Description

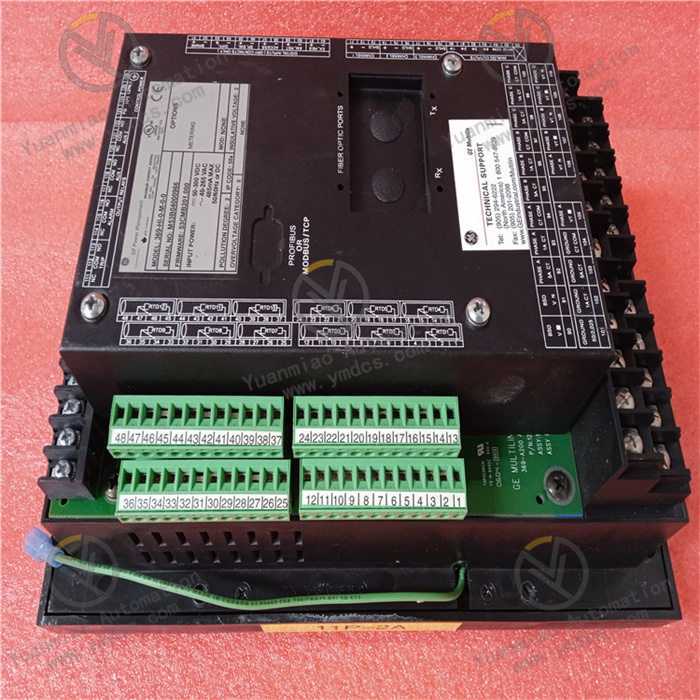

GE Multilin 369-HI-0-M-0-0

Overview

GE Multilin 369 - HI - 0 - M - 0 - 0 is a microprocessor - based motor management relay, belonging to the GE Multilin series of products. It is elaborately designed for the comprehensive protection and efficient management of medium - voltage motors. With its advanced technical architecture and rich functional modules, this relay occupies an important position in motor control scenarios in the industrial field. It can effectively deal with various faults that may occur during the operation of the motor, ensure the stable and reliable operation of the motor, and provide a solid guarantee for the continuity of the production process.

Technical Parameters

- Power Supply Parameters: The control power supply has wide adaptability, supporting a voltage input range of 50 - 300 VDC or 60 - 265 VAC, with a frequency range of 50/60 Hz. It can be easily connected to various common AC and DC power supply systems in industry, and is not afraid of complex and changeable power supply environments.

- Parameters Related to Protection Functions:

- Current Protection: It has the function of current imbalance detection, which can sensitively detect the unbalanced state of the three - phase current of the motor; it also has the ability to detect single - phase faults; it has a protection mechanism for ground faults, effectively avoiding potential safety hazards caused by abnormal grounding; it supports dual - speed motor protection to meet the operation needs of the motor under different working conditions; multiple phase overload curves are set, which can be flexibly adapted according to the actual operation characteristics of the motor.

- Other Protections: It can monitor and protect over - voltage and under - voltage conditions during the operation of the motor in real time; for the risk of motor overheating, it has a perfect overheating protection strategy; it can accurately detect the locked - rotor fault of the motor to prevent the motor from being damaged due to locked - rotor.

- Communication Interface Parameters: It is equipped with non - isolated RS232 and RS485 ports. The baud rate range of the RS232 port is 4800 to 19200, and it supports the Modbus RTU communication protocol, which facilitates data interaction with various upper computers, SCADA systems, PLCs and other equipment, and realizes the rapid transmission of remote monitoring and control commands.

- Measurement and Metering Parameters: A metering kit can be optionally equipped. When enabled, it can realize the phase voltage (VT/PT) input function, with a maximum VT ratio of 240:1, and supports VTs with open delta or star connection. This metering option additionally provides three field - programmable analog outputs. Together with the standard analog current output of the basic unit, all outputs share the same common loop, which can be used to monitor key operating parameters of the motor such as current, voltage and power in real time.

