Description

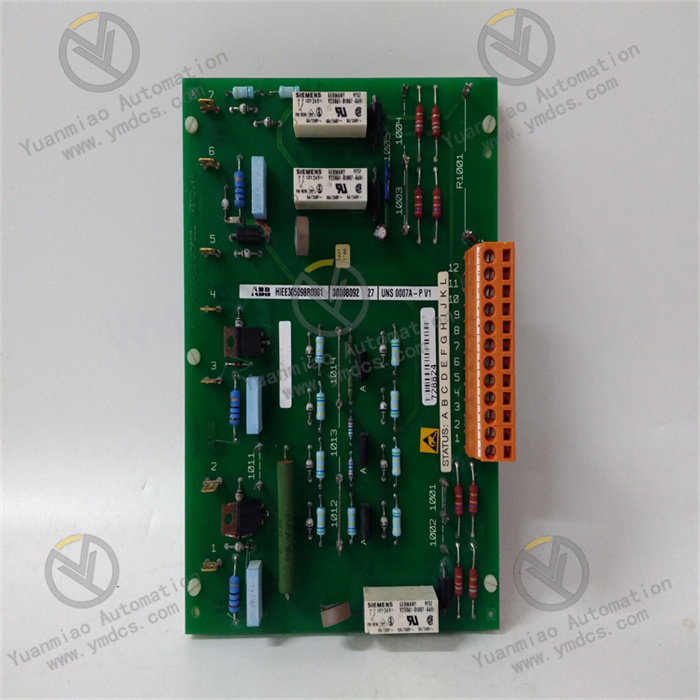

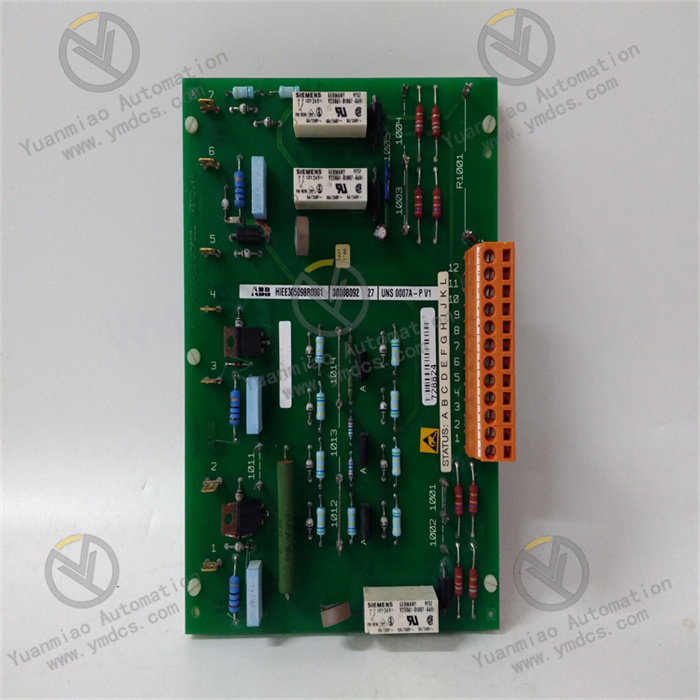

ABB DC375a GJR2304400R1

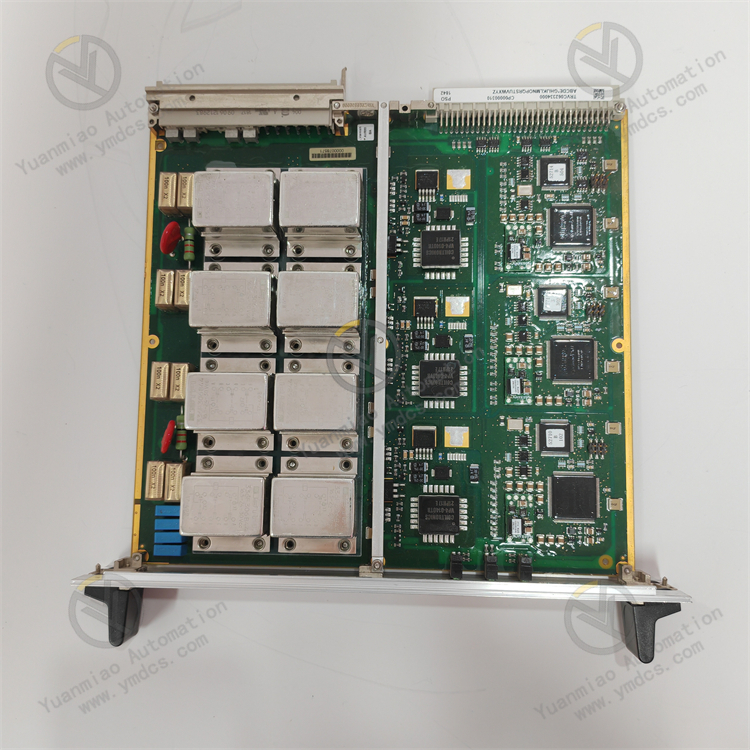

ABB DC375a (Order Number: GJR2304400R1) is a high-performance digital input/output (I/O) module belonging to the ABB ProControl series and compatible with the Advant OCS (Open Control System) architecture. As a core signal interaction component in industrial automation distributed control systems (DCS), this module focuses on the accurate acquisition of on-site digital switching signals and reliable output of control commands. With excellent electrical isolation performance, flexible parameter configuration and industrial-grade stability, it is widely used in industrial scenarios with stringent requirements for signal interaction reliability, such as power generation, metallurgy and chemical industries, providing efficient data transmission support for equipment interconnection and process control.

1. Product Attributes

As a classic I/O component of the ProControl series, this module is positioned as a multi-channel digital signal processing unit, with core functions covering digital input acquisition and output control. The specific basic information is as follows:

- Product Model: DC375a (Order Number: GJR2304400R1)

- Product Type: Integrated digital input/output (DI/DO) module, belonging to the ABB ProControl module family

- Core Purpose: Collect digital switching signals from on-site devices such as sensors and limit switches, and output control commands to drive actuators including contactors and solenoid valves, realizing bidirectional signal interaction between the control system and on-site equipment

2. Technical Specifications

