Description

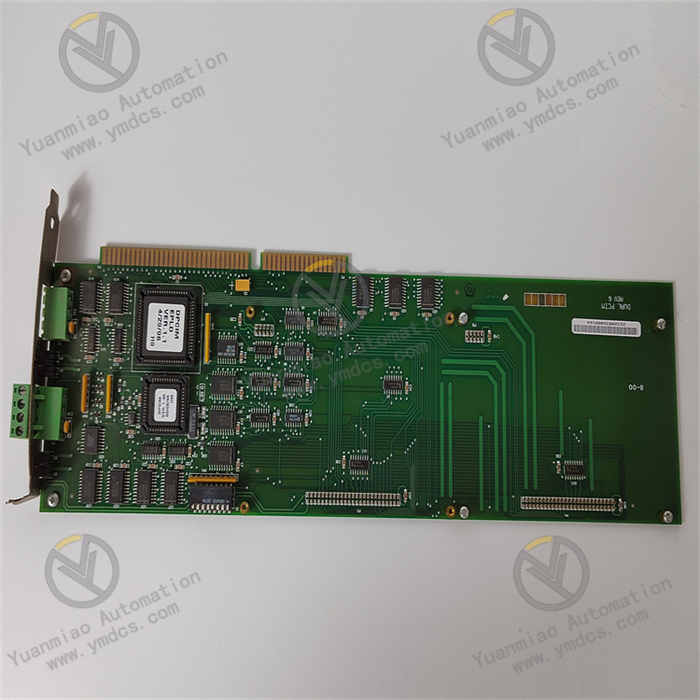

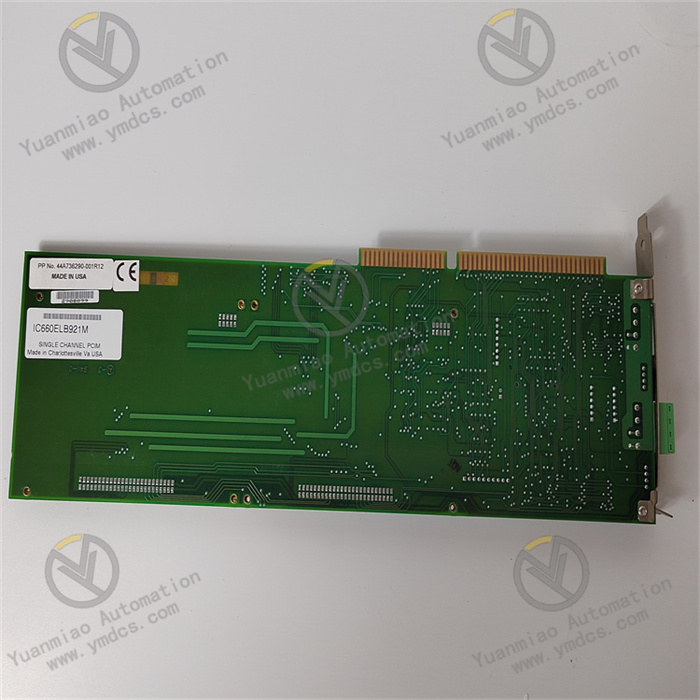

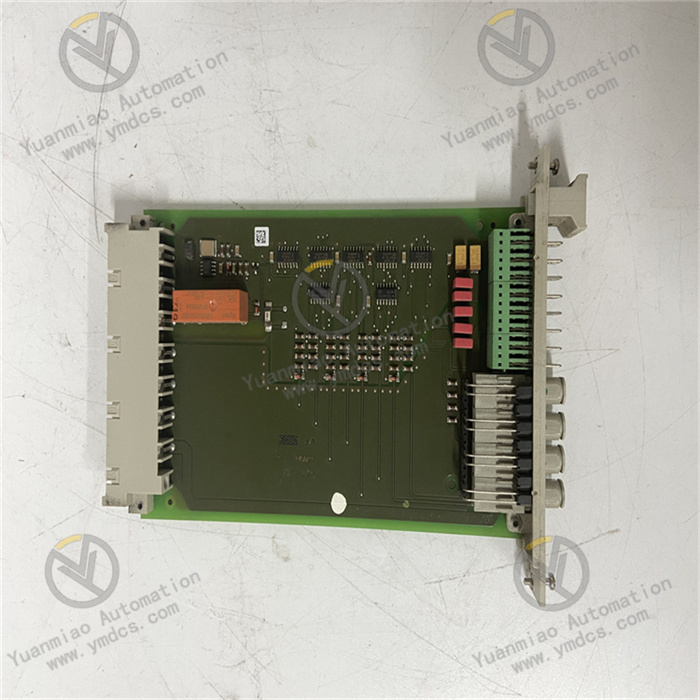

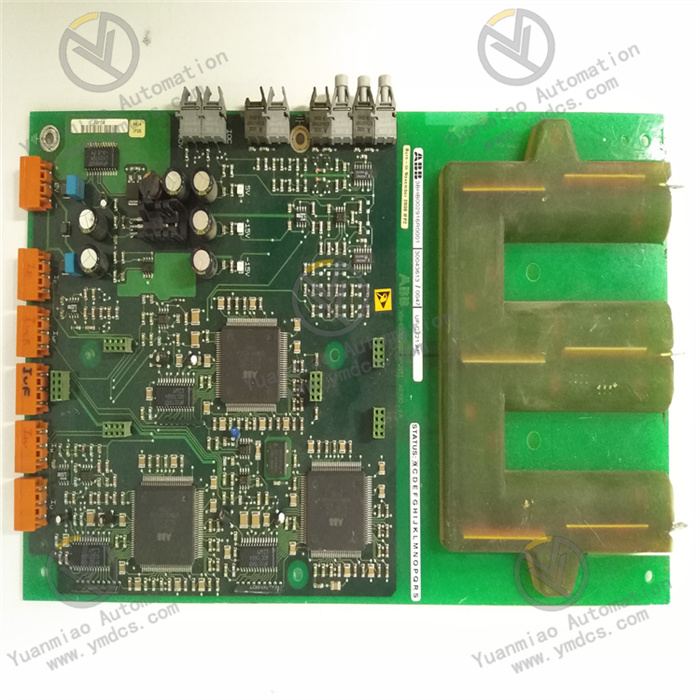

GE Fanuc IC660ELB921M

I. Overview

GE Fanuc IC660ELB921M is a single-channel PC Interface Module (PCIM) belonging to the Genius I/O series. Manufactured by GE Fanuc, Emerson Automation is also involved in the related business of this module currently. Specifically designed for industrial automation and process control systems, it can provide reliable input/output control and data interaction support for various complex industrial scenarios.

The core positioning of this module is to serve as a bridge between PCs and the Genius I/O bus, enabling convenient connection of IBM PC, XT, and AT-type personal computers to the Genius I/O system. It is equipped with only a single channel, allowing connection to just one Genius bus at a time; however, this design ensures the stability and specificity of signal transmission. In industrial production, it can be used to connect upper computers in workshops to the Genius I/O network, realizing centralized control and management of remote I/O devices. For example, in an automobile parts manufacturing workshop, with this module, the upper computer can accurately control I/O devices distributed at different workstations, achieving automated control of the production process and improving production efficiency and product quality.

Compared with dual-channel PCIM modules in the same series, the IC660ELB921M has a more compact structure and lower cost, making it suitable for small-scale industrial control systems that do not require a large number of channels and pursue high cost-effectiveness. When compared with modules with similar functions from other brands, it has stronger compatibility with various devices under GE Fanuc. Without the need for complex adaptation and debugging work, it can work in coordination with GE Fanuc Genius bus controllers, handheld displays, and other equipment. This reduces the time and cost of system setup while ensuring the stability and reliability of system operation.

