Description

GE IS200EPSMG1AED

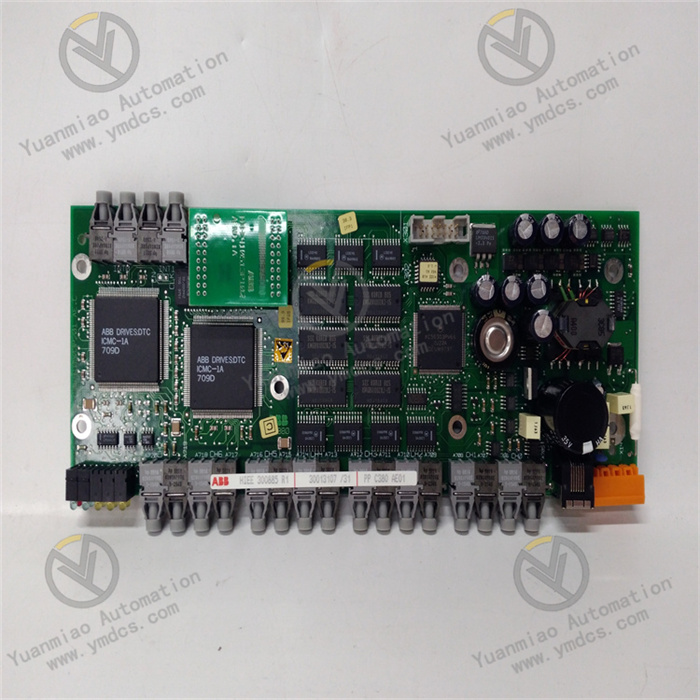

The GE IS200EPSMG1AED is a dedicated power conversion module for excitation control systems under General Electric (GE) Industrial Systems. Its core positioning is "excitation system hierarchical power supply hub - multi-component power adaptation unit - Mark series controller power interface". Its core function is to work in deep synergy with EPDM power modules in the excitation systems of gas/steam turbines in power generation, oil and gas, energy, and other fields. It accurately converts the input power into isolated voltage levels that meet the requirements of various components of the excitation system, providing stable and isolated power supply for the EX2100 excitation regulator, M1/M2/C controllers of the Mark VI/VIe system, and peripheral interface modules such as EDCD and EDEX. At the same time, through hardware-level fault monitoring and redundant power supply design, it ensures the power supply safety of the excitation system under complex working conditions, and is a "core power component" that guarantees the accuracy of excitation regulation and continuous operation of equipment.

As a key power supply module for the GE Speedtronic series excitation systems, this module has core advantages of "wide adaptability - high isolation - strong stability": it supports 24VDC main output and auxiliary voltage output, accurately matching the power supply needs of peripheral components with different power levels; it features dual electrical isolation between input and output as well as between output channels, with an isolation voltage of ≥500V AC, which completely blocks interference transmission; its industrial-grade hardware design can withstand a wide temperature range of -20°C to 55°C, high humidity, and vibration environments, and has obtained CE and UL certifications; it is deeply compatible with the Mark VI/VIe control system and compatible with new and old excitation components of the same series, allowing upgrading without large-scale system modification. It is widely used in scenarios such as generator excitation systems in thermal power plants, gas turbine control units, and excitation circuits of petrochemical compressor units, and is a key support for realizing "reliable excitation and undisturbed power supply" of industrial power equipment.

The core advantage of the IS200EPSMG1AED lies in its "24VDC + 70VDC dual isolated output" design, which completely resolves the pain points of "common power interference and signal drift between high/low voltage components" in excitation systems. In the EX2100 excitation system of a 600MW unit in a thermal power plant, the module converts the 125VDC provided by the EPDM into two isolated power supplies: 24VDC is supplied to the M1/M2/C redundant controllers and EDCD data acquisition modules (which collect excitation current and voltage signals with an accuracy requirement of ±0.1%), and 70VDC is supplied to the EXTB contact wetting modules and ECTB relay driving modules. The dual isolation design prevents the switching noise (≤100mVpp) of the 70VDC circuit from being transmitted to the 24VDC control circuit, increasing the signal-to-noise ratio of the signals collected by the EDCD module by 30%, optimizing the excitation regulation accuracy from ±0.5% to ±0.3%, and avoiding regulation fluctuations caused by traditional non-isolated power supplies.

