Description

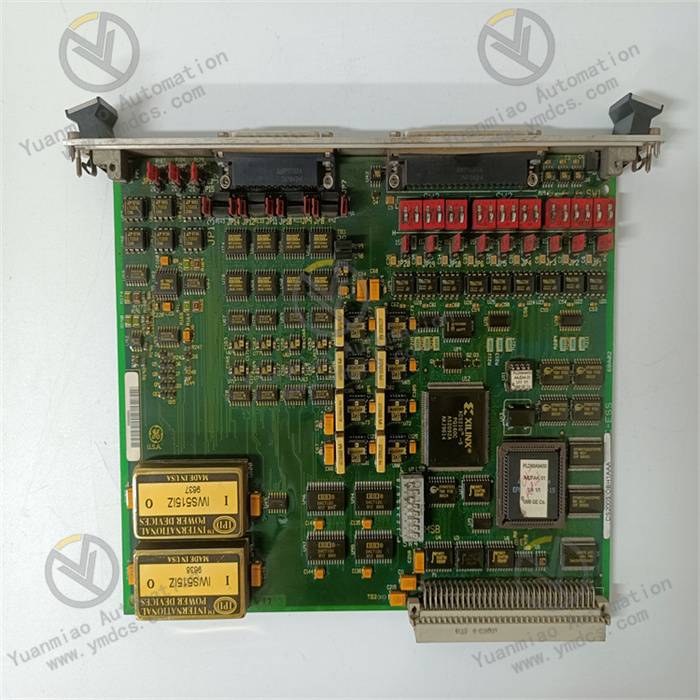

GE IC693ALG223D

I. Overview

GE IC693ALG223D is a high-performance analog input module in the GE Fanuc 90-30 series, mainly used for collecting and processing various analog signals in industrial automation control systems. In industrial production processes, many key parameters such as temperature, pressure, flow, and liquid level exist in the form of analog quantities. This module can accurately convert these continuously changing analog signals into digital signals and transmit them to PLCs and other control devices for analysis and processing. It serves as an important bridge connecting on-site sensors and control systems, playing an indispensable role in the field of industrial automation.

II. Technical Parameters

- Input Channels: Equipped with 8 independent analog input channels, each of which can be independently configured. It can collect multiple different types of analog signals simultaneously, meeting the needs of multi-parameter monitoring in industrial sites. The channels are isolated from each other, effectively avoiding signal interference between channels and ensuring the accuracy of signal collection.

- Input Signal Types: Supports various common analog input signal types, including 4-20mA DC current signals and 0-10V DC voltage signals. These two signal types are widely used in industrial fields and are compatible with various sensors, transmitters, and other devices, such as 4-20mA signals output by pressure transmitters and 0-10V signals converted by temperature sensors through transmitters.

- Resolution: It has a relatively high resolution, usually 12 bits, which can accurately capture subtle changes in analog signals, ensuring that the collected data has high precision. The high resolution enables the module to accurately reflect the changing trend of signals even when the measurement range is small, providing more accurate original data for the control system.

- Accuracy: Under certain environmental conditions, the measurement accuracy is high, with an error generally within ±0.1% of the full scale. This means that the deviation between the data collected by the module and the actual signal value is small, which can provide a reliable guarantee for control decisions and reduce the problem of reduced control accuracy caused by measurement errors.

- Isolation Performance: It has good electrical isolation performance. The input signal and the backplane bus adopt an isolation design, and the isolation voltage can reach a certain value (such as 2500V AC). It can effectively resist common-mode interference and differential-mode interference in industrial sites, ensuring the stability and accuracy of signal collection, especially in complex electromagnetic environments.

- Power Requirements: It is usually powered by the backplane bus of the PLC system, with an operating voltage of 5V DC and low current consumption, which will not cause excessive burden on the system power supply, ensuring the stable operation of the module in the system.

- Environmental Parameters: The operating temperature range is 0°C to 60°C, which can adapt to temperature changes in industrial sites and work normally in high-temperature workshops or low-temperature control rooms. The relative humidity adaptation range is 5%-95% (non-condensing), which can operate reliably in humid environments and prevent circuit failures caused by humidity issues. At the same time, it has a certain anti-vibration and anti-shock capability, meeting the environmental requirements of industrial-grade equipment.

- Physical Parameters: The module has a compact size design, is compatible with other modules in the 90-30 series, and is easy to install and integrate in the control cabinet, saving installation space. It adopts a standard module structure, is light in weight, and is convenient for installation and maintenance.

III. Functional Characteristics

- High-Precision Signal Collection: With the characteristics of high resolution and high precision, GE IC693ALG223D can accurately collect analog signals in industrial sites. Whether it is a slowly changing temperature signal or a rapidly changing pressure signal, it can be accurately captured, providing real and reliable original data for the control system and ensuring the scientificity and accuracy of control decisions.

