Description

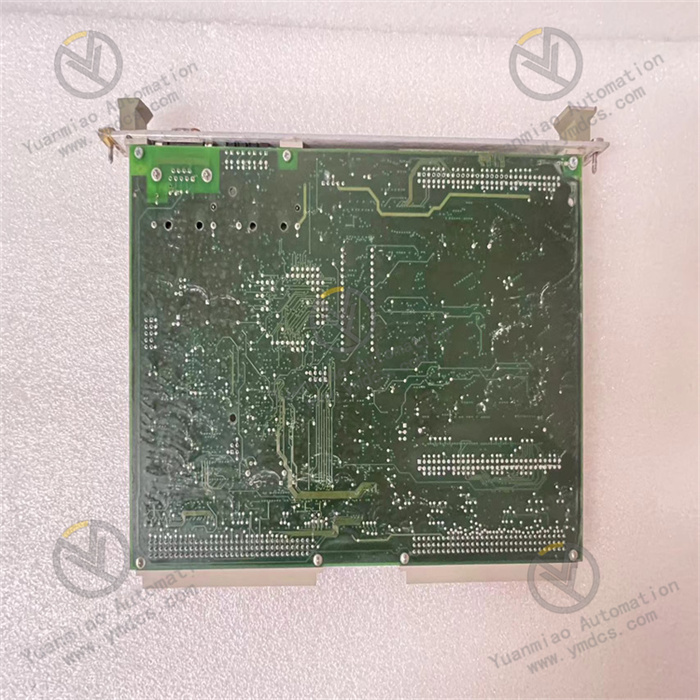

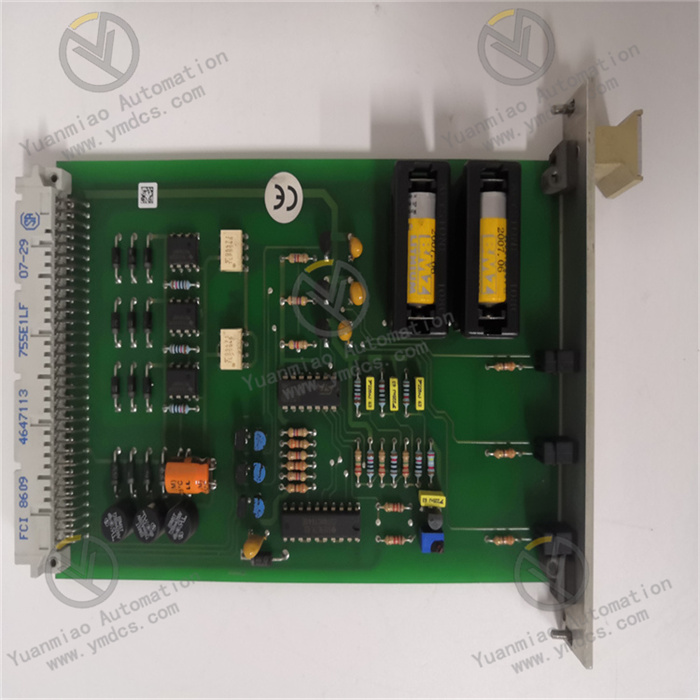

GE WESDAC D20ME

Overview

GE WESDAC D20ME is a high-performance modular controller based on the GE Multilin D20/D200 platform, belonging to the GE WESDAC series product system. It occupies a key position in industrial automation and control systems, mainly undertaking core tasks such as data processing, equipment control, and data interaction with other systems.

With advanced microprocessor technology and optimized digital signal processing algorithms, this controller can efficiently cope with complex industrial control scenarios. Whether it is real-time monitoring of industrial equipment or precise regulation of production processes, it can complete stably and excellently, providing strong support for the efficient and reliable operation of industrial production.

Technical Parameters

- Power Parameters: Supports wide voltage input, with AC input range of 110V - 380V AC and DC input range of 20V - 60V DC; rated power is 100W, which can adapt to the power supply environment of different industrial sites.

- Processor Specifications: Adopts a 32-bit FreeScale 68030 microprocessor with an operating frequency of 40MHz, featuring strong data processing capability and efficient handling of complex control tasks.

- Memory Configuration: Equipped with 16MB SDRAM as user memory for fast reading and writing of data; 2MB Flash memory (512KB of which is battery-backed) for storing important programs and data to ensure data is not lost in case of power failure; and 2MB SRAM for auxiliary operation.

- Communication Protocols: Supports multiple standard industrial communication protocols such as Modbus, Profibus, Ethernet, IEC 61850, and DNP 3, enabling seamless integration and data exchange with various industrial automation equipment and control systems.

