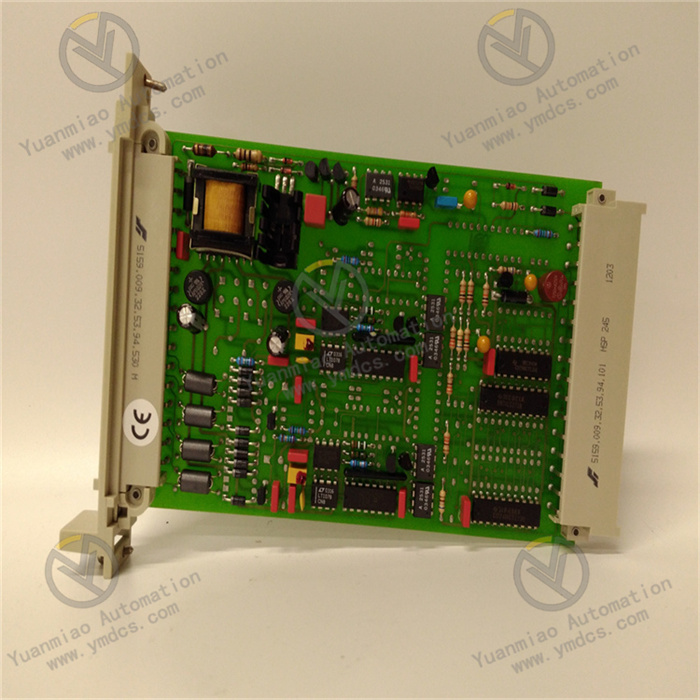

Description

GE IS200TRPAH2AHE

The GE IS200TRPAH2AHE is a high-end trip logic module developed for the Mark VIe industrial safety control system. Its core positioning is to provide an integrated solution of "safety interlock judgment + emergency shutdown control" for critical industrial equipment (such as gas turbines, steam turbines, and large compressors), and it undertakes the core role of "fault signal collection + logic calculation + trip command execution". Breaking the limitations of traditional discrete trip control, this module realizes real-time monitoring, priority judgment, and rapid intervention of multi-dimensional fault signals through highly integrated hardware logic and software configuration functions. It is widely used in scenarios with strict requirements for safety response speed and logic reliability, including steam turbine protection systems in power plants, safety interlocks for petrochemical reactors, emergency shutdown control for metallurgical rolling mills, and pressure protection for natural gas transmission pipelines.

The module adopts a "compact hardware architecture + triple redundant logic design", is suitable for standard rack installation of the GE Mark VIe system, and can seamlessly collaborate with components such as TRPG trip terminal boards and TMR (Triple Modular Redundancy) input modules. Its core advantages lie in the technical integration of "millisecond-level response" and "high safety redundancy": it has a built-in high-speed logic operation chip (response time ≤ 5ms) to ensure that trip actions are triggered within 100ms after a fault occurs; at the same time, it is equipped with a triple redundant power supply, triple redundant communication links, and a "two-out-of-three" voting logic circuit, completely eliminating misoperations or refusal to operate caused by single-point faults. With an operating temperature range of -30°C to +65°C, it can resist strong electromagnetic interference (such as inverter harmonics), voltage fluctuations, and dust erosion in industrial sites, building a "in-depth defense" safety protection system for complex industrial systems.

The module has the capability of "16 fault input channels + custom logic configuration", which can simultaneously collect multiple types of fault signals such as equipment over-temperature, over-pressure, excessive vibration, and sensor disconnection. It can configure priority judgment logic (e.g., "steam turbine overspeed" has higher priority than "low lubricating oil pressure") through GE Control Studio software. For example, in a gas turbine protection system, when both "rotational speed exceeding 115% of rated value" (level 1 fault) and "cooling water temperature exceeding 50°C" (level 2 fault) are detected simultaneously, the module will prioritize the level 1 protection action of "cutting off fuel supply + triggering emergency shutdown", and handle the level 2 fault only after the equipment is safely shut down, avoiding logic confusion under multiple faults. At the same time, it supports delayed filtering of fault signals (configurable from 0-1000ms), which effectively filters out transient false alarm signals caused by electromagnetic interference and improves the accuracy of logic judgment.

It adopts a full-link triple redundancy design of "power supply - communication - logic": 3 independent 24V DC power inputs are automatically switched through a redundant power management chip to ensure uninterrupted operation of the module in case of a single power supply fault; 2 Ethernet redundant links support the Profinet IRT protocol, and the backup link switches within ≤ 10ms when the main link fails, ensuring real-time data interaction with the Mark VIe system CPU; the core logic circuit adopts a "two-out-of-three" voting mechanism, which conducts majority voting on key fault inputs (such as 3 independent speed sensor signals) and only executes the trip action when 2 or more signals trigger a fault, completely eliminating false shutdowns caused by single-point sensor faults. For example, in steam turbine speed protection, if one speed sensor falsely reports "overspeed", the module will ignore the signal and only trigger a shutdown when 2 or more sensors confirm overspeed, greatly improving the operational reliability of the system.

With a built-in high-speed FPGA logic operation chip, the full-process response time from fault signal collection, logic judgment to trip command output is ≤ 100ms, which is 50% faster than traditional PLC-based trip systems, and can effectively prevent the expansion of malignant accidents such as steam turbine overspeed and reactor over-pressure. At the same time, the module supports the "fault event recording" function, which can store 1000 pieces of historical fault information (including "fault type + occurrence time + trigger channel + handling action"). Through GE Proficy Historian software, the fault timing curve can be queried remotely, facilitating maintenance personnel to trace the cause of the accident. For example, after an explosion accident of a chemical reactor, the timing data of "pressure over-limit → rapid temperature rise → trip trigger" recorded by the module can be used to quickly locate the source of the accident (such as jamming of the feed valve) and provide a basis for subsequent improvements.

It is deeply compatible with the GE Mark VIe control system, can be directly connected to the system's TMR architecture, and realizes plug-and-play with components such as TRPG trip terminal boards and TTUR speed monitoring modules without additional protocol conversion equipment. At the same time, it supports the integration of third-party equipment, and can communicate with systems such as Siemens S7-1500 PLC and Rockwell ControlLogix through the Modbus RTU protocol, uploading data such as fault status and trip actions to third-party monitoring platforms. In addition, it supports modular expansion: 16-channel digital input modules (such as IS200DIAH1A) can be expanded through the CANopen interface, and the maximum number of input channels can be expanded to 64, adapting to centralized protection scenarios for multiple equipment in large petrochemical parks and power plants, and significantly reducing system construction costs.

The maintenance design focuses on "balancing safety and efficiency": it supports online firmware upgrades (completed remotely via Ethernet) to update logic algorithms without powering off; it has a built-in self-diagnosis function that continuously monitors the status of the module's power supply, communication interface, and relay contacts. When faults such as "relay contact adhesion" and "communication link interruption" are detected, it immediately triggers local sound and light alarms (flashing red LED + intermittent buzzer alarm) and sends fault codes (such as "E03 - Relay Output Fault") to the upper computer, facilitating maintenance personnel to conduct timely troubleshooting. Meanwhile, it adopts a pluggable terminal block design, so there is no need to disconnect wires when replacing the module. With clear terminal labels (such as "IN1 - Speed Over-Temperature", "OUT1 - Fuel Cut-Off Valve"), maintenance personnel can replace a faulty module in only 5 minutes, significantly reducing system downtime.

![]()