Description

ABB CP501 1SBP260170R1001

I. Product Overview

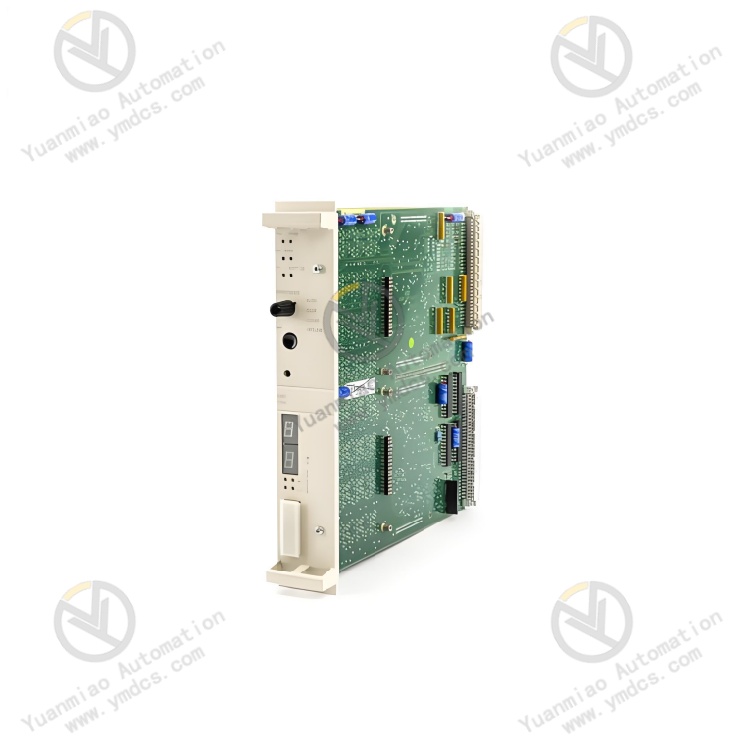

ABB CP501 (1SBP260170R1001) is a compact control panel whose core function is to provide an intuitive human-machine interface (HMI) for industrial automation systems, enabling parameter setting, status monitoring, operation command input, and fault information display. As a key interactive medium between operators and control systems, this panel requires configuration with the dedicated CP500 programming software. It can seamlessly interface with ABB AC 500 series PLCs and industrial control devices supporting the Modbus protocol.

Boasting an IP65 high protection rating, flexible programming features, and stable operating performance, it is widely used in various industrial fields such as water treatment, machinery manufacturing, food and beverage, heating, ventilation and air conditioning (HVAC), and marine equipment. It is particularly suitable for scenarios with high requirements for operational interface simplicity and environmental adaptability.

The product adopts a Germany-originated industrial-grade hardware architecture, equipped with a 2-line × 16-character STN backlit LCD text display and 4 programmable function keys. It integrates low-power consumption design and multiple safety protection features. Its ultra-thin and compact structure is suitable for front-panel embedded installation, occupying minimal installation space.

II. Functional Features

1. Clear and Intuitive Human-Machine Interface Design

2. Flexible Communication Adaptability and System Integration

3. High Protection Rating and Industrial-Grade Environmental Adaptability

4. Safe and Reliable Authority Management and Data Storage

5. Compact Design and Easy Installation

III. Technical Parameters

| Category | Specific Parameters |

|---|---|

| Model/Part Number | Model: CP501; Part Number: 1SBP260170R1001 |

| Manufacturer | ABB (Country of Origin: Germany) |

| Product Type | Industrial-grade text control panel (CP500 series) |

| Core Functions | Text information display, programmable key operation, parameter setting, status monitoring, fault alarm, 8-level authority management |

| Display Parameters | Display Type: STN text LCD; Display Specification: 2 lines × 16 characters; Character Height: 5mm; Display Feature: Backlit; Screen Size: 2.5 inches |

| Operation Keys | 4 programmable function keys supporting customized operation logic |

| Storage Parameters | User Program Memory: 16KB Flash EPROM; User Data Memory: 16KB non-volatile RAM |

| Communication Parameters | Communication Protocols: Modbus RTU, Modbus ASCII and other compatible protocols; Communication Interfaces: 2 serial communication interfaces; Communication Baud Rate: 4.8~187.5 kbd |

| Power Supply Parameters | Supply Voltage: 24VDC (Adaptation Range: 18~32VDC); Power Consumption: 4.8 VA |

| Environmental Adaptability | Operating Temperature: 0~+50℃; Storage Temperature: -20~+70℃; Relative Humidity: 5%-95% (non-condensing); Protection Rating: IP65; Electromagnetic Interference Resistance: Compliant with relevant industrial EMC standards |

| Physical Parameters | Net Dimension (W×H×D): 104mm×69mm×28mm; Installation Depth: 37.5mm; Net Weight: 0.2kg; Gross Weight: 0.3kg; Installation Method: Front-panel embedded installation (non-DIN rail installation) |

| Compatible Systems | ABB AC 500 series PLCs, third-party industrial control devices supporting Modbus RTU/ASCII protocols |

| Programming Requirements | Configuration requires the use of dedicated CP500 programming software |

| Application Scenarios | Industrial automation HMI scenarios such as water treatment, machinery manufacturing, food and beverage, HVAC, marine equipment, and automated production lines |

IV. Working Principle

Configuration Initialization: Complete user program configuration through the dedicated CP500 programming software, including function key definition, display interface layout, parameter range setting, communication parameter configuration, authority level division, etc. Download the configuration program to the panel's built-in Flash EPROM memory, and the panel automatically loads the configuration program after startup.