- Flexible Channel Configuration: The 8 input channels can be independently configured according to actual needs, and each channel can be set to different signal types (4-20mA or 0-10V) respectively, meeting the needs of collecting different types of analog signals in industrial sites. This flexible configuration method enables the module to adapt to diverse application scenarios, improving the adaptability and flexibility of the system.

- Strong Anti-Interference Ability: Adopting advanced filtering technology and isolation design, it can effectively suppress electromagnetic interference, radio frequency interference, etc. in industrial sites. The filtering circuit can smooth the input signal and remove high-frequency noise in the signal; electrical isolation avoids interference between different channels and between input signals and the control system, ensuring the purity of the collected signals and improving the reliability of the module in complex industrial environments.

- Self-Diagnosis Function: It has a complete self-diagnosis capability and can monitor the working status of the module itself in real time, such as channel faults and power abnormalities. When an abnormal situation is detected, the fault information will be fed back to the control system through corresponding status indicators or communication interfaces, facilitating technicians to discover and troubleshoot faults in a timely manner, reducing system downtime and improving maintenance efficiency.

- Seamless Integration with the System: As part of the 90-30 series, IC693ALG223D has good compatibility with CPU modules, power modules, etc. of this series, and can be seamlessly integrated into the 90-30 series PLC system. The module communicates with the CPU module through the backplane bus, with fast data transmission speed and high reliability, ensuring that the collected analog signals can be timely transmitted to the CPU for processing.

IV. Common Faults and Solutions

- Inaccurate Signal Collection

- Phenomenon: The collected analog data deviates greatly from the actual signal value, exceeding the allowable error range, causing the control system to make wrong control decisions.

- Possible Causes: Poor contact, open circuit, or short circuit in the input signal line, leading to abnormal signal transmission; loss or error of module channel calibration parameters; faults in the internal signal conditioning circuit of the module, such as damage to the operational amplifier and failure of the filter capacitor; excessive external interference affecting the normal signal collection.

- Solutions: Check the connection of the input signal line to ensure that the line is firmly connected without open or short circuits, and replace the signal line if necessary; re-calibrate the module channel, and perform calibration operations using a standard signal source in accordance with the calibration procedures; if it is still inaccurate after calibration, there may be an internal circuit fault, and it is necessary to contact professionals for maintenance or replace the module; take measures such as strengthening shielding and keeping away from interference sources to reduce the impact of external interference on signal collection.

- No Signal Input in Channels

- Phenomenon: One or more channels cannot collect signals, the displayed value is a fixed value (such as zero or full scale), and the corresponding signal indicator has no response.

- Possible Causes: The external sensor or transmitter corresponding to the channel is faulty and cannot output signals; the signal line is disconnected, resulting in the signal being unable to be transmitted to the module; the input circuit of the channel inside the module is damaged, such as damage to the channel switch tube and fuse blowout.

- Solutions: Check the external sensor or transmitter, judge whether it is normal by means of replacement or detecting its output signal, and repair or replace it if it is faulty; check the signal line, repair the broken point or replace the line; if both the sensor and the line are normal, there may be an internal fault in the module channel, and the module needs to be repaired or replaced.

- Module Communication Fault

- Phenomenon: The module cannot communicate with the CPU module, the CPU cannot obtain the data collected by the module, or the module status information cannot be uploaded to the CPU.

- Possible Causes: Poor connection between the module and the backplane bus, such as the module not being plugged in tightly, loose or oxidized bus interface; backplane bus fault; fault in the internal communication circuit of the module.

- Solutions: Re-plug the module to ensure that the module is firmly connected to the backplane bus, and clean the oxide layer of the bus interface; check the backplane bus, if other modules also have communication problems, it may be a bus fault, and the bus needs to be repaired or replaced; if only this module has a communication fault, there may be a fault in the internal communication circuit, and the module needs to be repaired or replaced.

- Abnormal Module Indicators

- Phenomenon: The status indicators such as the power indicator and fault indicator of the module are abnormal, such as the power indicator not being on and the fault indicator being always on.

- Possible Causes: Abnormal power supply of the module, such as no power supply, insufficient power voltage; fault in the internal power circuit of the module; the module detects its own fault, such as abnormal internal circuit.

- Solutions: Check the power connection of the module to ensure that the power supply is normal and the voltage meets the requirements; if the power supply is normal, there may be a fault in the internal power circuit of the module, which needs to be repaired; if the fault indicator is always on, check the specific fault cause in combination with the self-diagnosis information and take corresponding measures, and replace the module if necessary.