Description

Functional Features

Input Signal Processing: It can receive various types of input signals, such as digital signals, analog signals, etc., and convert them into a format that the system can recognize and process, providing accurate information feedback for the control system.

Alarm Function: It has an undervoltage alarm function. When the input voltage is lower than the set value, it can promptly send out an alarm signal to remind the operator to take corresponding measures to avoid damage or malfunction of the equipment due to abnormal voltage. The alarm range can be set according to actual needs, including multiple options such as alarm, alarm and auxiliary 2, alarm and auxiliary 2 and auxiliary 3, alarm and subsidiary 3, auxiliary 2, auxiliary 2 and auxiliary 3, auxiliary 3, etc.

Relay Allocation: Alarm relays and trip relays can be allocated to perform corresponding control operations according to different fault conditions. For example, when an undervoltage fault occurs, the trip relay can be used to cut off the circuit to protect the safety of the equipment. Technical Parameters

Undervoltage Alarm Pickup: It is 0.85x the rated range, with a value range between 0.60 and 0.99x the rated value, and a step size of 0.01.

Startup U/V Alarm Pickup: It is also 0.85x the rated range, with the same value range and step size as the undervoltage alarm pickup.

Undervoltage Alarm Delay: The time is 3.0 seconds, which can be adjusted between 0.0 and 60.0 seconds, with a step size of 0.1 second.

Undervoltage Trip Sensor: The set value is 0.80x the rated range, with a value range between 0.60 and 0.99x the rated value, and a step size of 0.01.

Startup U/V Trip Sensor: It is 0.80x the rated range, with the same value range and step size as the undervoltage trip sensor.

Undervoltage Trip Delay: The time is 3.0 seconds, which can be adjusted between 0.0 and 60.0 seconds, with a step size of 0.1 second.

Application Fields

Industrial Automation Production Lines: Widely applied in various industrial automation production lines, such as in industries like automotive manufacturing, electronic device production, food and beverage processing, etc., to monitor and control various parameters in the production process, ensuring the stable operation of the production line and product quality.

Power Systems: In power systems, it can be used to monitor and control the operating status of power equipment, such as generators, transformers, switchgear, etc., to promptly detect and handle faults and abnormal situations in the power system, ensuring the safe and reliable operation of the power system.

Process Control Systems: Suitable for process control fields such as chemical engineering, petroleum, and natural gas, it can accurately measure and control parameters such as temperature, pressure, flow rate, and liquid level in the production process, realizing the automation and optimization of the production process.

Technical Parameters

Undervoltage Alarm Pickup: It is 0.85x the rated range, with a value range between 0.60 and 0.99x the rated value, and a step size of 0.01.

Startup U/V Alarm Pickup: It is also 0.85x the rated range, with the same value range and step size as the undervoltage alarm pickup.

Undervoltage Alarm Delay: The time is 3.0 seconds, which can be adjusted between 0.0 and 60.0 seconds, with a step size of 0.1 second.

Undervoltage Trip Sensor: The set value is 0.80x the rated range, with a value range between 0.60 and 0.99x the rated value, and a step size of 0.01.

Startup U/V Trip Sensor: It is 0.80x the rated range, with the same value range and step size as the undervoltage trip sensor.

Undervoltage Trip Delay: The time is 3.0 seconds, which can be adjusted between 0.0 and 60.0 seconds, with a step size of 0.1 second.

Application Fields

Industrial Automation Production Lines: Widely applied in various industrial automation production lines, such as in industries like automotive manufacturing, electronic device production, food and beverage processing, etc., to monitor and control various parameters in the production process, ensuring the stable operation of the production line and product quality.

Power Systems: In power systems, it can be used to monitor and control the operating status of power equipment, such as generators, transformers, switchgear, etc., to promptly detect and handle faults and abnormal situations in the power system, ensuring the safe and reliable operation of the power system.

Process Control Systems: Suitable for process control fields such as chemical engineering, petroleum, and natural gas, it can accurately measure and control parameters such as temperature, pressure, flow rate, and liquid level in the production process, realizing the automation and optimization of the production process.

Installation Method

Installation Location Selection: Select a place with good ventilation, dryness, no vibration, and far away from interference sources to install the module. It is usually installed on the standard DIN rail inside the control cabinet for easy wiring and maintenance.

