Description

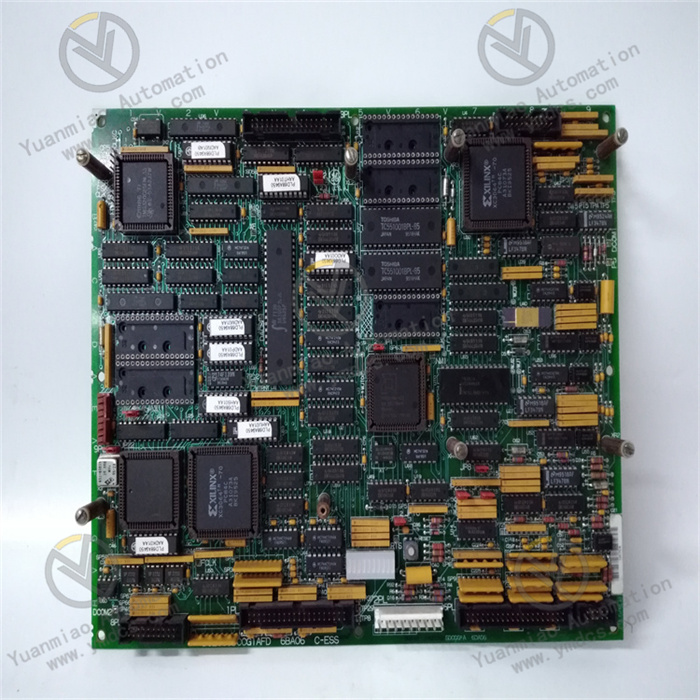

GE DS200SDCCG1AFD

I. Overview

The GE DS200SDCCG1AFD is a high-performance drive control board meticulously developed by General Electric (GE), playing a critical role in the field of industrial automation and control systems. It belongs to GE's classic DS200 series, which has gained wide acclaim in complex and changeable industrial environments for its excellent design and reliable quality. Inheriting the series' advantages, the DS200SDCCG1AFD demonstrates strong functionality and adaptability.

This control board constructs its core processing architecture based on the advanced TI C6713 DSP chip, featuring powerful computing capabilities to efficiently handle complex control algorithms and real-time processing of massive data, providing a solid guarantee for precise control of industrial equipment. In motor control scenarios, whether for AC induction motors, DC motors, or servo motors requiring extremely high control precision, the DS200SDCCG1AFD can achieve precise regulation of key parameters such as motor speed and torque with its outstanding performance, ensuring stable and efficient equipment operation.

As an important member of the Mark V series gas turbine control system, the DS200SDCCG1AFD undertakes the critical task of controlling the fuel flow of gas turbines. By precisely adjusting fuel input, it realizes accurate control of gas turbine speed and power, thereby ensuring stable power supply of the entire power generation system and playing an irreplaceable role in the power industry. In the field of industrial automation, it is widely applied in various production lines such as metallurgy, chemical industry, and textiles, connecting and controlling various actuators and sensors, coordinating the collaborative work of different devices, and promoting the automated and intelligent development of production processes.

II. Technical Parameters

1. Power Parameters

- Input Voltage: It shows wide compatibility. The basic input voltage is 24V DC, and some models can adapt to a broader range of AC 380 - 480VAC, meeting the access requirements of different industrial standard power supplies worldwide. This effectively reduces adaptation challenges caused by power differences, ensuring the equipment can stably obtain electrical energy in various power supply environments.

- Output Voltage: The output voltage varies according to application scenarios and load types. Common output ranges are 24V DC or up to 600V DC, capable of providing appropriate drive voltages for various actuators, motors, and power semiconductor devices to meet the diverse requirements of different devices for voltage amplitude.

- Power Consumption: While ensuring high-performance operation, energy consumption is strictly controlled. The typical power consumption is approximately 20W, conforming to the development trend of modern industry for energy conservation and efficiency improvement, helping enterprises reduce long-term operating costs.

2. Electrical Parameters

- Microprocessor Configuration: The board is equipped with three microprocessors. The Motor Control Processor (MCP) uses an 80C196 microcontroller, featuring rich functions such as high-speed I/O, traditional digital I/O, analog I/O, timers/counters, and watchdog timers. Collaborating with the high-performance processor based on the TI C6713 DSP chip, it enables parallel processing of complex control algorithms, greatly improving system response speed and control accuracy.

- Channel Count and Interfaces: It has 16 digital input/output channels, enabling simultaneous connection of multiple sensors, actuators, and other devices to realize signal interaction and collaborative control among multiple devices in complex industrial systems. Meanwhile, it is equipped with various standard communication interfaces such as RS232, CAN, and Ethernet, supporting communication protocols like Modbus RTU and TCP/IP, facilitating data interaction with other devices and control systems, and easily integrating into various complex industrial automation networks.