II. Technical Specifications

(I) Core Communication and Interface Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Communication Protocol | Compatible with multiple Genius communication protocols, meeting different industrial communication requirements and ensuring the accuracy and stability of data transmission. |

| Communication Rate | Supports standard baud rates of 38.4K, 76.8K, 153.6K, as well as an extended baud rate of 153.6K. It can be flexibly adjusted according to actual application scenarios and transmission distances to ensure efficient data transmission. |

| Interface Type | Adopts an AT-style interface board, which can be seamlessly adapted to IBM PC, XT, and AT-type personal computers for easy system integration; equipped with one interface for connecting to the Genius bus to realize communication with external I/O devices. |

| Number of Slots | Features a single-slot design with a compact structure and small space occupation, suitable for installation environments with limited space such as control cabinets. |

| Compatible Daughter Cards | Can be used with daughter cards such as IC660ELB912. Functions can be expanded through daughter cards, such as connecting more external devices, to enhance the application flexibility of the module. |

(II) Electrical and Power Supply Parameters

- Power Supply Requirements: The operating voltage is 5V DC, with a current requirement of 400mA. It has high requirements for power supply stability, and the voltage fluctuation range must be controlled within ±10% of the nominal value to ensure the normal operation of the module and avoid data transmission errors or module failures caused by unstable voltage.

- Bus Load and Driving Capacity: The bus load of each input line is 1 LSTTL, ensuring stable reading of input signals; the bus driving capacity of each output line is 10 LSTTL, which can effectively drive external loads and ensure that output signals can reliably control external devices.

- Power Consumption: The overall power consumption is low. During long-term operation, it generates little heat, reducing heat dissipation costs and the risk of equipment overheating, thus ensuring the continuous and stable operation of the system.

(III) Performance and Memory Parameters

- Data Processing Capacity: It can manage errors of at least 30 bus devices. During system initialization, it conducts comprehensive detection and management of devices, promptly identifies and addresses potential issues, and ensures the stable operation of the system. It can use 8,000 input positions and 8,000 output positions, providing sufficient I/O resources for complex industrial control scenarios and meeting diverse control requirements.

- Memory Requirements: The main board requires 4 bytes of memory for storing key operating parameters and control instructions; the daughter card requires 16 KB of memory for caching and processing data, ensuring fast data reading/writing and efficient data processing.

- Configuration Software Support: Configuration software is provided with the module, which can configure the daughter card independently of the main board. Users can flexibly set daughter card parameters (such as communication rate and device address) according to actual needs, improving the adaptability and application flexibility of the module.

(IV) Environmental Parameters

- Operating Temperature: The operating temperature range is -40℃ to +70℃, enabling it to operate stably in harsh industrial environments with extremely low or high temperatures. It can run stably whether in cold factory workshops in northern winters or hot chemical production sites in southern summers.

- Storage Temperature: The storage temperature range is -40℃ to +85℃, ensuring that the module's performance remains unaffected within a wide temperature range during long-term non-use or transportation.

- Humidity Range: The humidity adaptation range is 5% to 95% (non-condensing), complying with the IEC 60068-2-3 standard. It can work normally in humid industrial environments, such as textile factories and food processing plants where humidity is relatively high.

III. Functional Features

(I) Convenient System Integration and Compatibility

- PC System Adaptation: As an AT-type interface board, it can be easily integrated into microprocessor systems developed by users and seamlessly connected to IBM PC/AT/XT series computers. For example, in a small-scale automated production line control system, engineers can quickly integrate the IC660ELB921M into a PC-based control system to achieve automated control of production line equipment.

- Genius Ecosystem Compatibility: It is highly compatible with Genius communication protocols and communication timings, and can work in collaboration with any GE Fanuc Genius bus controller. It is also fully compatible with handheld displays. On industrial sites, operators can conveniently view and set parameters of the Genius I/O system connected via this module through handheld displays, realizing on-site debugging and monitoring of devices.

- Flexible Daughter Card Configuration: The single daughter card equipped with the module can be configured independently of the main board using the accompanying configuration software. The daughter card can be connected to Genius bus devices independently and act as a universal I/O controller for the I/O system. For example, in factory equipment renovation projects, daughter card parameters can be flexibly set according to the needs of newly added equipment to realize the connection and control of new equipment without the need for large-scale modifications to the entire system.

