Description

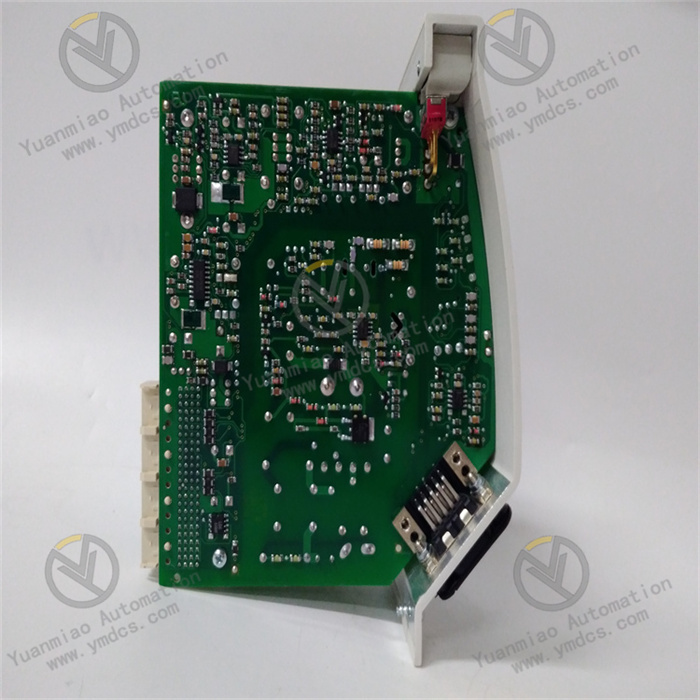

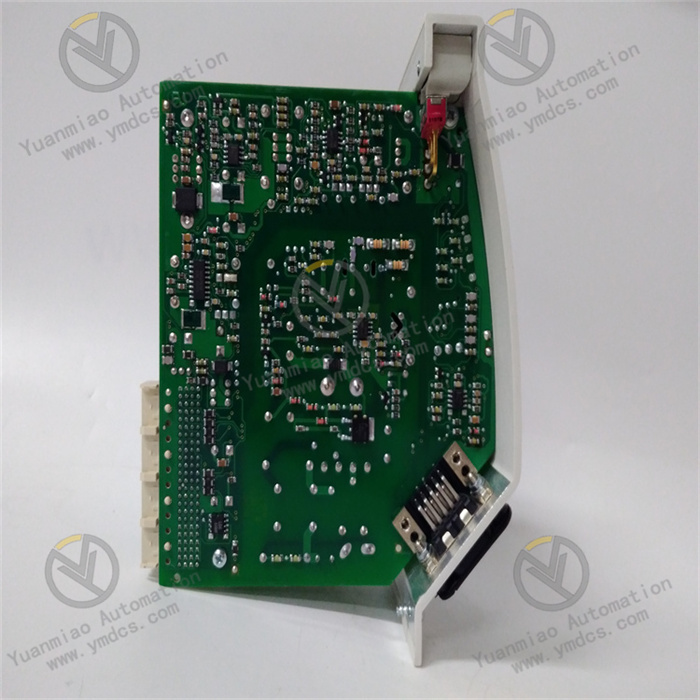

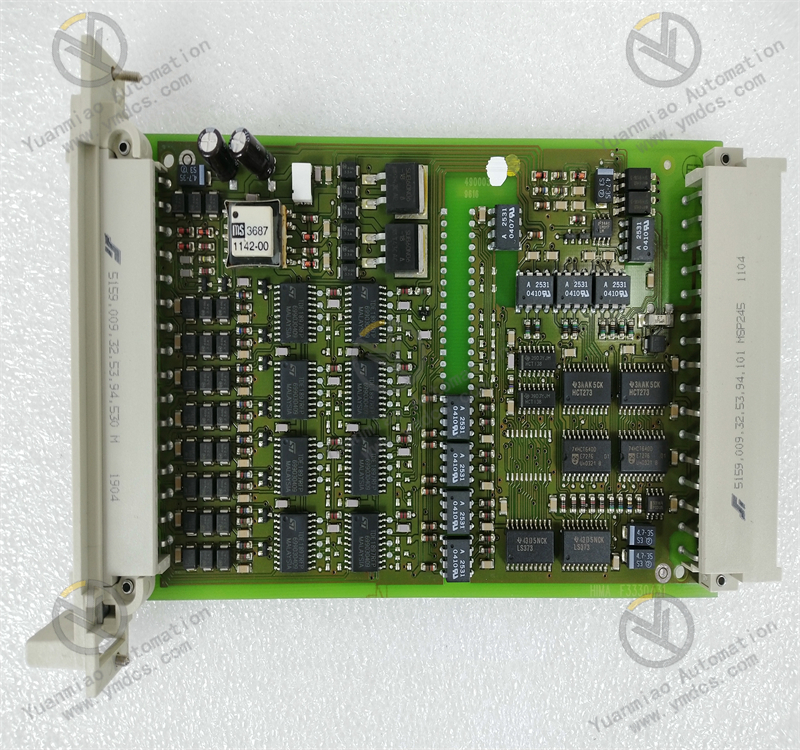

ABB SD831 3BSC610064R1

I. Overview

ABB SD831 3BSC610064R1 is a switching power supply module, with its core positioning as a wide-voltage input, high-stability 24V DC power supply unit. Designed specifically for industrial automation control systems, this module supports wide-range AC/DC input and outputs stable 24V DC power. It features redundant expansion capability and compact installation characteristics, and can directly provide reliable power supply for I/O modules, controllers and field sensors of DCS systems such as ABB Advant OCS and Symphony Plus. It is a key power component to ensure the continuous operation of industrial control systems.

II. Core Features

Wide-range AC/DC Input Adaptation: Compatible with wide voltage input of AC 100-240V and DC 110-300V, no manual voltage gear switching is required. It can adapt to power supply environments in different regions and scenarios, reducing the complexity of on-site deployment.

Stable Output and Redundant Expansion: Outputs standard 24V DC power with a rated output current of 3A, featuring high power supply precision and low ripple, which can meet the power supply requirements of precision industrial control equipment. It supports linkage with SS8xx series voting units to easily build a redundant power supply architecture and improve the anti-failure capability of the system.

Compact Installation and Convenient Operation & Maintenance: Adopts DIN rail mounting design with a compact structure, measuring only 32mm (width) × 124mm (height) × 102mm (depth) and weighing about 0.52kg, which can efficiently utilize the space of the control cabinet. Equipped with intuitive status indicators, it is convenient to quickly judge the operation status and facilitate maintenance.

Industrial-grade Reliability and Compliance: Adopts industrial-grade component packaging, with strong resistance to electromagnetic interference and voltage fluctuations, and can operate stably for a long time in harsh industrial environments. It complies with EU RoHS directive (2011/65/EU) and G2 standard, meeting the requirements of environmental protection and industry specifications.

- Multi-layer Safety Protection Design: Built-in overcurrent, short-circuit and reverse connection protection circuits, which can effectively resist damage to the module and subsequent equipment caused by abnormal power supply. The field side and system side have good electrical isolation performance, further improving power supply safety and anti-interference capability.

III. Technical Parameters

| Parameter Name | Specification |

|---|---|

| Product Model | ABB SD831 3BSC610064R1 |

