Description

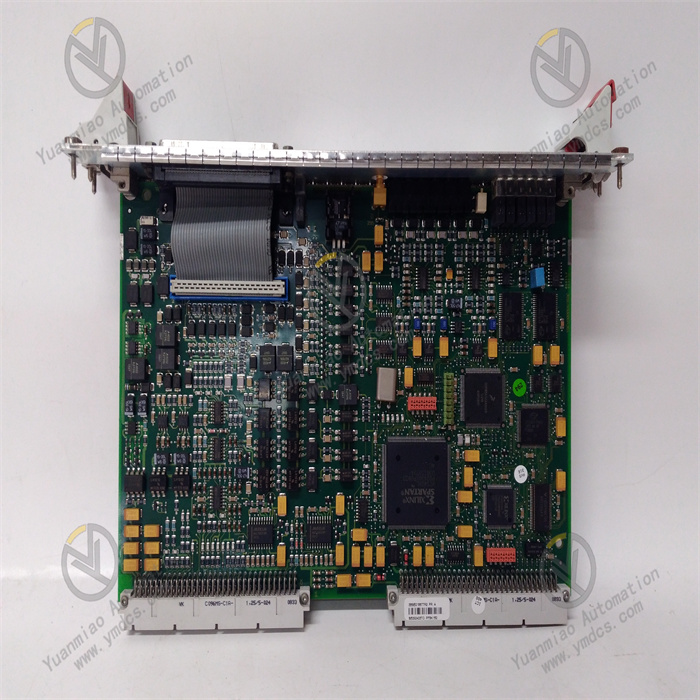

GE IS220PRTDH1BC

The GE IS220PRTDH1BC is an enhanced RTD (Resistance Temperature Detector) temperature acquisition module based on the GE Mark VIe control system architecture. It must be used in conjunction with Mark VIe controllers (e.g., IC698CPE030), reinforced racks (e.g., IC698CHS020), and IS220PPROH1A process control modules. Its core functions include:

- Collecting temperature signals via 16 differential RTD input channels, compatible with extended platinum resistance sensors such as PT100 (385Ω/℃), PT1000 (3850Ω/℃), and PT200 (770Ω/℃);

- Incorporating a built-in 24-bit high-precision Σ-Δ ADC converter to achieve accurate temperature conversion over an ultra-wide range of -250℃~850℃ (covering the liquid nitrogen temperature range);

- Featuring enhanced RTD fault diagnosis (open circuit/short circuit/drift) and intelligent lead resistance compensation (0~15Ω, supporting 5-wire connection);

- Supporting configuration of low-temperature startup parameters and filtering levels via the GE Mark VIe Configuration Tool;

- Transmitting temperature data to the process control module through a reinforced backplane bus, providing basic data for PID regulation in extreme scenarios.

Its core advantages lie in "ultra-wide temperature adaptability (-55℃~85℃), enhanced protection (IP65 + 316L stainless steel housing), extended RTD compatibility (PT200/PT1000), and high shock and vibration resistance (50g shock)". It is particularly suitable for extreme scenarios such as nuclear power low-temperature cooling systems (-196℃~50℃), outdoor monitoring at polar research stations (-55℃~20℃), and deep-sea detection equipment (-2℃~30℃, high water pressure).