(II) Efficient Data Transmission and Processing

- Multi-Rate Communication: It supports multiple communication rates, and the appropriate baud rate can be selected based on actual application scenarios. In device control scenarios where the data transmission distance is short and real-time performance is critical, the extended baud rate of 153.6K is used to achieve fast data transmission and ensure timely device response. In environments with long transmission distances and significant interference, lower baud rates of 38.4K or 76.8K are selected to ensure the stability of data transmission.

- Data Storage and Interaction: It has 8,000 input positions and 8,000 output positions, which can store large amounts of input and output data to meet the data volume requirements of complex industrial control logic. When the module is configured for input-only, it can quickly read Genius block information to provide data support for system decision-making; when configured for output-only, it can accurately write Genius block outputs to realize the control of external devices.

(III) Reliable Adaptability to Industrial Environments

- Wide-Temperature Operation: The wide operating temperature range of -40℃ to +70℃ allows it to operate stably in various extreme temperature environments. In cold cold-chain logistics control systems, even when the ambient temperature is as low as -30℃, the module can still work normally, ensuring the stable operation of automated cargo storage and retrieval equipment. In high-temperature steel smelting workshops, when the temperature reaches 60℃, the module will not experience performance degradation or failures, ensuring the continuity of the production process.

- Humidity Resistance: The humidity adaptation range of 5% to 95% (non-condensing) enables it to work normally in humid environments. In industrial sites with high humidity such as paper mills, the module will not experience issues such as short circuits or corrosion due to humidity, ensuring the long-term stable operation of the system.

(IV) Intelligent Diagnosis and Fault Management

- Device Error Management: During initialization, it can control tasks accordingly and manage errors of at least 30 bus devices, promptly identifying and reporting device failures. For example, when a connected I/O device malfunctions, the module can quickly detect it and send fault information to the upper computer through indicator lights or communication interfaces, facilitating maintenance personnel to quickly locate and repair the problem.

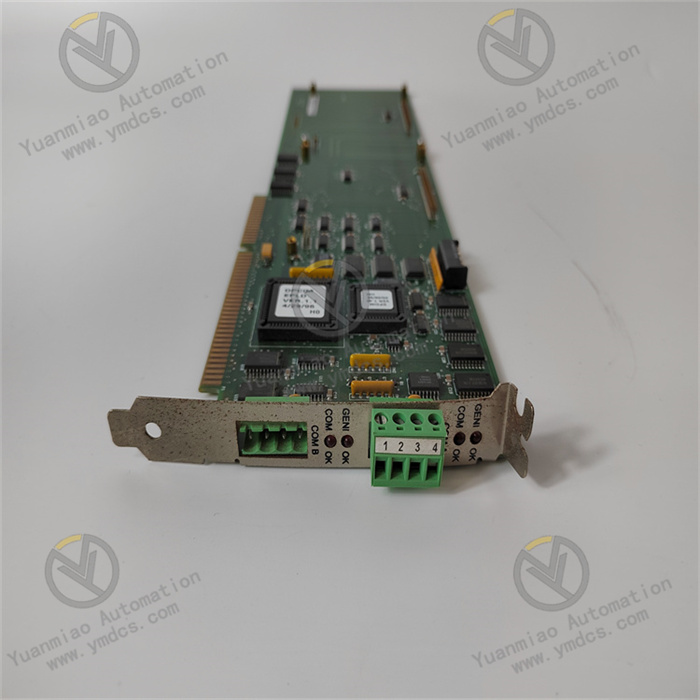

- Status Indication: Each daughter card is equipped with 2 LEDs for intuitively indicating the card's status and communication process. A steady green LED indicates that the card is working normally, a flashing green LED indicates ongoing data communication, and a red LED indicates a fault. Maintenance personnel can quickly determine the working status of the module by observing the LED status, improving the efficiency of fault diagnosis.