Description

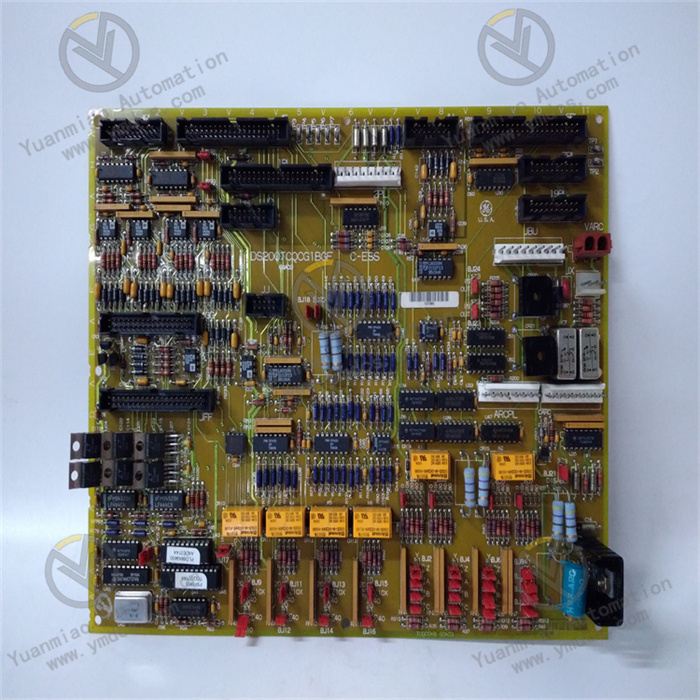

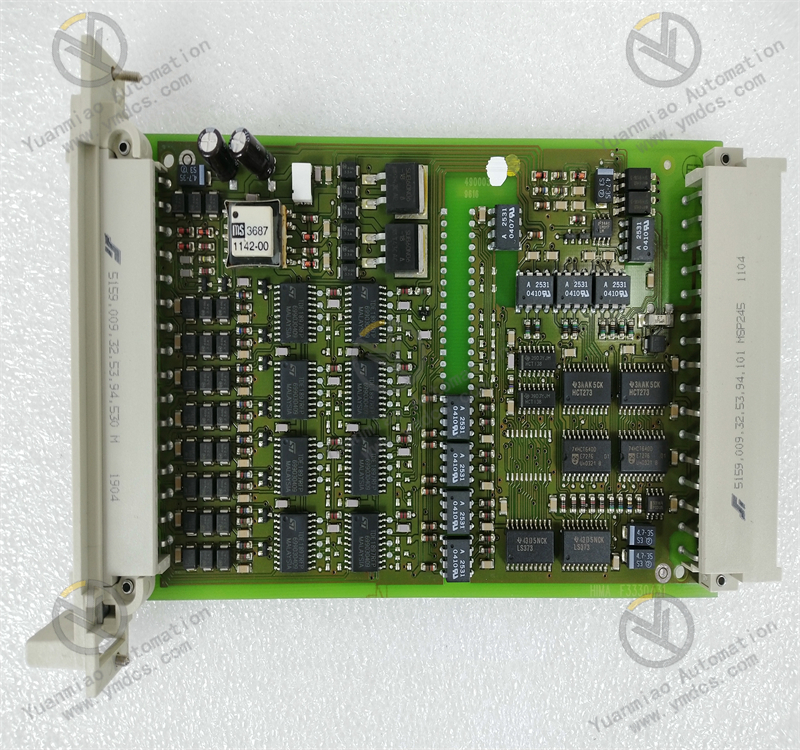

GE IC693CPU350-BC

I. Product Overview

GE IC693CPU350-BC is a high-performance central processing unit module in the GE Fanuc 90-30 series, designed specifically for small and medium-sized industrial automation control systems. As the core component of the system, it undertakes key tasks such as program execution, data processing, I/O control, and communication coordination between devices. With balanced performance and reliable operation, this module can meet the control needs of various industrial scenarios. Whether it is the logic control of production lines or the adjustment of process parameters, it can complete the tasks stably and efficiently. It is an important device to improve the level of industrial automation control, widely used in machinery manufacturing, food processing, packaging equipment and other fields.

II. Technical Parameters

- Processor Performance: Equipped with a 32-bit microprocessor, the basic logic instruction execution time is about 0.2μs, which can quickly respond to control needs. It supports multi-task processing and can run logic control, data acquisition and other tasks at the same time to ensure efficient operation of the system.

- Memory Configuration: The user program memory is 1MB flash memory, which can store a large number of user programs and system configurations, and the data is not easy to lose; the data memory is 1MB SRAM, equipped with a battery backup function, which can save key data in case of power failure, ensuring that the system can quickly resume operation after restart.

