Description

GE IS420PUAAH1A

The GE IS420PUAAH1A is a high-performance power supply module designed for industrial-grade distributed control systems. As a core power supply component of the GE Fanuc RX3i series Programmable Logic Controllers (PLCs), it is positioned as a "dedicated redundant power supply terminal for medium-to-large industrial control scenarios". Its core function is to provide stable and reliable DC power supply for RX3i series PLC systems and external industrial equipment. By integrating dual-channel redundant power supply units, high-precision voltage regulation modules, and real-time status monitoring circuits, it achieves accurate output of power supply voltage, dynamic load distribution, and rapid fault response. Meanwhile, it features overcurrent, overvoltage, overtemperature, and short-circuit protection functions, providing core power supply guarantee for the stable operation of control systems in medium-to-large industrial production processes such as electric power, metallurgy, petrochemicals, and rail transit.

With high power supply precision, flexible redundant configuration, strong environmental adaptability, and comprehensive protection mechanisms, this module is well-adapted to industrial scenarios requiring multi-equipment collaboration, continuous production, and high reliability. It serves as a key power supply unit for the GE Fanuc RX3i series PLC systems to achieve "stable power supply - precise regulation - safe operation".

Its application scenarios accurately match the power supply needs of medium-to-large industrial control:

- In the electric power field, as the core power supply module of the DCS control system in thermal power plants, it is deployed in the PLC control cabinet of the central control room. It provides stable DC power for RX3i PLC hosts, distributed I/O modules (e.g., IC695I/O series), and on-site monitoring instruments, with a power supply precision of ±0.5%, ensuring that the collection of key parameters such as furnace pressure and flue gas oxygen content, as well as the transmission of control commands, are not affected by voltage fluctuations.

- In the metallurgical field, it is used in the PLC control system of cold rolling production lines in steel plants. Through the dual-channel redundant power supply design, it supplies power to the rolling mill speed control module, tension sensor, and hydraulic actuator. When one power supply channel fails, the other switches seamlessly within 5ms, ensuring that the thickness accuracy of cold-rolled steel strips is controlled within ±0.01mm.

- In the petrochemical field, it is adapted to the Safety Instrumented System (SIS) of large-scale refining and chemical plants. While withstanding high-temperature, high-humidity, and corrosive gas environments, it provides intrinsically safe power supply for key safety equipment such as emergency shutdown valve control modules and toxic gas detection instruments, and supports power supply compatibility with third-party safety instruments to ensure the safe and continuous operation of refining and chemical processes.

As a dedicated power supply module of the RX3i series, it supports seamless adaptation with in-series CPU modules (e.g., IC695CPU315), communication modules (e.g., IC695ETM001), and HMI (Human-Machine Interface). Through the GE Proficy Machine Edition configuration software, it realizes real-time monitoring of power supply parameters and fault early warning, meeting the strict power supply requirements of "high stability, high reliability, and high safety" for industrial control.

In terms of hardware architecture and system compatibility, the IS420PUAAH1A adopts a hardware architecture of "dual-channel redundant power supply unit + high-precision voltage regulation module + status monitoring and protection circuit". Its core consists of dual-channel industrial-grade switching power supply units, high-precision voltage sampling circuits, redundant control chips, fault diagnosis modules, and output interfaces.

The module is equipped with 2 independent input interfaces (supporting wide-range input of AC 220V or DC 24V) and 4 DC output interfaces. The output voltage can be configured as DC 5V, 12V, or 24V via DIP switches, with a maximum single-channel output current of 20A and a total output power of 400W, allowing flexible distribution of power supply circuits according to load requirements. It has a built-in high-precision PWM (Pulse Width Modulation) voltage regulation chip, which cooperates with a voltage feedback regulation circuit to achieve precise control of the output voltage, with a voltage ripple of ≤50mV, ensuring the stable operation of sensitive electronic equipment.

In terms of redundancy design, the module supports two modes: hot-swap redundancy and parallel redundancy. It realizes the synchronous operation of dual or multiple modules through a redundant control bus. When the main power supply module fails, the standby module switches automatically within 5ms, with an output voltage fluctuation of ≤0.1V during the switching process, ensuring the continuous operation of load equipment. It supports parallel operation of up to 4 modules to achieve flexible expansion of power supply capacity, with a maximum total output current of 80A.

In terms of protection performance, it adopts a dual protection mechanism of "multiple hardware protection + software monitoring". At the hardware level, it integrates overcurrent protection (configurable protection threshold), overvoltage protection (triggered when the output voltage exceeds 15% of the rated value), overtemperature protection (triggered when the module temperature exceeds 85℃), and short-circuit protection (automatically cuts off the output when the instantaneous short-circuit current is ≤100A). At the software level, it monitors the output voltage, current, and module temperature in real time through configuration software, and immediately sends an alarm signal and executes protection actions when parameters exceed the threshold.