2.1 Electrical Performance Parameters

- Channel Configuration: A single module supports up to 16 digital input channels, and each input channel can be independently configured with signal response parameters to meet the simultaneous monitoring requirements of multiple devices.

- Input Power Supply and Signal Range: Compatible with 24V DC standard industrial power supply, with clear signal thresholds: the 0 signal corresponds to -3V ~ +5V, the 1 signal corresponds to +15V ~ +30V, and the range of +5V ~ +15V is defined as an uncertain signal interval, effectively avoiding signal misjudgment. The input current of each channel varies with voltage, with a typical value of 5mA at 24V and no more than 8mA at 30V, achieving excellent power consumption control.

- Signal Delay and Configuration: The typical input signal delay is 8ms, supporting stepless configuration within the range of 0.1ms ~ 32ms. It can be adjusted according to the response speed of on-site equipment, balancing signal real-time performance and anti-interference capability.

- Electrical Isolation and Protection: The input channels are electrically isolated from other circuits of the module, effectively blocking ground loops and electromagnetic interference. A built-in varistor surge protection component clamps the input voltage at approximately 36V, preventing module damage caused by peak voltage and improving adaptability to harsh working conditions.

2.2 Physical and Installation Specifications

- Installation Method: Supports mounting plate fixed installation, recommended to be fastened with M6 screws at a tightening torque of 10Nm, with a mounting hole diameter of 6.5mm, ensuring firm installation under vibration conditions.

