Description

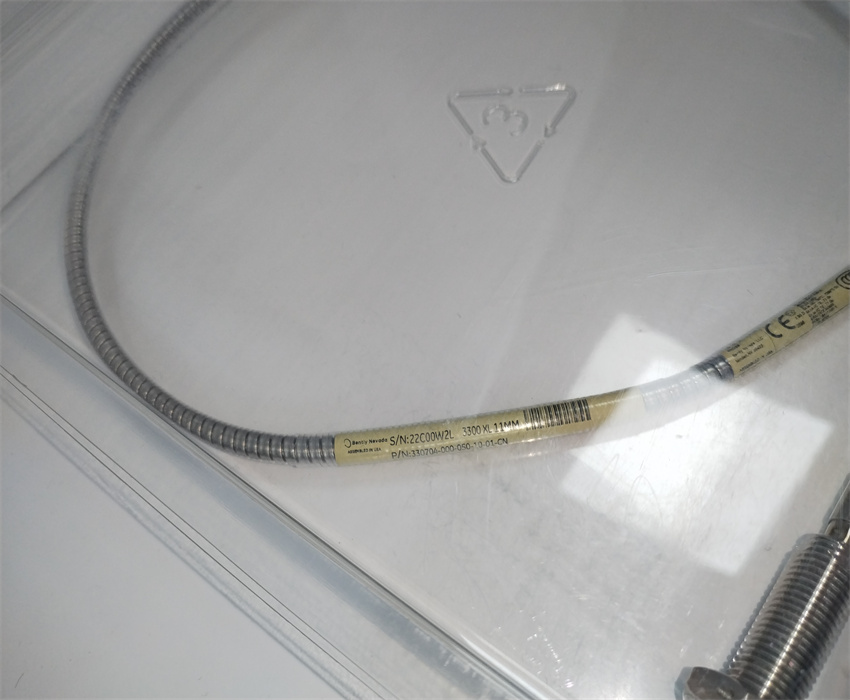

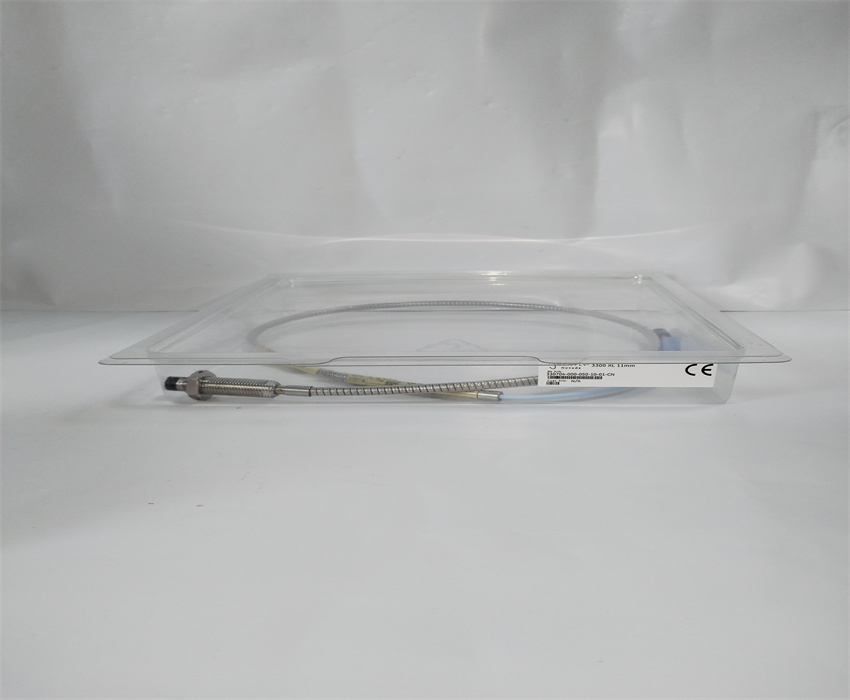

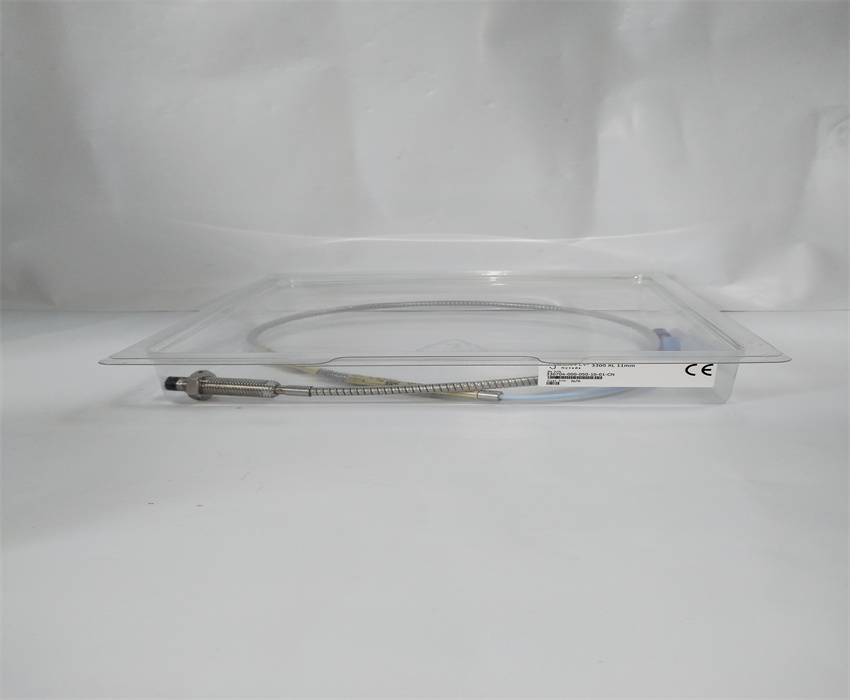

Technical Specifications Input and Output Characteristics: It is used in conjunction with the eddy current sensor probe to convert the distance change between the probe and the measured object detected by the probe into corresponding voltage signals for output. Generally, the output signal range is from -20V to -4V (corresponding to different probe measurement ranges), which can provide stable and accurate measurement signals for the subsequent monitoring system. Measurement Range: Combined with specific eddy current sensor probes, different measurement ranges can be achieved. For example, this model may correspond to a specific measurement range. Common measurement ranges include 0-2mm, 0-5mm, etc., to meet the measurement requirements of parameters such as displacement and vibration of different mechanical equipment. Operating Frequency: It has a relatively wide operating frequency response range, usually reaching around DC to 10kHz, which can effectively capture the vibration and displacement signals of different frequencies during the operation of mechanical equipment. Power Supply Requirements: Generally, it requires a DC power supply. The common supply voltage is 18V to 30V DC, and the power consumption is relatively low to ensure stable operation in an industrial environment. Temperature Range: The operating temperature range is generally between -40°C and +85°C, and the storage temperature range is usually between -40°C and +100°C, which can adapt to the relatively harsh temperature conditions of the industrial environment.

Features and Advantages High-precision Measurement: Based on the eddy current principle, it can achieve high-precision displacement and vibration measurement with high resolution. It can accurately detect the minute changes in the operating status of mechanical equipment, providing a reliable basis for equipment condition monitoring and fault diagnosis. Non-contact Measurement: Adopting a non-contact measurement method, it will not cause wear to the measured object. It is suitable for various rotating and reciprocating mechanical equipment, such as steam turbines, compressors, pumps, etc., and can perform measurements stably for a long time. Strong Anti-interference Ability: It has good anti-electromagnetic interference and anti-radio frequency interference capabilities. It can maintain the accuracy and stability of measurement in a complex industrial electromagnetic environment, ensuring the reliability of monitoring data. Easy Installation and Maintenance: With a compact structure, it is easy to install. It also has high reliability and requires little maintenance work. It has good compatibility with other monitoring systems and equipment of Bently Nevada, making it easy to integrate into the overall equipment condition monitoring solution. Application Areas Power Industry: It is used to monitor parameters such as shaft displacement, shaft vibration, and differential