- Data Communication Interaction: The panel establishes a stable communication link with the upper control system (e.g., AC 500 PLC) through the serial communication interface, and transmits data in real time according to the preset Modbus protocol. On the one hand, it receives information such as equipment operating status, process parameters, and fault codes uploaded by the control system; on the other hand, it transmits the operator's key commands to the control system.

Operation Command Parsing: When the operator presses a function key, the panel's built-in processing unit parses the configured function corresponding to the key, generates the corresponding control command, and sends it to the upper control system through the communication link, triggering corresponding operations such as parameter modification, equipment start-stop, and fault reset.

- Information Display Feedback: After receiving the data uploaded by the control system, the panel parses it through the internal processing unit, and clearly displays information such as equipment operating status and parameter values in text form on the 2-line × 16-character LCD display. If fault information is detected, the fault code and description are immediately highlighted on the display, and the fault handling process of the control system can be triggered through the linkage of function keys.

- Security Authority Control: During critical operations such as parameter modification, the panel automatically triggers the authority verification process. The operator must enter the password of the corresponding level to complete the operation. Unauthorized operations will be rejected by the system, and an "insufficient authority" prompt will be displayed on the screen to ensure the safe operation of the control system.

V. Operation Guide

1. Installation Steps

Installation Environment

Mechanical Installation

Wiring Operation

2. System Configuration and Debugging

Configuration Programming

Debugging and Verification

3. Operation and Maintenance

Daily Operation

Regular Maintenance

- Weekly: Wipe dust and stains on the panel surface with a dry soft cloth, focusing on cleaning the display screen area to ensure clear display. Check the flexibility of key operations to ensure no jamming. Observe the backlight brightness of the display screen to ensure it meets the observation requirements.

- Monthly: Connect to the panel through the programming software to back up the current configuration program and user data. Check the stability of the power supply voltage to ensure normal power supply. Test the stability of the communication link and verify that there are no abnormalities in the communication parameters. Verify the effectiveness of the authority management function.

- Annually: Conduct a comprehensive inspection of the panel by professional personnel to check for aging or oxidation of internal wiring. Verify the display effect of the screen and the response sensitivity of the keys, and handle problems such as blurred display or stuck keys in a timely manner. Check the protective sealing performance to ensure that the IP65 protection rating is not affected. If there is a potential fault risk in the panel, contact ABB after-sales service in a timely manner for repair or replacement.

4. Common Fault Troubleshooting

| Fault Phenomenon | Possible Causes | Troubleshooting Methods |

|---|---|---|

| No display on the screen and no response from keys | Power supply failure, incorrect power wiring, loose terminals, damaged internal power module of the panel | Check whether the supply voltage is 24VDC (adaptation range: 18~32VDC). Verify the correctness of the positive and negative pole wiring of the power supply. Retighten the power terminal screws. Test with a backup power supply; if there is still no response, contact after-sales service to repair the internal power module |

| Blurred display/backlight not working | Damaged backlight module, unstable supply voltage, excessive or insufficient ambient light | Check the stability of the supply voltage and add a power stabilizer if necessary. Adjust the installation position to avoid direct sunlight. If the backlight still does not work, contact after-sales service to replace the backlight module |

| Communication failure, unable to interact with the control system | Incorrect communication parameter configuration, damaged communication cable, loose terminals, protocol mismatch | Recheck the communication protocol, communication baud rate, address and other parameters. Check the integrity of the communication cable connection and test with a backup communication cable. Retighten the communication terminal screws. Confirm that the communication protocol of the panel is consistent with that of the control system |

| No response from function key operation | Stuck keys, incorrect configuration program, insufficient authority level | Check whether the keys are stuck and clean foreign objects around the keys. Verify the correctness of the function key definition in the configuration program through the programming software and retest by re-downloading the program. Confirm the operator's authority level and retry after entering the corresponding password |

| Unable to save parameters/data loss | Non-volatile RAM failure, incorrect configuration program, abnormal power failure | Check the stability of the power supply to avoid abnormal power failure. Re-download the configuration program and back it up. If the problem persists, contact after-sales service to repair the memory module |

| Displayed information is inconsistent with the actual equipment status | Communication data transmission error, incorrect parameter association in the configuration program, control system failure | Check whether there is packet loss in the communication link and enhance anti-interference measures. Verify the association relationship between parameters in the configuration program and variables in the control system. Detect the operating status of the control system and troubleshoot control system faults |