- I/O Support: It can support up to 8 local I/O modules, and can connect to remote I/O systems through expansion. The maximum number of digital I/O points can reach 16384, and the number of analog I/O points can reach 1024, which can meet the input and output needs of small and medium-sized control systems.

- Communication Interfaces: Built-in 1 RS-232 port for programming debugging and communication with a small number of devices; 1 DH+ interface, which supports the establishment of communication networks with other 90-30 series modules or devices, with a maximum transmission rate of 125kbps, facilitating data sharing within the system.

- Power Requirements: Powered by the system backplane bus, the working voltage is 5V DC, the typical power consumption is about 8W, which has little burden on the power supply system and can stably adapt to the power modules of the 90-30 series.

- Environmental Parameters: The working temperature range is 0°C to 60°C, which can work normally in the common temperature fluctuation environment of industrial sites; the relative humidity is 5%-95% (non-condensing), which can adapt to humid environments; it has certain anti-vibration and anti-shock capabilities, meeting the environmental standards of industrial-grade equipment.

- Physical Characteristics: The module size is 177.8mm×101.6mm×114.3mm (height × width × depth), weighs about 1kg, and adopts a standard DIN rail mounting method, which is convenient for installation and integration in the control cabinet, compatible with other modules of the same series, and saves installation space.

III. Functional Features

- Stable Processing Capacity: The 32-bit processor provides moderate computing speed, which can efficiently handle basic control tasks such as logical operations, timers, and counters. It also supports simple floating-point operations, meeting the control needs of small and medium-sized systems, ensuring that control instructions are executed quickly and reducing system response delays.

- Flexible Programming Support: It supports multiple programming languages of the IEC 61131-3 standard, including Ladder Diagram (LAD), Function Block Diagram (FBD), Structured Text (ST), etc. Engineers can choose the appropriate programming method according to project requirements and their own habits. The programming software is easy to operate, supporting online monitoring and program modification, improving development efficiency.

- Reliable System Guarantee: Adopting industrial-grade design, the internal circuit has undergone strict testing, with good anti-interference ability, and can run stably in industrial environments with electromagnetic interference. Equipped with a complete self-diagnostic function, it can monitor the power status, memory usage and communication status of the module in real time. When an abnormality occurs, it will prompt through the fault indicator, facilitating quick location of problems.

- Convenient Communication Function: Through the built-in RS-232 and DH+ interfaces, it can communicate with programming equipment, HMI (Human-Machine Interface) and other control equipment. It supports mainstream communication protocols such as Modbus, and can exchange data with sensors, actuators and other equipment, facilitating the construction of small industrial control networks and realizing centralized monitoring and data acquisition.

- Moderate Expansion Capacity: It supports the expansion of local I/O modules, and can increase digital and analog modules according to actual control needs to expand the input and output capabilities of the system. At the same time, it can connect remote I/O stations through the DH+ network, adapting to the expansion of the control system in scale and meeting the demand changes of different projects.

IV. Configuration and Programming Guide

- Development Environment: It is recommended to use GE Fanuc Proficy Machine Edition programming software. This software supports Windows operating systems, provides an intuitive programming interface and rich debugging tools, facilitating engineers to write, test and download programs.

- Typical Configuration Example:

- Configuration Steps: First, create a new project in the programming software and select the IC693CPU350-BC model; then configure the processor parameters, including memory allocation, communication port settings, etc.; then add the required I/O modules and communication modules, and define I/O addresses; after that, write the control program and perform syntax checking; finally, download the program to the CPU module and debug the program through the online monitoring function.

V. Fault Diagnosis and Maintenance

- Common Faults and Handling Methods:

- CPU fails to start: It may be due to poor power connection, exhausted battery power or damaged program. Solutions: Check the backplane bus power connection to ensure that the 5V DC power supply is normal; replace the backup battery; re-download the user program.

- Abnormal I/O communication: It is manifested as being unable to read or control the I/O module, which may be due to the module not being plugged in tightly, address conflict or module failure. Solutions: Re-plug the I/O module, check whether the module address setting is unique; replace the suspected faulty module for testing.

- No response from communication port: It may be due to wrong port settings, cable failure or port damage. Solutions: Check whether the communication parameters (such as baud rate, parity) match; replace the communication cable; if the port is damaged, the CPU module needs to be repaired or replaced.

- Program execution error: It may be due to program logic errors or insufficient memory. Solutions: Use the debugging function of the programming software to find and correct logic errors; optimize the program, delete redundant code, and free up memory space.

- Daily Maintenance: Regularly check whether the module is installed firmly and clean the dust on the surface of the module; check the status of the backup battery to ensure that the data backup function is normal; regularly back up user programs and system configurations to prevent data loss; when the system is shut down, check whether the connections of each interface are loose.