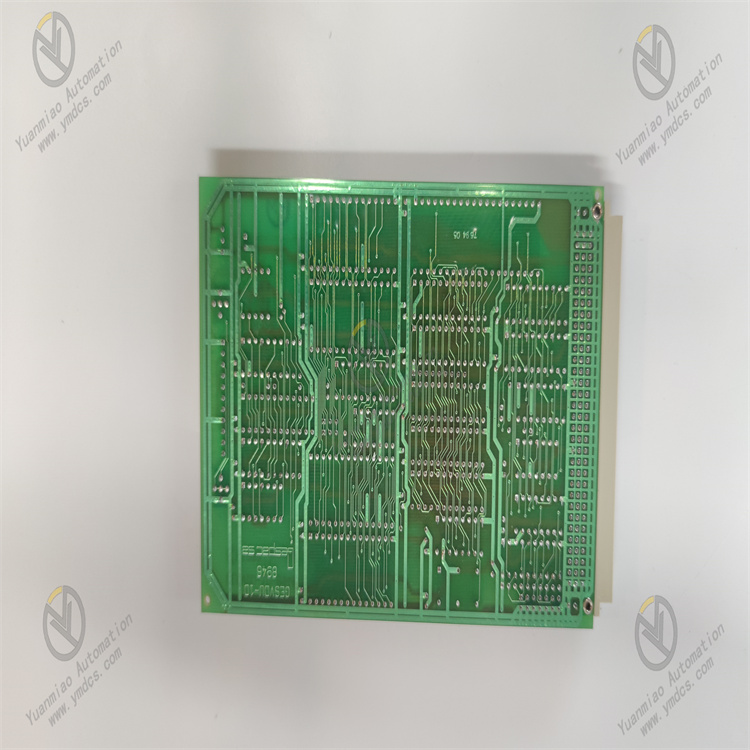

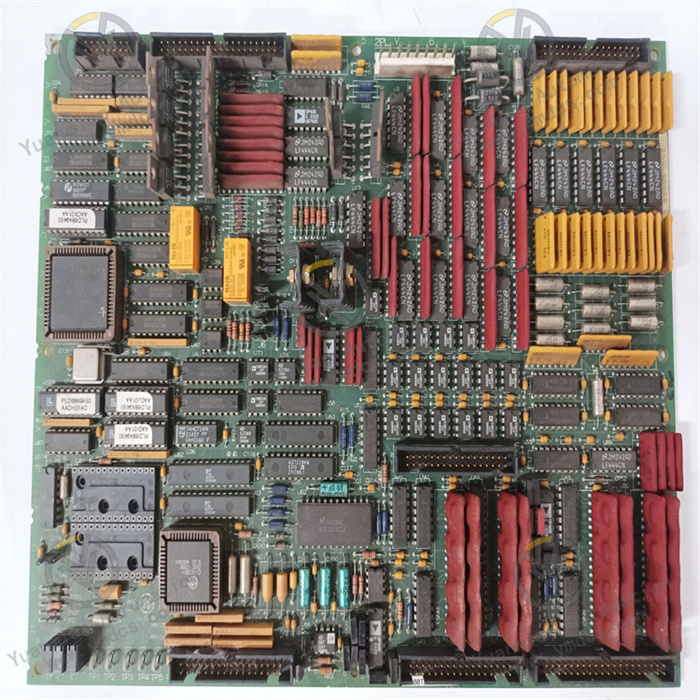

Description

GESVDU-1D-8946

The GESVDU-1D-8946 is a signal processing and drive control module, with its core positioning to achieve integrated control of sensor signal acquisition, logical operation, and actuator driving. Relying on its high integration, stable driving performance, and flexible adaptability, it is widely used in scenarios such as machine tool servo control, production line transmission systems, and start-stop control of small and medium-sized chemical equipment, providing core support for the precise operation of industrial equipment.