- Physical Dimensions: Approximately 300mm x 200mm x 100mm (length × width × height), with an aluminum alloy housing and IP65 protection rating, having good dustproof and waterproof performance, and being able to adapt to harsh industrial environments; supports panel mounting or DIN rail mounting, which is convenient and flexible.

- Resolution and Sampling Rate: The resolution reaches 20 bits, enabling precise processing of various signals; the maximum sampling rate is 100kSPS, which can quickly capture signal changes, meeting industrial application scenarios with high real-time requirements.

- Input/Output Channels: Supports rich analog input/output and digital input/output channels. For example, the common configuration includes 8 analog inputs for monitoring analog signals, 16 digital inputs for collecting switching signals, and 8 digital outputs for controlling various equipment, which can meet the access needs of different industrial equipment and systems.

- Control Accuracy: The control accuracy can reach ±0.1%, ensuring precise control of industrial processes.

- Real-Time Clock Characteristics: The real-time clock has a resolution of 1 millisecond and an accuracy of ±2.0 ppm, providing an accurate time reference for time-sensitive industrial applications.

Functional Features

- High-Performance Processing Capability: With high-speed microprocessors and advanced digital signal processing algorithms, it can quickly and accurately process large amounts of data, meeting the high requirements for complex data processing and control in industrial automation applications, and ensuring the efficient operation of industrial production processes.

- Multi-Channel Flexible Control: Supports multiple types of input and output channels, and can monitor and control multiple devices or industrial processes at the same time, applicable to various complex industrial automation and control system scenarios, effectively improving the integration and control efficiency of the system.

- Rich Communication Interfaces: Equipped with multiple communication interfaces such as RS-232, RS-485, and Ethernet, and supports multiple communication protocols, which greatly facilitates integration with other industrial automation equipment and upper computer systems, enabling convenient data exchange and remote control.

- Real-Time Operation Response: It can perform data processing and control operations in real-time or near-real-time, meeting the strict real-time requirements of industrial automation applications, and can timely respond to changes in industrial sites, ensuring the stability and safety of production processes.

- High-Reliability Design: Adopting high-performance circuit design and high-quality materials, it has excellent anti-interference ability, can effectively resist the impact of harsh environmental factors such as electromagnetic interference, vibration, and impact in industrial sites, ensuring the continuous and stable operation of industrial processes, and reducing equipment failures and downtime.

- Intelligent Diagnosis and Safety Functions: It has perfect intelligent diagnosis functions such as sensor disconnection and short-circuit detection. When the system is abnormal, it can send an alarm signal in time and upload it to the control system through the communication interface; at the same time, it usually has safety functions, which can monitor abnormal signals or out-of-range situations and take corresponding measures to ensure the safe and stable operation of the system.

- Flexible Programming and Expandability: Supports multiple programming languages, such as ladder logic, function block diagram, structured text, etc., facilitating engineers to customize and develop programs according to actual needs; the modular architecture design allows flexible expansion of the number of communication interfaces, I/O channels, etc. by adding additional modules to meet the changing needs of industrial control systems without large-scale reconstruction of the system architecture.

Application Fields

- Industrial Automation Production Lines: In automated production lines such as automobile manufacturing and electronic equipment production, it is used to control the operation of robots, conveyors, machine tools and other equipment, realizing automated control and monitoring of production processes, ensuring the collaborative work of various equipment, and improving production efficiency and product quality. For example, precisely controlling the movement of robots on the automobile assembly line to ensure the accurate installation of parts.

- Power Systems: It serves as the core controller in substations, undertaking the important task of monitoring and controlling power equipment. For example, real-time monitoring of the operating status of transformers, circuit breakers and other equipment, and through accurate measurement and analysis of parameters such as current and voltage, realizing stable control of the power system and ensuring reliable power supply; at the same time, in power plants, it can be used to control the operation of generator sets and optimize power generation efficiency.

- Process Control Industry: It is widely used in industries with high process control requirements such as chemical industry, food and beverage, and pharmaceutical industry. For example, in chemical production, it accurately monitors and controls parameters such as temperature, pressure, and flow of reaction kettles to ensure that chemical reactions proceed according to set conditions, improving product quality and production safety; in food and beverage production, it controls links such as filling, sterilization, and packaging on the production line to ensure that products meet quality standards.

- Mechanical Equipment Control: It can be used to control various mechanical equipment, from small CNC machine tools to large industrial presses. Through real-time monitoring and adjustment of equipment operating parameters, it realizes efficient and stable operation of equipment and prolongs the service life of equipment. For example, in the processing process of CNC machine tools, it precisely controls the movement trajectory and cutting parameters of the tool.