- Frequency Response and Control Accuracy: The frequency response range covers 20Hz to 20kHz, capable of precisely processing various signals within this frequency band. Whether low-frequency slow-varying signals or high-frequency fast pulse signals, they can be accurately captured and processed. The speed control accuracy reaches ±0.1%, and the torque control accuracy reaches ±5%, providing strong support for the stable and precise operation of motors and other equipment.

3. Mechanical and Environmental Parameters

- Operating Temperature Range: The operating temperature range is extremely wide, reaching -40°C to 70°C, and some materials show it can even withstand extreme temperatures from -40°C to 85°C. This excellent temperature adaptability makes it immune to various extreme climatic conditions and complex industrial environment temperature changes worldwide. Whether in cold polar industrial facilities or scorching desert factories, it can operate stably to ensure the continuity of industrial production.

- Humidity Range: It can work reliably in an environment with a relative humidity of 5% to 95% (non-condensing), demonstrating good humidity tolerance, effectively avoiding the risk of circuit failures caused by humidity changes, and ensuring normal operation in scenarios such as humid coastal area factories or industrial production workshops with large humidity fluctuations.

- Protection Level: The protection level is IP65, with excellent dust-proof and water-proof capabilities, which can effectively block external factors such as dust and water splashes from eroding the internal precision circuits, providing comprehensive protection for the internal circuits and significantly extending equipment service life.

- Dimensions and Weight: In terms of dimensions, some models are 100mm x 70mm x 25mm. The compact shape design gives it significant advantages when installing in industrial control cabinets and equipment interiors with limited space, facilitating flexible layout. Other models have dimensions of 200mm x 150mm x 50mm, weighing about 1kg. The moderate weight is convenient for handling and installation operations, and it will not cause excessive burden on the installation structure during equipment operation.

III. Functional Features

1. Powerful Computing Capability Brought by High-Performance Processor

The high-performance processor based on the TI C6713 DSP chip endows the DS200SDCCG1AFD with powerful computing capabilities, enabling it to quickly and accurately process complex control algorithms and a large amount of real-time data. In the control scenario of industrial robots, facing the massive data generated by the collaborative movement of multiple robot joints and the demand for complex trajectory planning, this control board can complete calculations in an extremely short time, real-time adjust motor control parameters, ensure smooth and precise robot movements, and greatly improve production efficiency and product quality.

2. Integration of Rich Control Functions

The control board integrates various advanced control functions, such as vector control and V/F control, allowing flexible selection of control strategies according to different motor types and application scenarios. In the control of AC induction motors, vector control technology can decompose the motor current into excitation current and torque current, realizing decoupling control of motor speed and torque, so that the motor can maintain efficient operation under different working conditions, effectively improving energy utilization.

3. Advantages of Modular Design

Adopting a modular design concept, each functional module of the DS200SDCCG1AFD is relatively independent, facilitating quick location and replacement of faulty modules during maintenance, greatly shortening downtime and reducing maintenance costs. At the same time, users can flexibly increase, decrease, or replace modules according to different industrial scenario requirements, optimize and upgrade the system to adapt to diversified and complex control tasks. For example, during production line upgrading and transformation, access and control of new equipment can be realized by adding specific functional modules without large-scale replacement of the entire control system.

4. Real-Time Monitoring and Diagnosis Functions

It has real-time monitoring functions, which can real-time monitor key parameters during equipment operation, such as temperature, pressure, flow rate, motor current, voltage, etc. Once parameter abnormalities occur, the built-in diagnostic system can quickly capture them and display fault codes in BCD or binary form through 10 diagnostic LEDs. Different fault levels correspond to different flashing modes, facilitating maintenance personnel to quickly locate the cause of the fault. For example, faults 1 - 399 flash at a slower speed, and faults 400 - 1023 flash at a faster speed. This intuitive fault indication method greatly improves the efficiency of fault troubleshooting and ensures the stable operation of the system.

5. Good Compatibility and Expandability

The DS200SDCCG1AFD has good compatibility with GE's Mark V series control systems and can seamlessly integrate into the control system architecture of this series to work collaboratively with other devices. Meanwhile, it has strong expandability, supporting external SD cards and USB devices for data storage and transmission expansion. The number of I/O points can be expanded to a maximum of 256, and more external devices can be connected through expansion interfaces to meet the continuous upgrading and expansion needs of industrial automation systems. When building new or upgrading industrial automation production lines, it can easily adapt to the changes in system scale expansion and function increase, reserving sufficient space for the future development of enterprises.