1. Technical Parameters

Signal Acquisition Parameters: Supports 8 channels of analog input (4-20mA/0-10V) with an accuracy of ±0.1% FS; 4 channels of digital input (DC24V) with a response time of ≤10μs; the isolation voltage between input channels is ≥500V AC, effectively preventing interference.

Drive Output Parameters: 2 channels of analog output (4-20mA) with an accuracy of ±0.2% FS; 4 channels of digital output (DC24V/10A), supporting relay/transistor output switching; equipped with overcurrent and overvoltage protection, and the protection threshold can be configured via software.

- Core Processing and Communication: 32-bit RISC processor with a main frequency of 300MHz, supporting basic logical operations and PID regulation; standard RS485 (Modbus-RTU) and Ethernet (TCP/IP) interfaces, with a communication delay of ≤5ms.

- Environmental and Physical Parameters: Operating temperature ranges from -10℃ to 60℃, and storage temperature ranges from -40℃ to 85℃; relative humidity is 5%-95% (no condensation); electromagnetic interference resistance complies with the IEC 61000-4-2/3 standard; dimensions are 150mm×120mm×80mm, with DIN rail mounting, compatible with standard industrial control cabinets.

2. Functional Features

- Integrated Acquisition and Control, Simplifying System Architecture: It integrates analog/digital acquisition and drive output functions, eliminating the need for additional signal conversion modules. This reduces system wiring and equipment footprint, lowers integration costs, and is particularly suitable for the compact design needs of small and medium-sized equipment.

Precise Driving and Multiple Protection: The digital output supports high-current driving, which can directly control actuators such as small and medium-sized motors and solenoid valves; built-in overcurrent, overvoltage, and short-circuit protection mechanisms cut off the output within 0.1ms in case of faults, protecting the safety of the module and actuators.

- Integration of Basic Control Algorithms: It has built-in standard PID and logical interlock algorithms, supporting manual/automatic control switching. It can directly realize closed-loop regulation of parameters such as temperature and pressure without relying on upper computers, simplifying the control process.

- Comprehensive Diagnosis and Convenient Operation and Maintenance: It real-time monitors input and output signals, power supply status, and module temperature. In case of faults, fault codes (e.g., "E01" represents an overcurrent fault) are uploaded through LED indicators and communication interfaces; it supports real-time monitoring of module status via upper computer software, facilitating remote troubleshooting.

3. Working Principle

Signal Acquisition: Sensors (such as pressure transmitters and photoelectric switches) transmit on-site signals to input channels. The analog input module converts signals such as 4-20mA into digital signals, and the digital input module receives equipment status signals, which are then transmitted to the processor after filtering.

- Logical Operation: The processor calls the preset program and performs logical judgment or PID calculation based on the collected signals. For example, in motor speed control, it compares the actual speed with the set value and calculates the drive signal parameters through the PID algorithm.

- Drive Output: The output module converts the control signals calculated by the processor into signals recognizable by the actuator, driving the operation of motors, control valves, etc.; at the same time, it real-time monitors the output status and feeds it back to the processor to form a closed loop.

4. Common Faults and Solutions

- Fault 1: No Input Signal Display

- Causes: Sensor failure, loose wiring, damaged input channel.

- Solutions: Use a multimeter to detect the sensor output signal; re-tighten the wiring and polish the terminals; replace the sensor with a spare channel to check for channel faults.

- Fault 2: No Output Drive, with Overcurrent Fault Alarm

- Causes: Actuator short circuit, output channel overload, excessively low protection threshold setting.

- Solutions: Disconnect the actuator and measure the resistance to check for short circuits; replace with a high-power actuator; adjust the protection threshold to a reasonable range via software.

- Fault 3: Communication Interruption

- Causes: Damaged communication cable, mismatched parameters, damaged interface.

- Solutions: Replace the cable and check the wiring; verify parameters such as IP address and baud rate; test with a spare interface to check for interface faults.

- Fault 4: Large Fluctuations in PID Control Parameters

- Causes: Unreasonable parameter tuning, interference in sensor signals.

- Solutions: Optimize PID parameters through the self-tuning function; replace with shielded cables and ground them to reduce interference.