- Time Parameters: The time delay of the 87 differential switch is less than 200 ms, which can quickly respond when a fault occurs, cut off the circuit in time, and protect the safety of the motor and related equipment.

- Environmental Parameters: The operating temperature range is - 40℃ to + 60℃, the storage temperature range is - 40℃ to + 80℃, the allowable relative humidity range is 5% - 95% (non - condensing), and the protection level reaches IP50x. It can adapt to relatively harsh industrial environments and ensure stable operation under different temperature and humidity conditions.

- Physical Specification Parameters: The overall size is approximately 29.6 cm in height x 10.7 cm in width x 20.5 cm in length. It supports DIN rail mounting, which is simple and fast, and can effectively save the installation space in the control cabinet.

Functional Features

- Comprehensive Motor Protection Function: It integrates multiple protection functions such as over - current, under - current, over - voltage, under - voltage, current imbalance, single - phase, ground fault, overheating and locked - rotor, covering all possible fault types during the operation of the motor. It provides 360 - degree all - round safety protection for the motor, greatly reducing the risk of the motor being damaged due to faults.

- Flexible Configuration and Adaptive Ability: Users can flexibly adjust key parameters such as motor inrush current, cooling rate and acceleration according to the actual operation status and application scenarios of the motor, so that the protection characteristics of the relay can perfectly match the motor characteristics, realizing personalized and precise protection and management. In addition, the relay also has a certain "learning" ability, which can automatically adapt to the individual motion parameters of the motor and optimize the protection and control effect of the motor in specific application scenarios.

- Real - time Monitoring and Diagnosis Function: It can monitor the operating parameters of the motor such as current, voltage, temperature and vibration in real time, and conduct in - depth analysis of these data through built - in algorithms to predict potential faults of the motor in advance and send out early warning information in time. At the same time, it can monitor the entire start - up process of the motor to ensure a smooth start - up of the motor and avoid damage to the motor caused by abnormal conditions during the start - up process.

- Convenient Communication and Remote Management: With the help of communication interfaces such as RS232 and RS485 and communication protocols such as Modbus RTU, it can easily communicate with upper computers, SCADA systems, PLCs and HMI (human - machine interface) equipment. Through these communication links, staff can remotely monitor the motor in real time, adjust parameters and perform control operations, which greatly improves the convenience and efficiency of motor management.

- Event Recording and Waveform Capture: It has an event recording function, which can record in detail various key events during the operation of the motor, such as power faults, alarm information, self - test results, suppression actions and trip events, providing detailed data basis for fault diagnosis and equipment maintenance. At the same time, it supports the waveform capture function, which can record the electrical waveform at the moment when the motor fault occurs, helping technicians to deeply analyze the cause of the fault and formulate targeted solutions.

Application Fields

- Industrial Production and Manufacturing: In large industrial production enterprises such as steel, chemical, papermaking and textile industries, it is widely used in the protection and management of motors that drive various large mechanical equipment, such as rolling mill motors, reactor stirring motors, papermaking machine motors and textile machine motors. It ensures the stable operation of production equipment, avoids production stagnation caused by motor faults, and guarantees the normal production order of enterprises.

- Power Industry: In power facilities such as power plants and substations, it is used for the protection and control of auxiliary motors, fan motors, water pump motors and other equipment. It maintains the stability of the power production and transmission process, ensures the reliable operation of the power system, and provides a solid guarantee for the stable supply of electricity.

- Building Facilities Field: In large buildings such as commercial complexes, office buildings and hotels, it can be used for the management and protection of equipment such as compressor motors of air conditioning systems, ventilation fan motors and water pump motors of water supply and drainage systems. It ensures the normal operation of various electromechanical equipment in the building and provides a comfortable and convenient environment for users.

- Transportation Industry: In transportation hubs such as ports, docks and railways, it is used for the protection and control of crane motors, conveyor belt motors, loading and unloading equipment motors, etc. It improves the efficiency and safety of transportation operations and ensures the smooth progress of cargo loading, unloading and transportation processes.