Relying on the industrial-grade reinforced design, the module uses wide-temperature-tolerant components (-25℃~75℃), corrosion-resistant output terminals, and an enhanced heat dissipation structure (aluminum heat sink + intelligent fan cooling). It complies with the IEC 60068-2 series of environmental adaptability standards and can operate stably in industrial sites with high temperature, high humidity, and strong electromagnetic interference.

The IS420PUAAH1A adopts a dual-channel independent power supply unit design, supporting wide-range input of AC 100V~240V or DC 110V~300V. The input method can be flexibly selected according to on-site power supply conditions, and the two input channels can be connected to different power supply circuits respectively to achieve redundant backup on the input side.

The module supports two core redundancy modes: hot-swap redundancy and parallel redundancy. In the 1+1 redundant configuration, the two modules operate synchronously: the primary module undertakes the main load power supply, while the standby module monitors the operating status of the primary module in real time. When the primary module experiences faults such as abnormal input voltage, output overcurrent, or module overtemperature, the standby module automatically switches to the main power supply mode within 5ms. During the switching process, the output voltage fluctuation is ≤0.1V, and there is no power failure or restart of the load equipment, ensuring the continuous operation of the control system.

In the N+1 parallel redundant configuration, up to 4 modules can be operated in parallel. The redundant control chip realizes dynamic balanced distribution of the load, with a load current deviation of ≤5% among each module. When one of the modules fails, the remaining modules automatically share the load of the faulty module, maintaining stable total output power. A maximum continuous output current of 80A can be achieved, adapting to the high-load power supply needs of large-scale PLC systems. For example, in the rail transit signal control system, a 2+1 redundant configuration with 3 parallel modules is adopted, providing a total output current of 60A to power the signal processing unit, track circuit monitoring module, and switch control equipment. Even if one module fails, the remaining two modules can still meet the full-load power supply demand, ensuring the stable transmission of train operation signals.

The module is equipped with a built-in high-precision PWM voltage regulation chip and a voltage feedback regulation circuit, adopting a closed-loop control mechanism of "sampling - comparison - regulation" to achieve precise control of the output voltage. Under the rated load (20A), the output voltage precision reaches ±0.5%, which is much higher than the conventional precision requirement (±1%) of industrial-grade power supplies.

To meet the power supply needs of different load equipment, the output voltage can be quickly configured as DC 5V, 12V, or 24V via the DIP switches on the front of the module, and can also be remotely fine-tuned via configuration software (adjustment range ±5%), adapting to the power supply needs of different types of equipment such as CPUs, sensors, and actuators.

It has a built-in low-ripple filter circuit, which adopts a multi-stage LC filter topology to effectively filter out high-frequency noise and voltage fluctuations. The peak-to-peak output voltage ripple is ≤50mV, providing clean power supply for sensitive electronic equipment such as PLC analog acquisition modules and high-precision sensors, and avoiding data acquisition errors caused by voltage ripples. For example, in the power supply scenario of chromatographic analysis instruments in the chemical industry, the module outputs DC 24V to power the detection unit of the instrument, with the voltage ripple controlled within 30mV, which improves the detection precision of the instrument for mixed gas components by 10% and reduces the detection error to ≤0.01%.

In addition, the module has load adaptability. When the load current dynamically changes within the range of 0~20A, the output voltage fluctuation is ≤0.2V, ensuring stable power supply under working conditions such as equipment start-stop and load mutation, and avoiding equipment misoperation caused by voltage fluctuations.

The module adopts a dual protection mechanism of "hardware fast protection + software delayed protection", covering multiple fault scenarios such as overcurrent, overvoltage, overtemperature, short-circuit, and undervoltage, and comprehensively ensuring the safety of the power supply module and load equipment.

At the hardware protection level, it integrates components such as fast fuses, overvoltage suppression diodes, and temperature relays. In case of a short-circuit fault, the fuse blows within 10μs to cut off the power supply circuit; when the output voltage exceeds 15% of the rated value, the overvoltage suppression diode turns on instantly to clamp the voltage within a safe range; when the internal temperature of the module exceeds 85℃, the temperature relay automatically cuts off the input power to prevent the module from being burned.

At the software protection level, the built-in microcontroller collects real-time data on output current, voltage, and module temperature at a sampling frequency of 1kHz. When parameters exceed the set threshold, an alarm signal is sent first; if the fault persists for 100ms without being resolved, protection actions (such as current limiting, power-off, or switching to the standby module) are executed to avoid system shutdown caused by false triggering of protection.