| Product Type | Industrial-grade Switching Power Supply Module |

| Input Voltage Range | AC 100-240V or DC 110-300V |

| Output Parameters | DC 24V, rated output current 3A |

| Mounting Method | DIN Rail Mounting |

| Dimensions | 32mm (W) × 124mm (H) × 102mm (D) |

| Product Weight | Approximately 0.52kg |

| Operating Environment | Temperature 0℃-55℃, relative humidity 5%-95% (non-condensing), protection class IP20 |

| Redundant Configuration | Supports connection with SS8xx series voting units to realize redundant power supply |

| HS Code | 850440 (Electrical transformers, static converters and inductors) |

IV. Working Principle

The core working principle of ABB SD831 3BSC610064R1 module is a closed-loop power supply process of wide-range input conversion - voltage stabilization and filtering - output protection - status monitoring. Through the coordination of internal circuits, it realizes the conversion from AC/DC input to stable 24V DC output, while ensuring power supply safety and reliability. The specific working process can be divided into four core stages:

Stage 1: Input Adaptation and RectificationThe module receives wide-range voltage of AC 100-240V or DC 110-300V through the input terminal. If it is AC input, it is converted into DC power through the built-in rectifier circuit. At the same time, the input filter circuit filters out interference clutter in the power grid, suppresses voltage fluctuations, and provides a pure power signal for subsequent voltage stabilization processing.

Stage 2: Voltage Stabilization and Power ConversionThe preprocessed power signal enters the core voltage stabilization unit, which performs power conversion and precise voltage stabilization through switching power supply technology, stabilizes the voltage at the rated output value of 24V DC, and controls the output current not to exceed the rated value of 3A, ensuring the stability and consistency of the output power supply to meet the power supply requirements of subsequent equipment.

Stage 3: Output Protection and IsolationThe stabilized 24V DC power is supplied to subsequent equipment through the output terminal. The built-in overcurrent, short-circuit and reverse connection protection circuits monitor the output status in real time. If an abnormality is detected, the output is cut off or the current is limited immediately to avoid damage to the module and subsequent loads. At the same time, electrical isolation design realizes the isolation between the field side and the system side, improving anti-interference ability and safety.

V. Common Fault Troubleshooting

1. No Module Output, Subsequent Equipment Power-off

2. Unstable Output Voltage, Abnormal Operation of Subsequent Equipment

3. Switching Failure After Redundant Configuration, Power Supply Interruption