The module adopts full industrial-grade hardware selection and low-temperature optimization design, enabling stable operation in environments with high/low temperatures and wide voltage fluctuations. In an outdoor gas turbine power station in northern China in winter (-20°C), the cold startup time of the module is ≤100ms, and the 24VDC output accuracy has no deviation (within ±0.24V) without the need for additional heating equipment. In coastal petrochemical plants (95% RH humidity), the PCB moisture-proof coating and sealed interfaces prevent salt spray and moisture from entering, allowing continuous operation for 6 years without circuit corrosion. In the face of workshop power fluctuations (18-24VDC), the wide-voltage auxiliary input design ensures stable output voltage, avoiding controller restart caused by sudden voltage drops. Compared with old modules of the same series, its environmental adaptation range is expanded by 20%, meeting the application needs of multiple regions and working conditions.

The linkage design between the module and the EPDM module, along with multiple protection mechanisms, significantly reduces the risk of power supply failures in the excitation system. In the Mark VIe system of a gas turbine combined cycle power plant, when the main EPDM power module fails, the IS200EPSMG1AED can switch to the backup input within 50ms after the backup EPDM module is powered on, ensuring no interruption of the 24VDC output and no shutdown of the M1/M2/C controllers. If the 24VDC output terminal is accidentally short-circuited, the 10A current limiting protection of the module is activated immediately to avoid overload damage to the EPDM module. At the same time, the "overcurrent fault" information is uploaded to the operation and maintenance platform via RS485, allowing maintenance personnel to locate the problem without on-site inspection, reducing the fault handling time to less than 15 minutes.

The module's compatibility with the Mark VI/VIe system and new/old peripheral components resolves the problem of "hardware mismatch and the need for overall replacement" during excitation system upgrades. In the renovation of the excitation system of an old thermal power plant, the original system used Mark VI controllers and EDCD1A modules. After adding the IS200EPSMG1AED, the old power modules (such as the old version of IS200EPSMG2ADC) can be directly replaced without replacing the controllers or peripheral components. Its RS485 communication interface can be directly connected to the original operation and maintenance network without additional configuration of communication protocols, reducing the integration time by 50% compared with traditional renovation solutions. The system shutdown time during renovation is controlled within 4 hours, significantly reducing production loss.

The module's high conversion efficiency and convenient monitoring design realize the dual value of "energy saving + cost reduction". In the excitation system of a compressor unit operating continuously for 24 hours in a petrochemical plant, a conversion efficiency of ≥92% reduces the annual power consumption of each module by 280kWh compared with similar products, saving more than 20,000 yuan in electricity costs per year for 10 units. The 4 TP test points allow maintenance personnel to directly measure the output voltage with a multimeter without disassembling the module or disconnecting the wiring, reducing the daily inspection time by 30%. At the same time, the module supports remote monitoring of output current and internal temperature, enabling early prediction of overload or overheating risks (e.g., early warning when the 24VDC current continuously exceeds 8A), avoiding sudden faults, and extending the module's service life to more than 8 years (the average service life of ordinary modules is 5 years).

- Power Supply Status Monitoring: Check the module's output parameters through the Mark VI/VIe operation and maintenance interface daily: the 24VDC voltage should be between 23.76V and 24.24V, the 70VDC voltage should be between 68.6V and 71.4V, and the output current should not continuously exceed the rated value (24VDC ≤8A, 70VDC ≤2A); check the communication status (normal RS485 connection, no packet loss) and fault alarms (no overcurrent, overvoltage, or overheating prompts).

- Physical and Interface Inspection: Check the module's installation screws weekly (torque 0.6-0.8N・m) to avoid loosening caused by vibration; clean the dust on the module surface and TP test points with a dry brush to prevent poor contact; check the EPDM module connection wires (125VDC input) and output terminals to ensure no oxidation of the terminals (oxidized contacts can be slightly polished with sandpaper).

- Test Point Calibration: Measure the output voltage through the TP test points with a high-precision multimeter (accuracy ±0.01V) monthly, and compare it with the data on the operation and maintenance interface; the deviation should be ≤±0.05V; test the continuity of the fuse (if blown, replace it with a 1A/250V fast-blow fuse of the same specification, and never use a larger capacity one as a replacement).

- Environment and Temperature Monitoring: Measure the module's surface temperature with an infrared thermometer quarterly (should be <50°C during normal operation); strengthen cabinet ventilation (air speed ≥1m/s) in high-temperature seasons (ambient temperature exceeding 40°C); check the humidity inside the cabinet (avoid condensation, and a dehumidifier can be installed) to prevent the PCB coating from failing due to moisture.

- Linkage Test: Trigger the EPDM main-standby switching test every six months, observe that the module's output switching time is ≤50ms and the controller does not restart; simulate the switching between 24VDC light load (1A) and heavy load (8A) to verify the output voltage stability (deviation ≤±0.2V).

![]()