The module has a fault memory function, which can store the latest 100 fault records, including fault type, occurrence time, and voltage/current parameters at the time of the fault. Fault records can be read via configuration software, facilitating maintenance personnel to trace the cause of faults. For example, in the rolling mill control scenario in the metallurgical industry, when the load current exceeds 25A instantaneously due to the start of the rolling mill motor, the module first triggers current limiting protection to limit the output current to 22A, and at the same time sends an overcurrent alarm signal to the PLC. If the current does not drop within 100ms, it switches to the standby module for power supply, which not only protects the power supply module but also avoids the interruption of rolling mill control.

The module adopts a triple anti-interference design of "electromagnetic shielding + signal isolation + power supply filtering", enabling stable operation in high-interference industrial environments.

In terms of electromagnetic shielding, the module housing is made of high-strength galvanized steel sheet, and a 0.4mm-thick copper foil shielding layer is laid on key internal circuits (such as voltage regulation chips and control circuits). The housing and shielding layer form a complete electromagnetic shielding system through multi-point grounding, with a shielding effectiveness of ≥70dB, complying with the IEC 61000-4-3 standard for radio frequency radiation immunity (20V/m), which can effectively resist strong electromagnetic radiation interference generated by equipment such as frequency converters and high-voltage motors.

In terms of signal isolation, photoelectric isolation technology is used between the input circuit and the output circuit, with an isolation voltage of ≥3kVrms; magnetic isolation technology is used between the control circuit and the power circuit, with an isolation voltage of ≥2kVrms. This effectively blocks ground loop interference and common-mode interference, and avoids the impact of on-site high-voltage signals on the power supply control circuit.

In terms of power supply filtering, the input side is equipped with an EMC (Electromagnetic Compatibility) filter, which can filter out 50/60Hz fundamental interference and high-frequency harmonics in the power grid; the output side adopts a multi-stage filter circuit to further suppress voltage ripples and noise.

In terms of environmental adaptability, the module uses wide-temperature-tolerant components (-25℃~75℃), with core chips selected from industrial-grade wide-temperature models. It is equipped with an intelligent heat dissipation system (aluminum heat sink + temperature-controlled fan): the fan starts automatically when the module temperature exceeds 50℃ and stops when the temperature is below 40℃, ensuring heat dissipation effect while reducing energy consumption. Its anti-vibration performance meets the 5g acceleration requirement of the IEC 60068-2-6 standard, allowing direct installation in control cabinets near vibration sources such as pumps and fans. With a protection level of IP20 and a dust-proof cover, it can effectively prevent dust intrusion and adapt to dusty industrial environments. If equipped with a custom protective enclosure, the protection level can be upgraded to IP65, adapting to harsh environments such as outdoors and high humidity.

The module has comprehensive status monitoring and convenient maintenance functions, realizing real-time mastery of the operating status through a dual method of "local indication + remote monitoring".

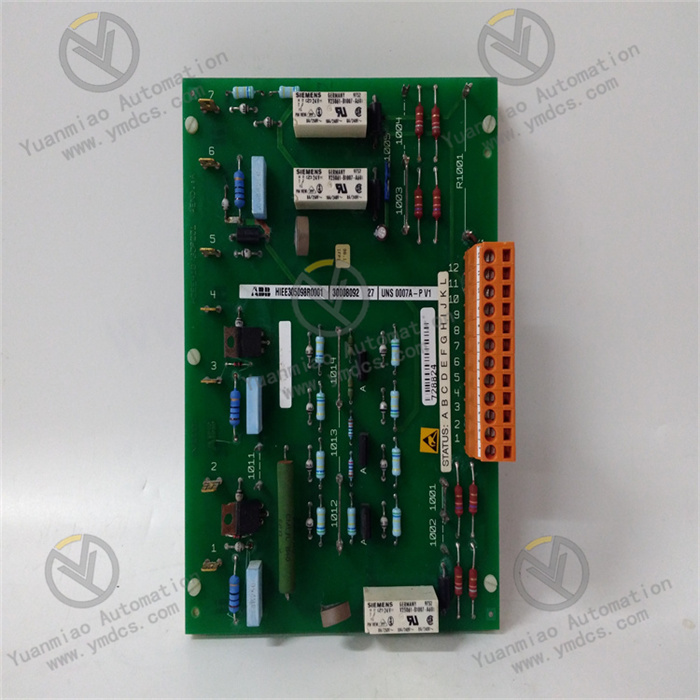

In terms of local status monitoring, the front of the module is equipped with an LED indicator group, including an input power indicator (steady green for normal input), an output status indicator (steady green for normal output, blinking for load overload), a redundancy status indicator (steady blue for normal redundancy, blinking red for redundant abnormality), and a fault indicator (steady red for module fault, blinking yellow for early warning). Maintenance personnel can quickly judge the basic operating status of the module through the indicators.

![]()