated Production Lines: In automated production lines of industries such as automobile manufacturing and electronic equipment processing, it is used to connect various equipment, such as robots, sensors, controllers, etc., to realize data exchange and collaborative work between equipment, ensuring the efficient and stable operation of the production line. By precisely controlling the actions of equipment at each workstation, production efficiency and product quality are improved.

- Power System Automation: It is applied to the automation control systems of power facilities such as power plants and substations to realize remote monitoring and control of power equipment. It collects equipment operating data in real-time, such as voltage, current, temperature and other parameters, detects equipment faults in a timely manner and handles them, ensuring the safe and reliable power supply of the power system.

- Process Control Field: In process industries such as chemical industry, food and beverage, and pharmaceutical industry, it conducts real-time monitoring and control of parameters such as temperature, pressure, and flow during the production process. Through connection with on-site sensors and actuators, the collected data is transmitted to the control system, and precise control is carried out according to preset process parameters to ensure the stability and consistency of product quality.

- Smart Factory Construction: As an important part of the smart factory network architecture, it communicates with other smart devices and systems to realize comprehensive intelligent management of the factory production process. Through real-time data collection and analysis, it optimizes production processes, improves resource utilization, reduces production costs, and enhances the overall competitiveness of the factory.

V. Common Faults and Solutions

- Communication Faults: It is manifested as communication interruption or data transmission errors between the module and other devices. One possible reason is that the communication cable connection is loose or damaged. The solution is to carefully check the connection condition of the communication cable, ensure that the plug is tightly inserted, and replace it in time if there is any damage to the cable. The second is that the communication parameters are set incorrectly. At this time, it is necessary to carefully check the communication protocol, baud rate, station address and other parameters between the module and the connected device to ensure that they are completely consistent. Thirdly, in case of strong electromagnetic interference, measures such as shielding communication cables, keeping them away from large motors, transformers and other strong electromagnetic sources, and installing filters when necessary can be taken to enhance the anti-interference ability and ensure the stability of communication.

- Power Faults: The module cannot start normally, and the power indicator is not on. First, check whether the power connection is firm to ensure that the power cord is connected correctly; then use a multimeter to measure the power input voltage to confirm whether it is within the working voltage range specified by the module. If the power voltage is abnormal, check whether there is a fault in the power supply system; if the power connection and voltage are normal, the internal power circuit of the module may be damaged and needs to be repaired or replaced.

- Device Connection Faults: Failure to establish an effective connection with other devices may be due to a network address setting conflict. Recheck and set the network address of the module to ensure its uniqueness in the network; it may also be that the device driver is not installed correctly or is outdated. Update the device driver to the latest version; if it is a hardware connection problem, check the physical connection lines between devices to ensure correct and firm connection.

- Abnormal Data Transmission: Data loss, errors, etc. occur during transmission. It may be that the communication rate is set too high, exceeding the bearing capacity of the device. Appropriately reduce the communication rate and observe whether the data transmission returns to normal; it may also be that the module memory is insufficient, leading to abnormal data caching. Clean up the module memory or increase the memory capacity; if it is suspected that the module hardware failure causes abnormal data processing, professional personnel are required to detect and repair the module.