Description

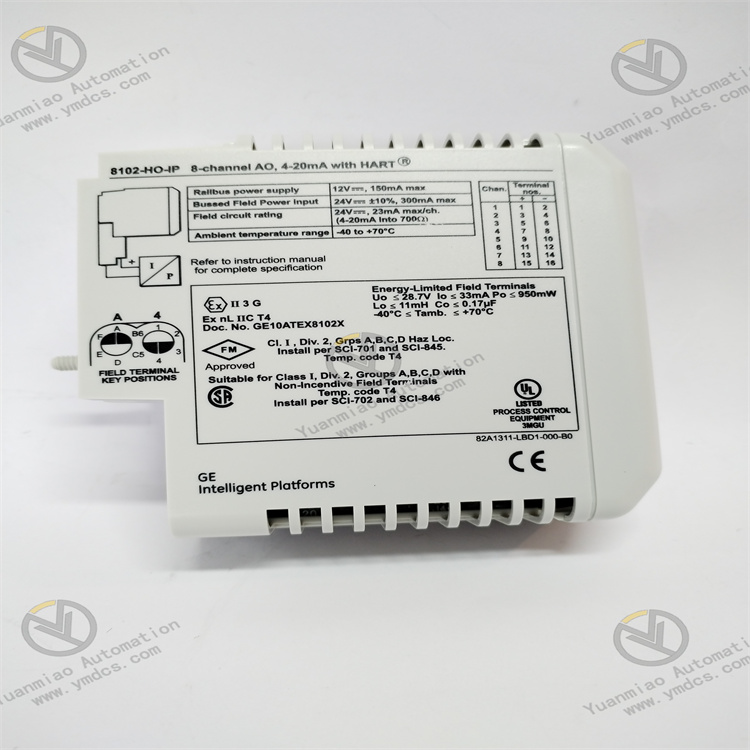

GE 8102-HO-IP

The GE 8102-HO-IP is an Ethernet communication module, whose core positioning is to solve the problem of high-speed data transmission between industrial equipment and control systems. Relying on stable communication performance, wide protocol compatibility and strict environmental adaptability, it is widely used in data interaction scenarios among Distributed Control Systems (DCS), Programmable Logic Controllers (PLC) and upper computers (such as SCADA, HMI) in fields like electric power, chemical industry, intelligent manufacturing and metallurgy. It serves as an important bridge connecting underlying equipment and upper monitoring systems.

Communication Performance: Supports 10/100Mbps adaptive Ethernet speed and adopts full-duplex communication mode, with a communication delay of ≤5ms. A single module supports a maximum of 64 concurrent communication connections and mainstream network protocols including TCP, UDP, IP and Modbus-TCP, with a protocol conversion response time of ≤1ms.

- Interface Parameters: Equipped with 2 RJ45 Ethernet interfaces (supporting automatic crossover/straight-through switching) and 1 RS485 auxiliary debugging interface. The Ethernet interfaces support Auto-MDI/MDI-X automatic negotiation, with a transmission distance of ≤100m (using Cat5e twisted-pair cables).

Power Supply and Power Consumption: Supports wide-voltage input of DC24V±10% and has overcurrent, overvoltage and reverse connection protection functions. The rated power consumption is ≤5W, and the no-load standby power consumption is ≤1W, featuring excellent energy efficiency.

- Environmental Adaptability: Operating temperature ranges from -20℃ to 70℃, and storage temperature ranges from -40℃ to 85℃. The relative humidity is 5%-95% (no condensation). It meets the IEC 61000-4-2/3/4 standard for electromagnetic interference resistance, with an IP20 protection rating (for the module itself), making it suitable for complex industrial on-site environments.

- Physical Parameters: Dimensions are 100mm×80mm×30mm. It adopts standard DIN rail mounting and weighs ≤150g, allowing flexible integration into various control cabinets.

The GE 8102-HO-IP has distinct differentiated features with "high-speed stability, wide compatibility, convenience and reliability" as its core advantages:

High-Speed and Low-Latency Communication for Real-Time Interaction: It uses a dedicated communication processing chip and optimizes the data transmission link. At a speed of 100Mbps, it can realize fast transmission of massive data and complete the command response between equipment and the upper computer within 5ms, which is far better than the 10ms delay of ordinary communication modules. It is suitable for scenarios with high timeliness requirements such as power dispatching and real-time process control.

- Multi-Protocol Compatibility for Cross-System Interconnection: In addition to supporting basic Ethernet protocols, it natively supports the mainstream Modbus-TCP industrial protocol. It can expand support for protocols like PROFINET and EtherNet/IP through firmware updates, easily realizing interconnection and intercommunication between equipment of different brands (such as GE, Siemens, Rockwell) and monitoring systems, and solving the "protocol island" problem in traditional industrial scenarios.

Dual Fault-Tolerance Design for Improved Operational Reliability: It supports redundant connection of dual Ethernet interfaces. When the main interface fails, it automatically switches to the backup interface with a switching time of ≤100ms. It has a built-in data verification mechanism, which ensures no packet loss or wrong code in data transmission through CRC32 verification, achieving a communication success rate of 99.99% in complex electromagnetic environments.

Convenient Configuration and Diagnosis for Reduced O&M Costs: It supports visual configuration through a web page. No professional programming software is required, and parameters such as IP address and protocol type can be set via a browser. It has a built-in self-diagnosis function that monitors the communication link and power supply status in real time. When a fault occurs, it provides accurate prompts through LED indicators (power light, communication light, fault light), and can quickly locate problems with the help of the RS485 debugging interface.

- Industrial-Grade Protection for Severe Scenarios: It uses wide-temperature industrial-grade components and has passed high-low temperature cycle and vibration impact tests. It has an integrated surge protection circuit that can resist ±2kV instantaneous surges, enabling stable operation in industrial on-site environments with power grid fluctuations, high temperature and high humidity.

The core working process of the GE 8102-HO-IP is "data reception - protocol conversion - transmission feedback", with a clear workflow:

Data Reception: Underlying equipment (such as PLC, sensors) transmits data to the module via RS485 or internal bus. The signal receiving unit of the module filters and amplifies the data to remove noise caused by electromagnetic interference and converts it into a standard digital signal.

Protocol Conversion: The dedicated communication chip reads the received data, converts the data format according to the preset protocol type (such as Modbus-TCP), transforms the private data format of the underlying equipment into IP data packets transmittable via Ethernet, and adds a check code to ensure data integrity.

- Transmission and Feedback: The converted IP data packets are transmitted to the upper computer (such as SCADA) through the Ethernet interface. The control commands issued by the upper computer after processing are transmitted back to the underlying equipment through the same reverse process. The module monitors the transmission status in real time. If packet loss occurs, it automatically retransmits, with the number of retransmissions ≤3, ensuring that the commands are executed properly.

Fault 1: The power indicator is not on, and the module does not work.

Fault 2: The communication indicator flashes, and data transmission is interrupted.

Fault 3: There is packet loss in data transmission, and verification fails.

Fault 4: Failed redundant switching of dual interfaces.

- Causes: Faulty backup interface, incorrect redundant configuration.

- Solutions: Replace the network cable of the backup interface for testing; if it is ineffective, the module interface is faulty and needs to be replaced; enter the web page to check the redundant switching conditions and interface priority configuration, save again and restart the module.

![]()