Rail Installation: Snap the module onto the standard DIN rail, ensuring that the module fits closely with the rail. After snapping it in, check whether the module is firmly installed to prevent problems such as poor contact caused by looseness.

Wiring Method

Wiring Preparation: Prepare suitable tools, such as a screwdriver, wire stripper, etc., and wires that meet the requirements. The wire specification is generally single-strand or multi-strand copper wire ranging from 0.75mm² to 2.5mm². At the same time, ensure that the relevant power supply is cut off before wiring to ensure operational safety.

Signal Input Wiring: Connect the corresponding signal wires to the input terminals of the module according to the type and source of the input signal. For example, if it is a digital signal input, connect the positive and negative poles of the digital signal to the corresponding digital input terminals of the module respectively; if it is an analog signal input, connect it according to the wiring method of analog quantity input, and pay attention to distinguish different wiring methods, such as two-wire system, three-wire system, or four-wire system. Generally, for a two-wire system signal, the signal wire and the power wire need to be connected to the specific terminals of the module. In a three-wire system signal, the signal negative and the power supply M wire are common. For a four-wire system signal, there are separate power wires and signal wires, which are respectively connected to the corresponding terminals of the module.

Alarm and Trip Relay Wiring: Connect the connection wires of the alarm relay and the trip relay to the corresponding relay output terminals on the module as needed. These relays can be used to trigger external alarm devices or perform trip operations when specific faults or abnormal situations occur, to protect the safety of the equipment and the system.

Power Supply Wiring: Connect a suitable power supply to the power input terminal of the module to provide operating power for the module. Ensure that the voltage and current of the power supply meet the specifications of the module. Generally, the ABB GVC703AE01 input module requires a stable DC power supply to be connected.

Grounding Wiring: To ensure the safe operation and anti-interference ability of the module, reliably ground the grounding terminal of the module. The grounding resistance should meet relevant standards and requirements. Usually, the grounding resistance is required to be less than a certain value, such as 4 ohms or 10 ohms, etc.

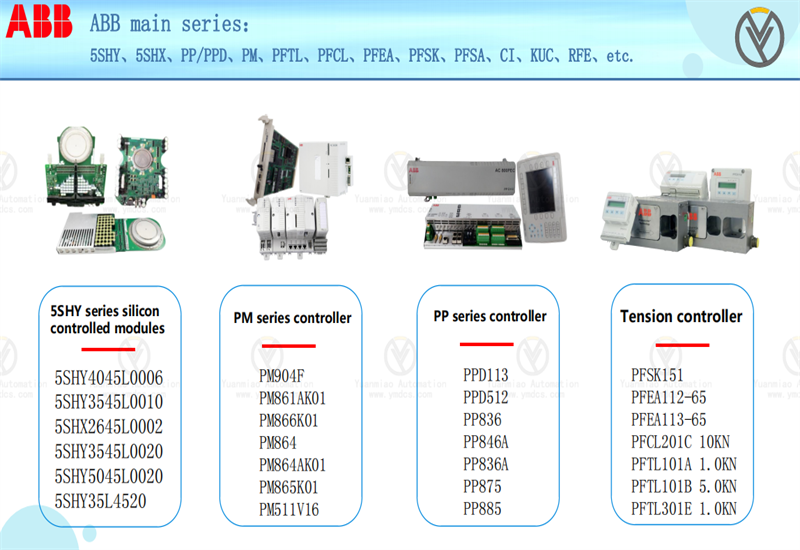

ABB Related Products

| CI857K01 3BSE018144R1 | CI538 3BSE015169R1 |

| CI854K01 3BSE025961R1 | CI540 3BSE001077R1 |

| CI868K01 3BSE048845R1 | CI858 3BSE018135R1 |

| CI858K01 3BSE018135R1 | CI546 3BSE012545R1 |

| CI860K01 3BSE032444R1 | CI547 3BNP004429R1 |

| CI861K01 3BSE058590R1 | CI840 3BSE022457R1 |

| CI862K01 3BUA000037R1 | CI560 3BUC980002R1 |

【 Disclaimer 】

We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.