The IS220PRTDH1BC collects the temperature of liquid nitrogen cooling pipelines (PT200 sensor, measurement range -196℃~50℃) via 16 RTD channels. The enhanced lead compensation function eliminates the resistance error of 200-meter low-temperature cables (compensation range 0~15Ω), maintaining the temperature acquisition accuracy at ±0.15℃. This provides accurate low-temperature data for the IS220PPROH1A process control module, ensuring no deviation in the PID regulation of the cooling system and avoiding overheating of nuclear island equipment (with a single failure loss exceeding RMB 200 million). In the outdoor environment monitoring of an Antarctic research station, the module withstands ultra-low temperatures of -55℃ and high humidity of 95%, collects atmospheric temperature (PT100 sensor, measurement range -55℃~20℃), and operates continuously for 180 days without low-temperature startup failures, with a Mean Time Between Failures (MTBF) of ≥1,500,000 hours, meeting the "unmanned operation and long-term operation" requirements in polar regions. In a 3,000-meter deep-sea detection equipment, the module, with IP65 protection and a 316L stainless steel housing, withstands 60MPa water pressure and high salt spray corrosion, collects the temperature of underwater sediments (PT1000 sensor, measurement range -2℃~30℃), and achieves stable data transmission without signal interruption caused by water pressure or corrosion.

In terms of hardware design, the module adopts an "extreme environment reinforcement + high-precision conversion" architecture:

- RTD Input and Protection Circuit: 16 differential RTD input channels, supporting 3-wire/4-wire/5-wire connections (5-wire for ultra-long-distance wiring compensation), and compatible with PT100/PT200/PT1000 platinum resistors. Each channel is equipped with a low-temperature constant current source (0.5mA/1mA optional, current stability ≤0.1%/℃ at low temperatures) to avoid the impact of RTD self-heating at low temperatures (self-heating error ≤0.02℃). It supports intelligent lead resistance compensation (0~15Ω, automatically identifying cable material and length), with a maximum wiring distance of 800 meters (AWG 20 low-temperature cable).

- High-Precision Low-Temperature Conversion Unit: Built-in 24-bit Σ-Δ ADC converter (low-temperature drift ≤3ppm/℃), with a configurable sampling rate (0.1Hz~100Hz) and a temperature measurement range of -250℃~850℃. The accuracy is ±0.1℃ (0℃~200℃), ±0.2℃ (-100℃~0℃/200℃~850℃), and ±0.3℃ (-250℃~-100℃). It is equipped with a low-temperature drift reference voltage source (drift ≤2ppm/℃ at -55℃~85℃) to ensure stable accuracy at low temperatures.

- Housing and Extreme Protection: Adopting a 316L stainless steel housing (salt spray corrosion resistance ≥5,000 hours), its dimensions comply with the 3U standard rack (19 inches), with an installation depth ≤250mm, compatible with Mark VIe reinforced racks. It has an IP65 protection rating (dust-proof, water-jet proof, no damage after 30 minutes at 10 meters underwater). A built-in heating film (automatically heating to -40℃ during low-temperature startup, power consumption ≤5W) ensures normal startup at ultra-low temperatures of -55℃.

- Safety and Diagnosis Design: It complies with the IEC 61508 SIL 2 safety certification, and key circuits (ADC, constant current source, heating film) adopt a triple-redundant design. It features RTD drift detection (alarm when deviation exceeds 0.5℃), channel overvoltage protection (±40V), and low-temperature startup fault diagnosis. Fault information is transmitted to the controller through the reinforced backplane bus and can be viewed in real time via software (e.g., "Channel 5 RTD Drift", "Low-Temperature Heating Film Fault").

With "low-temperature performance optimization" as its core, the IS220PRTDH1BC addresses the pain points of traditional RTD modules, such as "failure to start at ultra-low temperatures and accuracy attenuation":

- Ultra-Wide Temperature Coverage: The measurement range of -250℃~850℃ covers liquid nitrogen temperature (-196℃), polar low temperatures (-55℃), and industrial high temperatures (850℃). In nuclear power low-temperature cooling systems, it accurately collects the temperature of -196℃ liquid nitrogen pipelines with an accuracy of ±0.3℃, avoiding excessive cooling (which may crack pipelines) caused by low-temperature data distortion.

- Intelligent Low-Temperature Startup: The built-in heating film (automatically starting at -55℃, power consumption ≤5W) heats the internal temperature of the module to -40℃ within 10 minutes, ensuring the normal operation of the ADC and constant current source. In the -55℃ outdoor environment of the Antarctic research station, the module starts without failures and continuously collects atmospheric temperature.