- Space and Heat Dissipation Requirements: To ensure heat dissipation efficiency, a 10mm free space shall be reserved on the terminal side of the module, and 30mm free space on other sides. Avoid direct blowing of hot air from other equipment to the module to ensure smooth ventilation.

- Grounding Requirements: The module frame shall be reliably grounded to the mounting plate through a grounding wire with a cross-sectional area of not less than 4mm². It is recommended to use serrated washers to improve grounding contact effect, which not only ensures personal safety but also enhances electromagnetic interference suppression capability.

Cable Compatibility: Supports both shielded and unshielded cable connections. The maximum transmission distance of shielded cables can reach 1000m, and that of unshielded cables is up to 600m, meeting the requirements of long-distance on-site signal transmission.

2.3 Environmental Adaptability

- Operating Temperature Range: -10℃ ~ +50℃, meeting the environmental requirements of most industrial control rooms and on-site cabinet rooms.

- Relative Humidity: Not exceeding 95% (non-condensing), avoiding circuit short circuits caused by humid environments.

- Vibration Resistance: Can withstand slight vibration and impact. Avoid installation near equipment with strong vibration to prevent connection loosening and module damage.

3. Compatible Systems and Hardware Combinations

- Compatible Control Systems: Core compatibility with ABB ProControl series control systems and Advant OCS open control systems. Channel parameter configuration, signal status monitoring and fault diagnosis can be realized through system software.

- Supporting Hardware: Needs to be used with standard industrial 24V DC power modules, shielded signal cables and special mounting plates. The grounding system shall form a unified loop with other on-site equipment to improve overall anti-interference performance.

- Signal Interaction: The input side is compatible with digital sensors such as proximity switches, photoelectric switches and limit switches, and the output side can drive actuators including contactors, relays and solenoid valves, forming a complete signal acquisition-control closed loop.

4. Product Features

4.1 Flexible Configuration for Diversified Scenarios

The module's input delay can be precisely adjusted within a wide range to adapt to on-site equipment with different response speeds. The 16-channel multi-channel design enables centralized acquisition and control of single-point or multi-point signals without additional expansion modules, reducing system construction costs. It also supports Type 1 input in compliance with EN 61131-2 standard, covering mainstream industrial digital equipment with its compatibility.

4.2 Industrial-grade Reliability and Excellent Anti-interference Capability

Adopting a dual design of electrical isolation and surge protection, it effectively resists electromagnetic radiation, ground loops and other interferences in industrial sites, avoiding signal distortion and module damage. Industrial-grade components and packaging processes ensure long-term stable operation of the module under wide temperature and high humidity environments, with a long mean time between failures (MTBF), meeting the reliability requirements of continuous production scenarios. Each channel is equipped with a yellow LED indicator, which lights up when the signal is at a high level, enabling intuitive monitoring of the working status of each channel for quick fault diagnosis.

4.3 Easy Installation and Efficient Operation & Maintenance

5. Application Scenarios and Safety Precautions

5.1 Application Scenarios

5.2 Safety and Operation Precautions

- Installation and maintenance work must be performed by qualified electricians. Before operation, all voltage sources must be disconnected, and the Lockout-Tagout (LOTO) procedure must be implemented. After disconnecting the external power supply, wait for 5 minutes to allow internal capacitors to discharge completely before operation to avoid electric shock hazards.

- Before installation, confirm that the ambient temperature, humidity, vibration and pollution level meet the module requirements. Ensure that the installation area is well-ventilated, free of corrosive gases, flammable and explosive materials to prevent the module performance from being affected by the environment.

- During wiring, check the terminal definitions to ensure that power and signal cables are firmly connected and correctly corresponding. In particular, the grounding cable must meet the cross-sectional area requirements to avoid signal abnormalities and module damage caused by poor contact or wiring errors.

- The module contains high-voltage circuits inside. Unauthorized disassembly by non-professionals is strictly prohibited. Maintenance must be entrusted to qualified professional institutions to avoid equipment damage and safety accidents.