Description

Kollmorgen CB06551 PRD-B040SSIB-63

The Kollmorgen CB06551 PRD-B040SSIB-63 is a high-performance servo drive commonly used in industrial automation, with wide applications in industries such as packaging machinery, textile machinery, printing equipment, robotics, steel plants, power plants, cement, chemical, paper manufacturing, and CNC machine tools.

Features

- High-Precision Control: Utilizes advanced control algorithms and technologies to achieve precise position, speed, and torque control, ensuring motors operate exactly as commanded. Suitable for equipment requiring high motion control accuracy, such as precision machine tools and electronics manufacturing equipment.

- Fast Dynamic Response: Exhibits rapid dynamic response capabilities, quickly tracking command signals and adjusting motor operation to enhance system dynamics. This enables devices to respond swiftly during rapid start/stop and speed changes, reducing delays and errors—performing excellently in scenarios like rapid robotic movements or high-speed packaging machinery operations.

- High Integration: Integrates multiple functions (e.g., power supply, controller, and motor drive), reducing system complexity and costs. This simplifies the design and setup of industrial automation systems, lowers hardware procurement and installation costs, and minimizes potential failure points.

- Strong Customizability: Can be customized for specific applications, such as adjusting control parameters or setting motion modes, to adapt to different motors and control system requirements, meeting various special industrial scenarios and personalized needs.

- High Reliability: Constructed with high-quality components and materials, and subjected to strict quality control and testing, ensuring high reliability and stability for long-term operation. Suitable for industrial environments requiring continuous operation, reducing maintenance and downtime while improving productivity.

- Easy Maintenance and Debugging: Provides a user-friendly human-machine interface and diagnostic functions, facilitating maintenance and debugging, reducing usage complexity and maintenance costs, and enabling even non-professionals to operate and troubleshoot easily.

- Good Environmental Adaptability: Capable of operating in diverse temperature and humidity conditions, with strong environmental adaptability to stabilize performance in harsh industrial environments, such as high-temperature metallurgical workshops or humid textile factories.

Technical Parameters

- Input Characteristics

- Input Voltage: Supports 115V or 230V AC input, adapting to different power systems.

- Input Phases: Supports single-phase or three-phase input, with 1.8/2.8kVA (input, single-phase/three-phase) and 1.4/2.2kVA (output).

- Control and Communication

- Communication Interfaces: Supports common industrial Ethernet fieldbuses such as EtherCAT, Ethernet/IP, Profinet, and SynqNet, enabling easy communication and control with upper-level computers, PLCs, and other devices.

- Built-in Functions: Includes integrated safety technologies to ensure safer machine operation.

- Output Capability

- Power Range: Continuous power output typically ranges from 300W to 50,000W, suitable for driving servo motors of different power classes.

- Peak Current: Capable of operating at peak current (usually 3 times the rated continuous current) for 5 seconds in some scenarios, enhancing the servo drive’s dynamic response performance.

- Mechanical and Environmental

- Dimensions: Approximately 120mm×90mm×25mm, with a compact design for easy installation in various devices.

- Weight: Approximately 0.3kg, lightweight to avoid excessive load on installation points.

- Other Parameters

- Operating Temperature: Approximately 36°C, ensuring normal operation within this range.

- Insulation Resistance: 350Ω, ensuring electrical insulation and safety for equipment and personnel.

- Load Impedance: 320Ω, matching external loads to maintain stable signal transmission and power output.

Working Principle

A servo system typically consists of a servo drive, servo motor, and encoder, operating on the principle of closed-loop control with the following core logic:

- Servo Drive (Controller/Driver)

- Signal Processing: Parses position, speed, or torque commands from upper-level systems (e.g., pulse signals, analog signals, communication protocol signals).

- Power Amplification: Converts DC power to three-phase AC via an inverter (e.g., IGBT module) to drive the servo motor.

- Closed-Loop Control: Compares actual motor position and speed feedback from the encoder with command values, forming a closed-loop PID control to ensure high-precision operation.

- Protection Functions: Features overcurrent, overvoltage, overheating, and overload protection to safeguard system safety.

- Function: Receives commands from upper-level systems (e.g., PLC, motion controllers), drives the servo motor, and adjusts motor status in real time via feedback signals.

- Working Principle:

- Servo Motor

- Permanent Magnet Synchronous Motor (PMSM): A common type used by Kollmorgen, where the rotor uses permanent magnets, and the stator winding generates a rotating magnetic field to drive synchronous rotation of the rotor.