- Stable Accuracy at Low Temperatures: The ADC has a low-temperature drift of ≤3ppm/℃, and the reference voltage source has a drift of ≤2ppm/℃ at -55℃~85℃. At a low temperature of -100℃, the temperature acquisition deviation is ≤0.2℃, far better than traditional modules (deviation ≥1℃ at -100℃). In deep-sea detection equipment, it ensures accurate water temperature acquisition in the range of -2℃~30℃.

Through hardware reinforcement design, the module withstands erosion from extreme environments:

- High Protection Rating: IP65 protection + 316L stainless steel housing provides salt spray corrosion resistance for ≥5,000 hours. In 3,000-meter deep-sea detection equipment, it withstands 60MPa water pressure and high salt spray, operating continuously for 1 year without housing corrosion or internal water ingress. In coastal nuclear power projects, it is not affected by seawater salt spray, extending the module's service life to 10 years.

- Strong Shock and Vibration Resistance: With 50g shock resistance and 10g vibration resistance, the module remains free from loosening and signal interruption in the bumpy environment of polar research vehicles. During the transportation of nuclear power equipment, it can still collect temperature normally without accuracy attenuation after withstanding 20g shock.

- Condensation Prevention Design: Equipped with a built-in humidity sensor and heating dehumidification function, it automatically heats and dehumidifies when the humidity exceeds 95% and the temperature is close to the dew point. In the high-humidity nuclear island cooling room, there is no condensation inside the module, avoiding circuit short circuits.

In response to the characteristics of "multiple sensor types and long wiring distances" in extreme scenarios, the module improves applicability through extended compatibility and intelligent compensation:

- Support for Multiple RTD Types: Compatibility with PT100/PT200/PT1000 allows adaptation to scenarios with different accuracy requirements without replacing the module (e.g., PT200 for high-precision low-temperature measurement in nuclear power, PT100 for regular measurement in research stations). In a comprehensive polar research project, one module collects both PT100 atmospheric temperature and PT200 equipment low temperature, reducing the number of modules by 50%.

- 5-Wire Intelligent Compensation: Supports 5-wire connection (2 wires for power supply, 2 wires for signals, 1 wire for compensation) with a compensation range of 0~15Ω and a maximum wiring distance of 800 meters. In the long-distance wiring (600 meters) between the nuclear island and control room of nuclear power plants, the lead resistance error is fully compensated, reducing the temperature acquisition deviation from 0.5℃ to 0.15℃.

- Cable Material Identification: Intelligently identifies cable materials (copper/silver) and automatically adjusts compensation coefficients to avoid compensation errors caused by different cable materials. In a project using silver low-temperature cables, the compensation accuracy is improved by 30% after automatic identification by the module.

Through full-dimensional diagnosis functions, the module solves the problems of "difficult maintenance and long fault troubleshooting time" in extreme scenarios:

- RTD Drift Detection: Real-time monitoring of RTD resistance drift (alarm when deviation exceeds 0.5℃) provides early warning of sensor aging. In nuclear power low-temperature systems, PT200 sensor drift is detected 3 months in advance, avoiding temperature misjudgment caused by delayed replacement.

- Low-Temperature Component Diagnosis: Monitors the working status of the heating film (e.g., "Heating Film Not Started", "Heating Timeout") and the current stability of the low-temperature constant current source. At the Antarctic research station, when the module detects a heating film fault, it immediately switches to the backup heating circuit without interruption of acquisition.

- Remote Status Monitoring: Supports transmission of module health data (temperature, humidity, heating film status) via a reinforced Ethernet (vibration-resistant), allowing maintenance personnel to check the status without reaching extreme sites. In deep-sea detection projects, remote monitoring of module operation via satellite communication reduces deep-sea maintenance costs.

![]()