expansion of steam turbine generator sets, and to detect the abnormal operating status of equipment in a timely manner to ensure the safe and stable power production. Petroleum and Chemical Industry: It monitors the operating status of key equipment such as compressors and pumps. By measuring parameters such as the vibration and displacement of the equipment, it prevents the occurrence of equipment failures and avoids production losses caused by equipment shutdowns. Metallurgical Industry: During the steel production process, it can monitor the operating status of equipment such as rolling mills and fans to ensure the normal operation of the equipment and improve production efficiency and product quality. Mechanical Manufacturing: It is used for quality control in the research, development, testing, and production processes of mechanical equipment. By measuring the displacement and vibration of key components of the equipment, it optimizes the design and performance of the equipment.

Common Faults and Solutions

Abnormal Output Signal

Possible Causes: Sensor probe failure, damage to the connection cable between the preamplifier and the probe, internal circuit failure of the preamplifier, abnormal power supply, etc.

Solutions: Check whether the sensor probe is working properly. You can use a normal probe of the same model for replacement testing; Check whether the connection cable is damaged, open-circuited, or poorly connected. If there are any problems, repair or replace the cable in a timely manner; Measure whether the power supply of the preamplifier is within the specified range. If the power supply is abnormal, check the power supply system; If all of the above are normal, it may be an internal circuit failure of the preamplifier, and professional maintenance personnel need to be contacted for inspection or replacement.

Inaccurate Measurement

Possible Causes: Incorrect probe installation position, the gap between the probe and the measured object does not meet the requirements, incorrect parameter settings of the preamplifier, etc.

Solutions: Check whether the installation position of the probe meets the installation requirements to ensure the correct relative position between the probe and the measured object; Measure the gap between the probe and the measured object and adjust it to the specified gap value; Check the parameter settings of the preamplifier, such as gain, linear range, etc., to ensure the settings are correct.

Communication Fault (if there is a communication function)

Possible Causes: Poor connection of the communication cable, damage to the communication interface, incorrect setting of the communication protocol, etc.

Solutions: Check whether the connection of the communication cable is firm and whether there is any damage or poor connection; Check whether the communication interface is normal. If it is damaged, repair or replace it in a timely manner; Confirm whether the communication protocol settings are consistent with those of other devices, and make adjustments if there are any errors.