- Asynchronous Motor (ACIM): Used in some scenarios, relying on the interaction between the stator magnetic field and rotor induction current for rotation.

- Integrated Feedback: Built-in encoders (incremental or absolute) provide real-time feedback on motor status to the drive.

- Function: Converts electrical energy into mechanical energy for precise position and speed control.

- Working Principle:

- Encoder

- Incremental Encoder: Generates pulse signals via a grating disk and photosensitive elements to calculate displacement and speed.

- Absolute Encoder: Directly outputs absolute motor position via encoded disk signals (e.g., binary codes), eliminating the need for homing.

- Function: Detects motor position, speed, and direction, providing feedback signals to the drive.

- Working Principle:

Application Cases

- Packaging Machinery: Used in automated packaging lines to control material conveying, item positioning, and packaging actions. For example, in carton packaging machines, this drive precisely controls servo motors to form cartons accurately, fill items correctly, and coordinate sealing actions, ensuring consistent packaging quality and production efficiency. In pharmaceutical packaging lines, it drives conveyor belts via servo motors to transport drugs at equal intervals and position them accurately, coordinating with packaging machines for cartoning and labeling—its high-precision control ensures packaging accuracy and aesthetics.

- Textile Machinery: Controls moving parts in textile production. In knitting machines, it precisely regulates needle movements to create different patterns and stitches, adjusting needle position and speed in real time via fast dynamic response to meet diverse knitting requirements and improve fabric quality and efficiency. In spinning machines, the drive controls rollers and spindles to precisely adjust drafting and winding tension, ensuring uniform yarn thickness and tight winding, enhancing spinning quality.

- Printing Equipment: Drives print head movement and paper conveying in digital printers. High-precision position control enables print heads to eject ink accurately on paper, achieving high-quality image and text printing. Fast dynamic response ensures precise coordination between print heads and paper at varying speeds, improving printing efficiency and accuracy. In large-format printers, it controls print head movement in two directions for high-precision graphic and text rendering, adjusting motion speed and acceleration rapidly for different tasks to boost productivity.

- Robotics: Controls robotic joint movements in industrial robots. In welding robots, it precisely regulates arm trajectories to position welding torches accurately and weld at optimal speeds and angles, ensuring stable welding quality. Its fast dynamic response allows robots to adjust motion states swiftly across different welding tasks and environments, enhancing efficiency. In handling robots, the drive controls joint movements for accurate item picking, transporting, and placing. High-precision position and torque control enable robots to handle items of varying weights and shapes and complete tasks quickly and accurately in complex environments.

Other Brand-Related Products

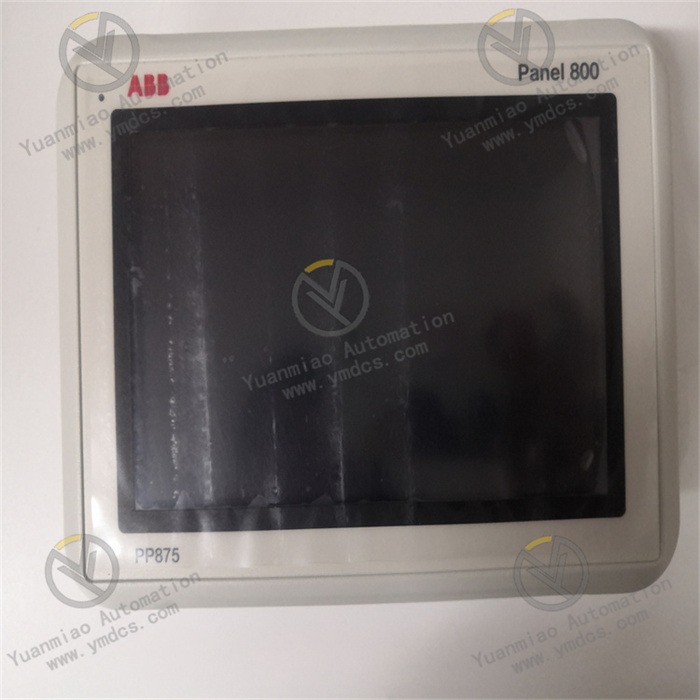

ABB PP826 3BSE042244R1 Operation Panel

ABB 500TRM02 1MRB150011R1 Coupler Module

GE UCSC H1 IS420UCSCH1A-B Controller Module

Bently 1900/65-00-01-03-01-01 Dual-Channel Vibration Monitor

Eaton CS-TX3-3. 81X2.54-64TW Terminal Acquisition Board